4

FIG. 4

Photocontrol (If Equipped)

1.

Using a flat blade screw driver, loosen the two

flathead screws to allow rotation of the receptacle.

2.

Insert screwdriver into center slot and rotate

receptacle until indicator arrow points north or

desired direction.

3.

Tighten screws.

4.

Insert the photoelectric control (or shorting cap) into

receptacle and twist into locked position.

Note

:

The photocontrol must contain a soft, resilient

gasket fastened to the bottom surface to assure a

proper weather seal between the control and the

receptacle.

Maintenance

Note

:

A regular maintenance schedule should be

followed to retain optimal light output and thermal

performance.

Optical lens cleaning should be performed with

a clean dry cloth to remove any dust or other

contaminants. Additional cleaning can be

performed with non-abrasive acrylic cleanser.

Remove any dirt, leaves or other foreign debris

from the housing and fi ns. Clean water may be

used to fl ush the fi ns.

Field Adjustable Drive Current (FADC) Option Only

(If Equipped) FIG. 5

1.

Connect grey driver wire to grey resistor pack wire.

2.

To change current to 525mA, connect purple

driver wire to purple resistor pack wire.

3.

To change current to 700mA, connect purple

driver wire to yellow resistor pack wire. (For Navion

with 1 Light Square, connect purple driver wire to

orange resistor pack wire).

4.

Position and secure all wires away from all other

electrical components (drivers, terminal blocks).

5.

Close access door and secure latches.

FIG. 5

Navion

TM

LED Area/Site Luminaire Installation Instructions

IMI-812 ADH140462

www.cooperlighting.com

Navion

TM

LED Area/Site Luminaire Installation Instructions

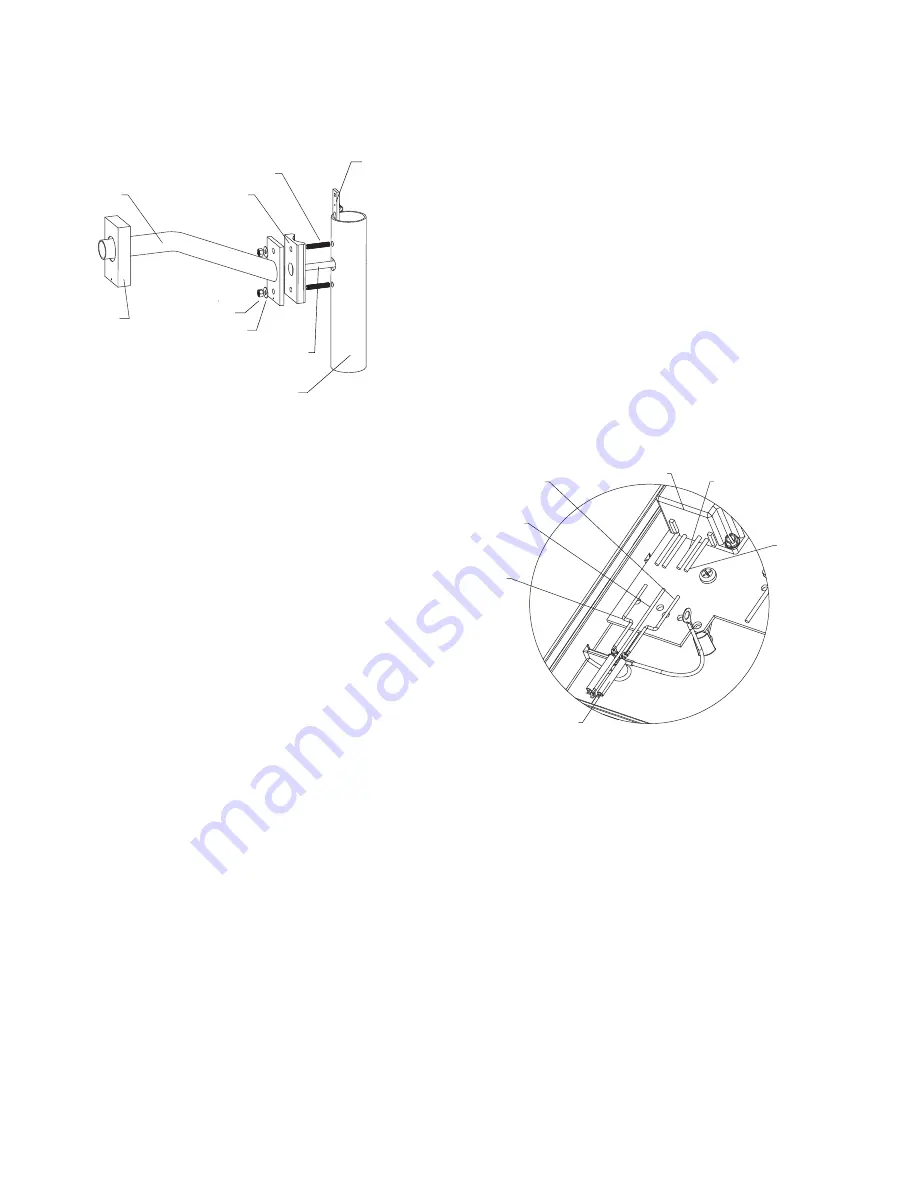

Arm

Adapter

Threaded Rods

Backup Plate

Cover Plate

Electrical Wires

Round Pole

Nuts

Washer

Yellow Resistor

Pack Wire

Grey Resistor

Pack Wire

Purple Resistor

Pack Wire

Resistor Pack

Driver

Grey Driver Wire

Purple

Driver

Wire