- 6 -

D

ESCRIPTION

Before using the Straight Shaft Trimmer Attachment, familiarize yourself with all operating features and safety

requirements.

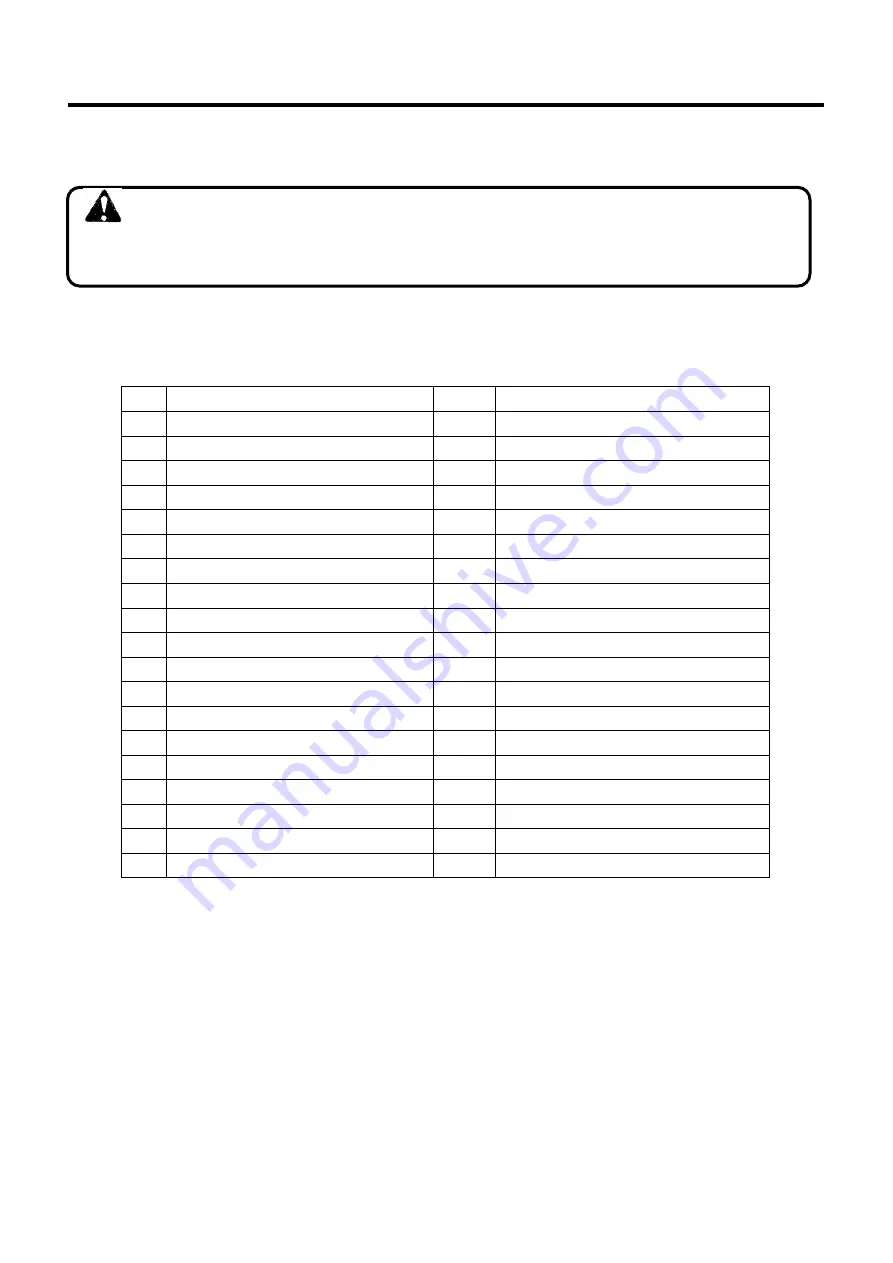

PART LIST OF THE EDGER ATTACHMENT

1

Blade Kit

21

Hex nut

2

Nut-lock

22

Hex screw

3

Washer-flanged (lower)

23

Flat- washer

4

Blade

24

Guide-curb

5

Washer-flanged

25

Wheel kit

6

Guard kit

26

Washer-flat

7

Screw-Hex

27

Wheel

8

Washer-lock

28

Nut-push

9

Flang

29

Gearhead & screw kit

10 Decal-warning label

30

Hexagon head screw

11 Logo label

31

Flat- washer

12 Guard W/ Hex screw

32

Cap head screw M6X30

13 Flap

33

Gear head Ass'y

14 Washer

34

Boom assembly

15 Nut-hex

35

Shaft flexible

16 Support arm assembly

36

Drives shaft housing ass'y

17 Support plate

37

Dustproof cover

18 Wheel mounting plate

38

Decal-warning label

19 Washer-flat

39

Hanger

20 Knob-adjusting W/ Nut-hex

40

Bar-removal & refitting the blade

WARNING

:

Do not allow familiarity with your tool to make you careless. Remember that a careless fraction of a second is

sufficient to inflict severe injury.