XD601-D2 Piezo Nanopositioning Stage User Manual

6

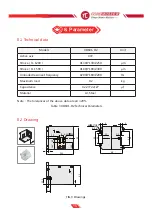

The identification of the labels on the wires of XD601-D2 is as follows:

Table1. XD601-D2 Wire Identification and Motion Direction

4. Operating environment

A clean, dustfree and non-corrosive environment

Operating temperature : -20~80℃

Relative humidity : <60%

Recommended voltage range is 0~120V for long-term use and lifetime

5. Installation and operation

Safety check should be carried out before installation, such as whether the connection wire

is damaged or broken, whether the drive power supply is grounded, etc.

5.1 Installation and Precautions

1、Make sure the mounting surface is flat.

2、Use M3 screws to mount the XD601-D2 and tighten.

3、Mount a load and tighten it properly to achieve high positioning accuracy.

4、Connect XD601-D2’s connector to the corresponding interface of the controller

according to the identification on the leads.

Model

Motion direction

Function

Label

XD601-D2

Y

PZT Drive

CH1

Senser output

1

X

PZT Drive

CH2

Senser output

2

Z

PZT Drive

CH3

Senser output

3