2C9-2

1-5-28

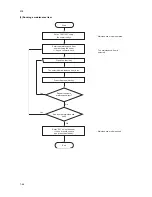

1-5-4 Electric problems

Problem

Causes

Check procedures/corrective measures

(1)

The machine does

not operate when the

power switch is

turned on.

No electricity at the power

outlet.

Measure the input voltage.

The power cord is not

plugged in properly.

Check the contact between the power plug and the outlet.

The front cover or left cover

is not closed completely.

Check the front cover and left cover.

Broken power cord.

Check for continuity. If none, replace the cord.

Defective power switch.

Check for continuity across the contacts. If none, replace the

power switch.

Blown fuse in the power

source PCB.

Check for continuity. If none, remove the cause of blowing and

replace the fuse.

Defective front or left cover

safety switch.

Check for continuity across the contacts of each switch. If none,

replace the switch.

Defective power source

PCB.

With AC present, check for 24 V DC at YC1-1 and 5 V DC at YC1-

7 on the power source PCB. If none, replace the power source

PCB.

(2)

The drive motor does

not operate

(C2000).

Poor contact in the drive

motor connector terminals.

Reinsert the connector. Also check for continuity within the con-

nector cable. If none, remedy or replace the cable.

Broken drive motor gear.

Check visually and replace the drive motor if necessary.

Defective drive motor.

Run maintenance item U030 and check if the drive motor oper-

ates when YC7-5 on the engine PCB goes low. If not, replace the

drive motor.

Defective engine PCB.

Run maintenance item U030 and check if YC7-5 on the engine

PCB goes low. If not, replace the engine PCB.

(3)

The registration

motor does not oper-

ate.

Poor contact in the registra-

tion motor connector termi-

nals.

Reinsert the connector. Also check for continuity within the con-

nector cable. If none, remedy or replace the cable.

Broken registration motor

gear.

Check visually and replace the registration motor if necessary.

Defective registration

motor.

Run maintenance item U030 and check if the registration motor

operates when YC2-1,2,4,5 on the registration motor PCB goes

low. If not, replace the registration motor.

Defective engine PCB.

Run maintenance item U030 and check if YC4-4 on the engine

PCB goes low. If not, replace the engine PCB.

(4)

The exit motor does

not operate.

Poor contact in the exit

motor connector terminals.

Reinsert the connector. Also check for continuity within the con-

nector cable. If none, remedy or replace the cable.

Broken exit motor gear.

Check visually and replace the exit motor if necessary.

Defective exit motor.

Run maintenance item U030 and check if the exit motor operates

when YC14-1,2,3,4 on the engine PCB go low. If not, replace the

exit motor.

Defective engine PCB.

Run maintenance item U030 and check if YC14-1,2,3,4 on the

engine PCB go low. If not, replace the engine PCB.

Summary of Contents for CS-1620

Page 1: ...SERVICE MANUAL Published in June 05 2C970946 Revision 6 CS 1620 2020...

Page 4: ...This page is intentionally left blank...

Page 10: ...This page is intentionally left blank...

Page 48: ...2C9 4 1 4 7 This page is intentionally left blank...

Page 61: ...2C9 4 1 4 18 This page is intentionally left blank...

Page 73: ...2C9 4 1 4 28 This page is intentionally left blank...

Page 84: ...2C9 4 1 4 37 This page is intentionally left blank...

Page 94: ...2C9 4 1 4 45 This page is intentionally left blank...

Page 147: ...2C9 4 1 6 16 This page is intentionally left blank...

Page 173: ...2C9 6 0 1 6 40 This page is intentionally left blank...

Page 235: ......