7

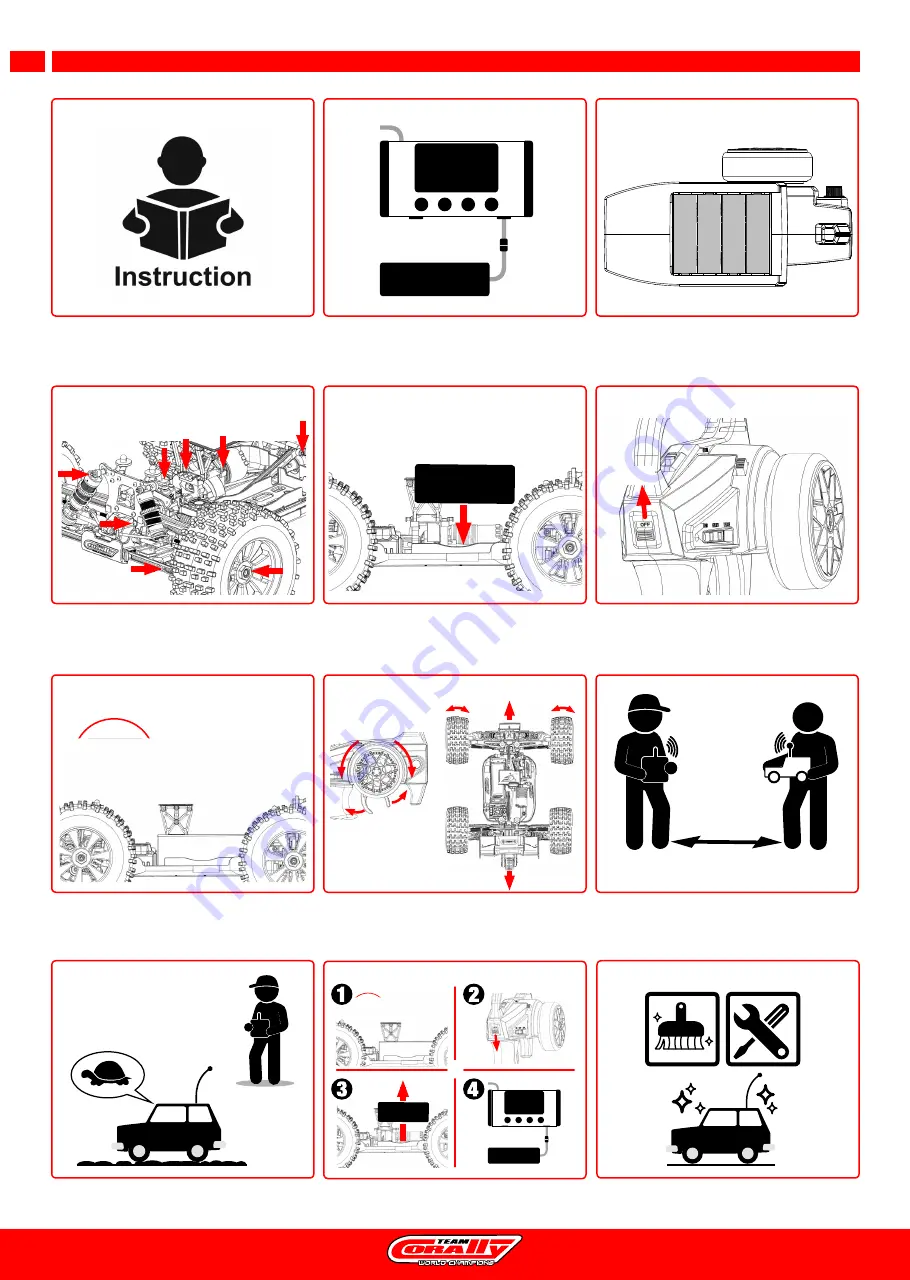

QUICK START GUIDE

ON

OFF

1.5V - AA BA

TTER

Y

INSTALL 4x AA BATTERY

TURN ON THE TRANSMITTER (Always First)

READ THE INSTRUCTIONS

MAKE SURE THAT ALL SCREWS AND NUTS ARE

TIGHTENED PROPERLY.

CHARGE THE BATTERY

INSTALL THE BATTERY

WHEN FINISHING

CHECK THE FUNCTIONS

CHECK THE RADIO SYSTEM RANGE

Move away from the max. distance you will drive the vehicle.

Check that the vehicle responds properly to the controls.

If not, reduce the distance or change the driving location.

DRIVE SLOWLY TO BEGIN

1.5V - AA BA

TTER

Y

1.5V - AA BA

TTER

Y

1.5V - AA BA

TTER

Y

CHARGER

BATTERY

BATTERY

BATTERY

ON

OFF

1. CONNECT THE BATTERY TO THE ESC

2. SWITCH ON THE ESC

CLEAN AND MAINTAIN YOUR VEHICLE

CHARGER

BATTERY

CHARGE THE BATTERY