72

Operator’s manual

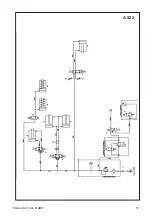

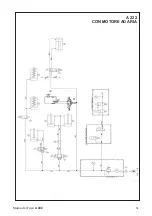

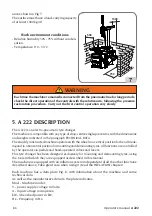

A 222

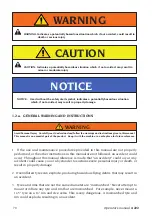

tripped over or pulled.

11. Risk of Eye Injury. Flying debris, dirt and fluids may be discharged

during bead seating and the inflation process. Remove any debris

from the tyre tread and wheel surfaces. Wear OSHA, CE or other

approved safety glasses during mount and demount procedures.

12. Always inspect the machine carefully before using it. Missing, broken, or worn equip-

ment (including warning stickers) must be repaired or replaced prior to operation.

13. Never leave nuts, bolts, tools or other equipment on the machine. They may become

trapped between moving parts and cause a malfunction.

14. NEVER install or inflate tyres that are cut, damaged, rotten or worn. NEVER install a

tyre on a cracked, bent, rusted, worn, deformed or damaged rim.

15. If a tyre becomes damaged during the mounting process, do not attempt to finish

mounting. Remove from the service area and properly mark the tyre as damaged.

16. To inflate tyres, use short bursts while carefully monitoring the pressure, tyre, rim and

bead. NEVER exceed the tyre manufacturer’s pressure limits.

17. This equipment has internal arcing or sparking parts which should not be exposed

to flammable vapours (gasoline, paint thinners, solvents, etc.). This machine should not

be located in a recessed area or below floor level.

18. Never operate the machine if you are under the effects of alcohol, medications and/

or drugs. If you are taking prescription or over the counter medication, you must consult

a medical professional regarding any side effects of the medication

that could hinder your ability to operate the machine safely.

19. Always use OSHA, CE or other approved and mandated Personal

Protective Equipment (PPE) during use of the machine. See your

supervisor for more instructions.

20. Remove jewellery, watches, loose clothing, ties and restrain long

hair before using the machine.

21. Wear non-slip safety footwear when operating the tyre changer.

22. Wear proper back support and employ a proper lifting technique

when placing, moving, lifting or removing wheels from the tyre changer.

23. This machine may only be used, maintained or repaired by properly

trained employees of your company. Repairs should only be performed

by qualified personnel. Your CORGHI service representative is the

most qualified person. The employer is responsible for determining

if an employee is qualified to safely make any repairs to the machine

should repair be attempted by users.

Summary of Contents for A 222

Page 59: ...Manuale d uso A 222 59 A 222 ...

Page 60: ...60 Manuale d uso A 222 A 222 VERSIONE TI ...

Page 61: ...Manuale d uso A 222 61 A 222 CON MOTORE AD ARIA ...

Page 62: ...62 Manuale d uso A 222 A 222 VERSIONE TI CON MOTORE AD ARIA ...

Page 63: ...Note 63 ...

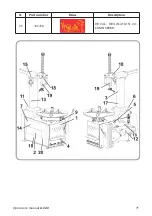

Page 121: ...Operator s manual A 222 121 A 222 ...

Page 122: ...122 Operator s manual A 222 A 222 TI VERSION ...

Page 123: ...Operator s manual A 222 123 A 222 WITH AIR MOTOR ...

Page 124: ...124 Operator s manual A 222 A 222 TI VERSION WITH AIR MOTOR ...

Page 125: ... 125 ...

Page 183: ...Utilisation et entretien A 222 183 A 222 ...

Page 184: ...184 Utilisation et entretien A 222 A 222 VERSION TI ...

Page 185: ...Utilisation et entretien A 222 185 A 222 MOTEUR PNEUMATIQUE ...

Page 186: ...186 Utilisation et entretien A 222 A 222 VERSION TI MOTEUR PNEUMATIQUE ...

Page 187: ...Note 187 ...

Page 245: ...Betriebs und Wartungsanleitung A 222 245 A 222 ...

Page 246: ...246 Betriebs und Wartungsanleitung A 222 A 222 VERSION TI ...

Page 247: ...Betriebs und Wartungsanleitung A 222 247 A 222 DRUCKLUFTMOTOR ...

Page 248: ...248 Betriebs und Wartungsanleitung A 222 A 222 VERSION TI DRUCKLUFTMOTOR ...

Page 249: ...Hinweise 249 ...

Page 307: ...Uso y mantenimiento A 222 307 A 222 ...

Page 308: ...308 Uso y mantenimiento A 222 A 222 VERSIÓN TI ...

Page 309: ...Uso y mantenimiento A 222 309 A 222 MOTOR NEUMÁTICO ...

Page 310: ...310 Uso y mantenimiento A 222 A 222 VERSIÓN TI MOTOR NEUMÁTICO ...

Page 311: ...Notas 311 ...