Page 34

AFTER EACH RIDE

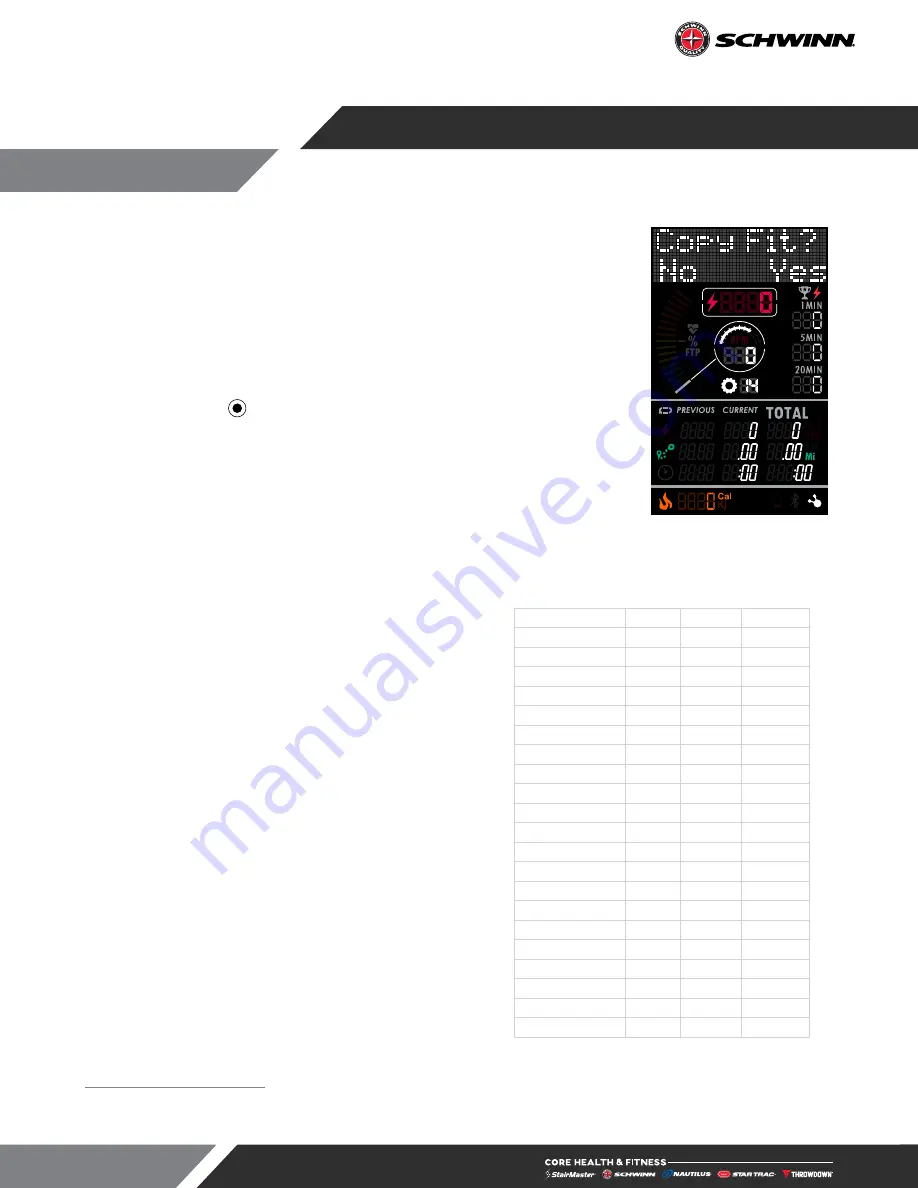

Fig. 24

USB Retrieval

Upload data from the console to your USB drive

The ride data file is a great tool for people to track their rides and see their

progress. After ride is complete you may save ride data from the console to a USB

stick.

1.

Insert USB stick into console port.

2.

Message center will display

COPY FIT?

3.

Tap the right

button to begin the upload.

4.

Console will save the ride file as

SCHWINNZ1.CSV

4

5.

Message center will return to SUMMARY when upload is complete.

6.

Once the data upload is complete, the stick may be removed.

The ride data file will display the following

5

:

• Summary data for the entire ride

• Summary data for each stage

• Total ride data recorded every second

RIDE SUMMARY

Total Time

32.9

Minutes

Total Distance

9.14

MI

AVG Power

98

MAX Power

210

AVG RPM

104

MAX RPM

112

AVG HR

138

MAX HR

155

CAL

226

RIDE DATA

Power

RPM

HR

DISTANCE

29

90

101

0

48

89

101

0

48

89

101

0.01

48

89

101

0.01

48

89

102

0.01

48

89

101

0.02

48

89

101

0.02

48

89

101

0.02

48

89

101

0.03

Table 1

Ride Summary Example

4

If a ride file exists on the USB stick with the filename SCHWINNZ1.CSV the console will save the file with the next number: SCHWINNZ2.CSV.

The console will increment numbers as needed as long as there is space on the USB stick.

5

The console continues to record data aftter the ride is complete, however lines with no recorded activity are ignored in the summary calculations.