• After the log has been split, release both the control lever (11) and the power

button (7).

• The log pusher (1) returns to the starting position.

• Continue cutting logs using the same method.

Note:

The hydraulic oil and the pump may become very hot when splitting

very large and hard logs. This is why the machine is equipped with a

safety function to protect against overheating. The motor switches off

automatically when the maximum permissible temperature is exceeded.

Press the reset button (8) to switch the machine back on after it has

cooled down.

Removing jammed logs

• Release the power button and the control lever to allow the log pusher to

move backward.

Danger!

Risk of injury!

Never hammer or knock the jammed log or put your hands in too

close to the log. The hammering effect may rupture the motor block

or the hydraulic components.

• Fit a wedge (wood wedge) under the log. Re-activate the wood pusher.

• The wood wedge is pushed under the log.

• If the jammed log cannot be removed: Repeat the procedure using larger and

larger wedges.

Switching the machine off

• Unplug the power after you have finished using the machine.

• Tighten the air-bleed screw up again.

Maintenance

Danger!

Risk of injury!

Pull out the power plug before conducting any maintenance on

the machine. Wear safety goggles and (if necessary) a dust mask.

Maintenance overview

Prior to conducting any work.

Maintenance

Method

Check the power cable, hydraulic lines and hoses for any signs of damage.

Conduct a visual inspection and have the cable replaced by an electrician if necessary.

Check the oil level.

Re-filling the hydraulic oil – Page 6.

Change the hydraulic oil every 150 hours of use.

Draining/refilling the hydraulic oil – Page 6.

Sharpen the splitting wedge.

Sharpening the splitting wedge – Page 6.

Draining/refilling the hydraulic oil

Danger!

Danger of burning!

The hydraulic oil can become very hot when operating the

machine. Allow for the machine to cool down completely before

draining the hydraulic oil.

Note:

Always use a suitable oil tray.

Oil will damage the environment and must be disposed of

correctly. The hydraulic oil must be changed at regular intervals.

Draining the hydraulic oil

• Move the log pusher (1) back into the starting position.

• Allow the machine to cool down completely.

• Place a suitable tray underneath the machine.

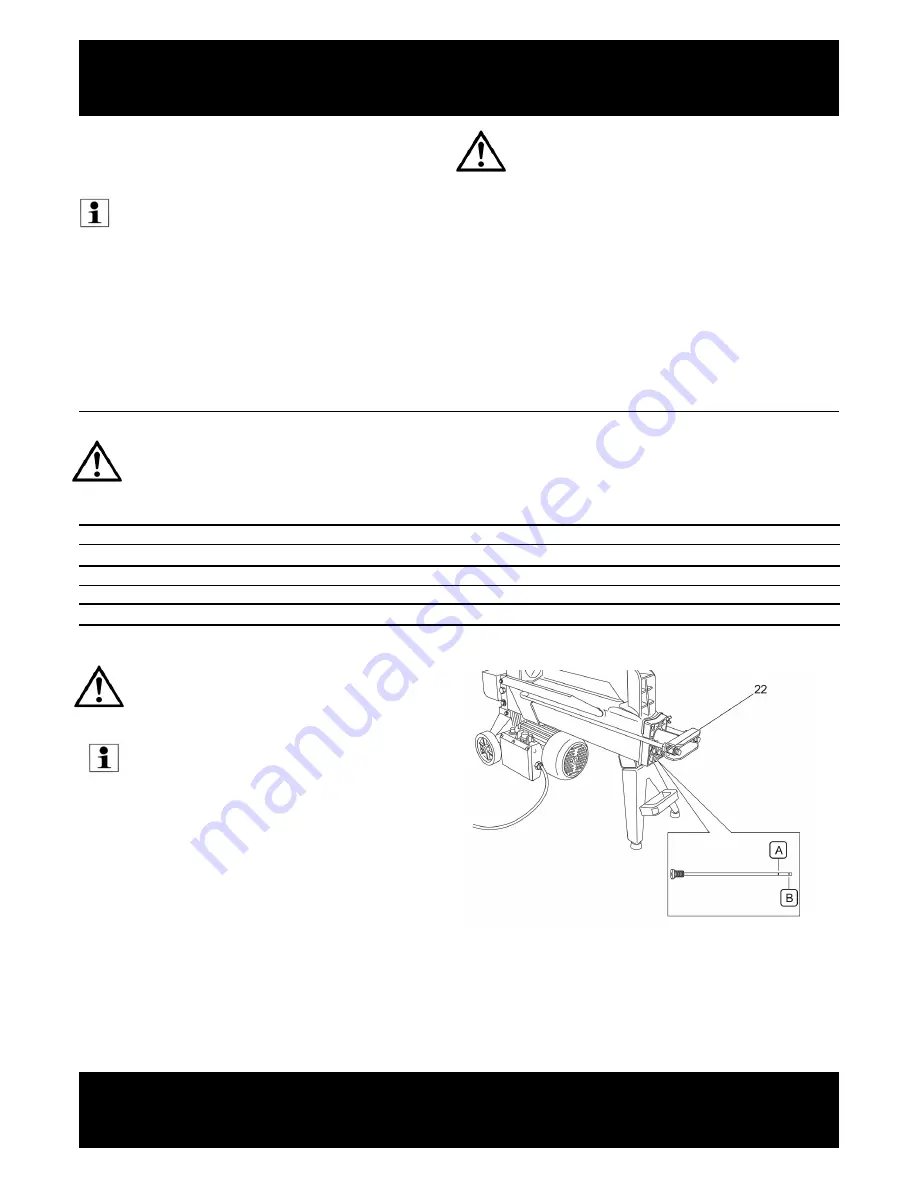

• Loosen the oil drainage screw (22) with an Allen key and unscrew it.

• Tilt the machine and allow the oil to drain.

Re-filling the hydraulic oil

• Set the machine up so that the oil refilling opening is pointing upwards.

• Fill the machine with fresh oil. Use the oil dipstick to check the level.

The oil must be at a level between the [A] and [B] markings. (Recommended

hydraulic oil – Page 8).

• Check the seal of the oil drainage screw (22) for damages. Replace a damaged

seal. Make sure the seal is positioned correctly.

• Tighten the oil drainage screw (22) up again.

Sharpening the splitting wedge

• Sharpen the splitting wedge with a fine file. Smooth any burrs or crushed areas

along the cutting edge.

6