English

Operating instructions

21

Cause:

The lid is not correctly closed or tends to open;

The product lifts the lid due to an excessive quantity or an excessive volume increase. Use a

smaller amount of mixture or more suitable ingredients.

The lid’s magnet is damaged. Call the Assistance Service.

Cause:

The chute with protection flap is not correctly in place.

The magnet or the chute’s magnetic contact is damaged. Please call Assistance Service.

THE MAGNETS AND THEIR CONTACTS ARE IMPORTANT SAFETY DEVICES!

Cause:

The refrigerator’s safety pressure switch comes on. Check the machine’s air/condensing

water supply. See also par. Malfunctions:

“The refrigeration is insufficient…”

The compressor’s back up relay switches off, following excessive stress (repeated starts,

high pressure, overheating). Stop the device, wait a feu minutes and start again. If the incon-

venient shall repeat or frequently repeat, call the assistance service.

The Beater ’s back up relay switches off, following overuse or mechanical overload. Check

that the eventual product in the cylinder is not excessively dense and that there are no other

causes of mechanical stress. Stop the device, wait a feu minutes and try again. If the incon-

venient should not be eliminated, or should frequently repeat, call the assistance service.

Note:

it may be necessary to wait up to 30 minutes for the thermal protections to cool down.

With the Main Breaker on 1 the ON/OFF indicator light [Z1] TURNS ON, but the device does not work.

Cause:

Break down of inside parts or at the electronic controls. Call the Assistance Service.

THE DEVICE CAUSES REPEATED RELEASES OF THE MAINS ELECTRICAL PROTEC-

TIONS OR THE INTERRUPTION OF MAINS FUSES.

Cause:

The capacity of the electrical plant is not sufficient to feed the device.

The electrical characteristics of protections and fuses are not adequate.

Inside breakdown of the device. Call the assistance service.

THE REFRIGERATION IS INSUFFICIENT OR DISACTIVATES IN AN ANOMALOUS WAY.

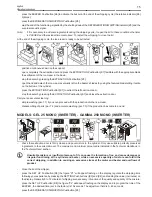

AIR CONDENSATION devices

Cause:

Obstacles are placed at the air conditioning’s opening, at a distance lower than that de-

scribed. Restore the minimal distance reported in the Technical Handbook.

The room temperature is too high and condensation is inadequate.

The air condensator is dirty. Request the cleaning at the Assistance Service.

The condensator ’s fan is broken. Call the Assistance Service.

Break down of the refrigerating system or at the electrical controls. Call the Assistance Serv-

ice.

WATER CONDENSATION devices:

Cause:

The flow of condensation water is interrupted or insufficient.

The water tubes present constrictions. Avoid constrictions.

The water condensation faucet/s are partially or totally closed.

The static pressure valve must be newly regulated, otherwise it is broken. Call the Assistance

Service.

Summary of Contents for GAMMA 250 MONO

Page 2: ...English Ice cream freezer 2...