Connecting Low Voltage Inputs

The LiteKeeper-8

®

logic board can support up to 64 switch

inputs. Of these 64 inputs, 8 of them may be dry contact clo-

sure inputs that are connected to the terminal blocks on the

left side of the LiteKeeper

®

Logic Board. Digital switch inputs

may also be used on the LiteKeeper

®

. If no contact input type

switches are being used, the full 64 switch inputs may consist

of digital switches. If a combination of contact input switches

and digital switches are being used, the combined total cannot

exceed 64 inputs.

Regardless of input type used, it is recommended that all in-

put wiring be done prior to applying power to the logic board.

Please verify that there are no shorts to AC Ground prior to

connection of input devices.

Regardless of input type, the following notes apply.

1. All low voltage wiring is Class 2 wiring.

2. All low voltage wiring must enter the cabinet into the Low

Voltage section of the enclosure. Low Voltage wiring can be

brought into the enclosure from the left side of the enclosure.

Failure to separate high voltage from low voltage wiring

may cause interference with logic board function.

3. All low voltage wiring must be run in separate conduit from

line-voltage wiring.

4. Test all low voltage wiring for shorts to AC ground before

connection to the relay panel.

5. When powering peripheral devices such as motion sen-

sors and photocells from the LiteKeeper

®

panel, there may

be a limitation on the number of sensors that can be sup-

ported. This is also true if digital switches are used with the

system. See the recommendations below or contact Cooper

Controls for further information.

6. It is recommended that power be removed from the logic

board when doing initial switch input wiring.

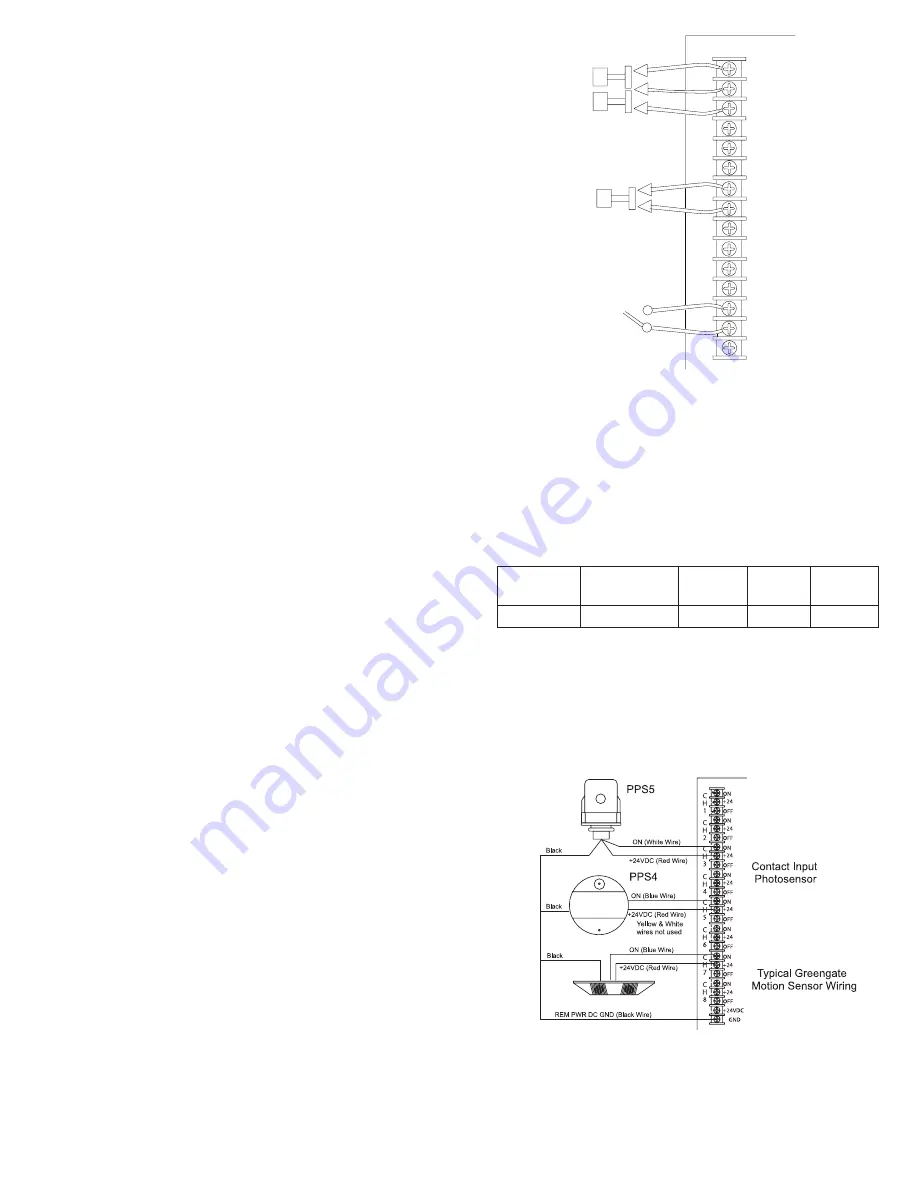

Contact Input Switch Wiring

This section describes the wiring for dry contact closure de-

vices. There are eight switch input wiring terminals on the left

side of the LiteKeeper-8

®

to allow for wiring of the dry contact

closure devices.

1. Use 18 AWG twisted, unshielded wire for all low voltage

dry contact closure device wiring.

2. Maximum length for dry contact closure device wiring is

1000 feet.

3. Please see wiring detail below for details on connections

of different devices to the LiteKeeper-8

®

system.

LiteKeeper-8

®

Low Voltage Switch Wiring

Contact Input Photosensor and Greengate Sensor Notes

It is possible to use a contact input photosensor and Greengate

Motion Sensors in conjunction with the lighting control system.

The LiteKeeper-8

®

is capable of powering a number of these

devices. Please refer to the chart below for details on how

many devices the transformer can support.

Please contact technical support if it is necessary to power

additional sensors beyond the numbers listed above. These

figures do not account for additional devices such as digital

switches being used. If using a combination of devices, please

contact technical support for exact limits on how the number

of devices the logic panel can power.

Photocell and Motion Sensor Wiring

ON

+24VDC

OFF

Momentary

Maintained

OFF

+24VDC

ON

ON

+24VDC

OFF

OFF

+24VDC

ON

ON

+24VDC

OFF

Toggle

C

H

1

C

H

2

C

H

3

C

H

4

C

H

5

40

16

20

20

Greengate

PIR Sensor

Greengate

Dual-Technology

Sensor

Greengate

Ultrasonic

Sensor

PPS-4

Indoor

Photosensor

4

PPS-5

Outdoor

Photosensor

Page 5