Technical Support Manual – 05/2015 Rel. 0

Page 9

5. MACHINE CALIBRATION

The machine must be calibrated in order to run. The machine calibration procedure saves the mechanical and electrical parameters

of every machine in an internal permanent memory (EEPROM). This way, the machine will provide better balancing results.

5.1 When to carry out machine calibration

Table T5.1 lists all the cases in which the machine must be calibrated. The machine must be calibrated each time the conditions

described below occur.

Table T5.1: Conditions that require machine calibration

Condition

Status

Who must perform it

When the machine is manufactured

Mandatory

Cormach srl

When the machine is installed at the site of the end customer

Mandatory

SERVICE technical personnel

When the CPU-C1 electronic control unit is updated or replaced

Mandatory

SERVICE technical personnel

When a mechanical part relative to the pick-up signals is replaced (pick-up,

springs, shaft unit)

Mandatory

SERVICE technical personnel

When the compression spring adjustment is altered

Mandatory

SERVICE technical personnel

When the ENCODER disc is replaced

Mandatory

SERVICE technical personnel

When the machine does not provide correct balancing measurements

Recommended End user and/or SERVICE

Technical Support

When you have relevant and constant room temperature and humidity

variations (e.g. seasonal changes)

Recommended End user and/or SERVICE

Technical Support

A non-calibrated machine provides balancing results equal to 0 grams (0.0 ounce).

5.2 How to calibrate the machine for CAR/SUV wheel type

•

Diameter: 15”.

•

Width: 6”.

•

Distance: as close as possible to 100 mm.

It is also possible to use a wheel with dimensions similar to those indicated, provided that the difference is not excessive. Aluminium

wheels cannot be used to calibrate the machine.

To calibrate the machine, proceed as follows:

1.

Switch the machine on;

2.

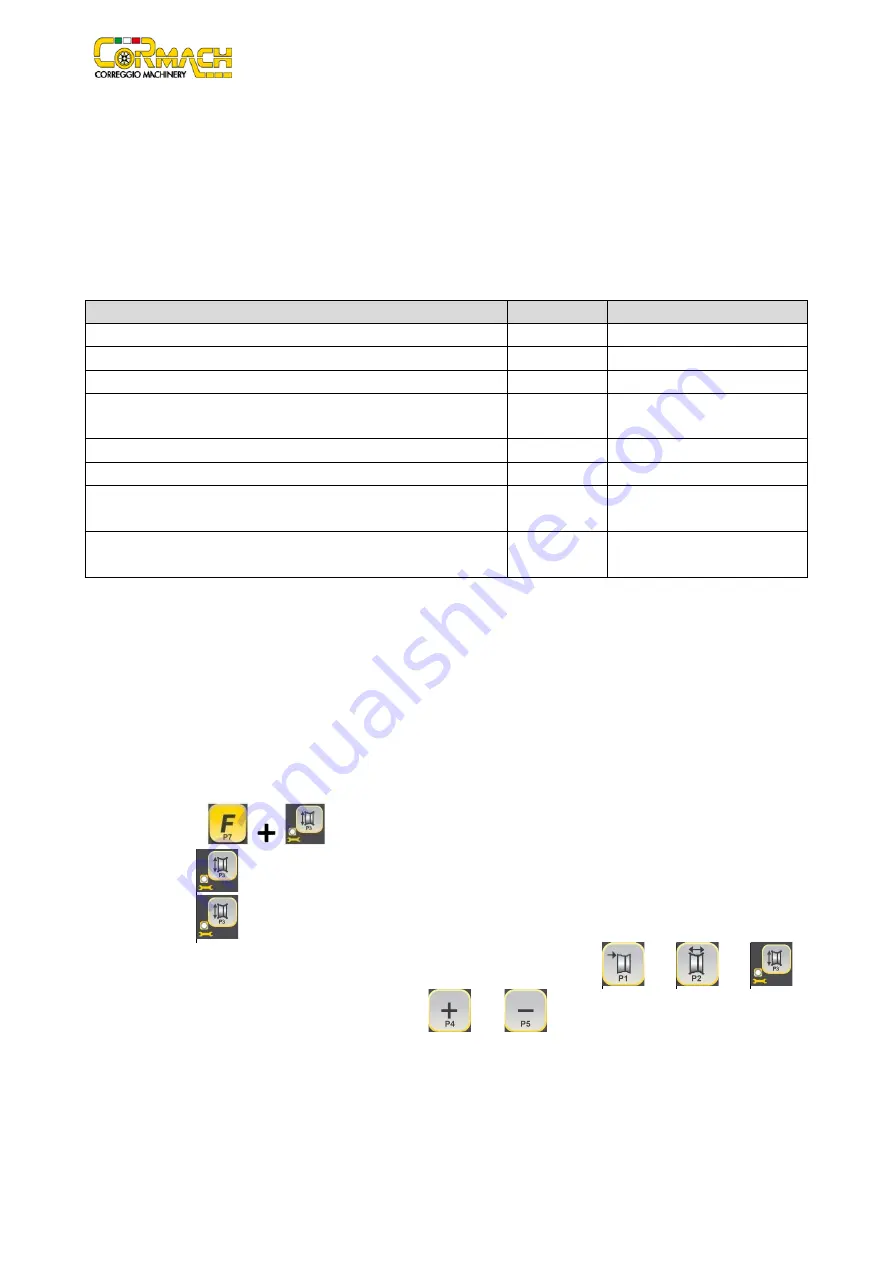

Press [F+P3]

. The display will show

SER SER

, which indicates the activation of the SERVICE mode;

3.

Press [P3]

. The display shows

CAL CAR

(machine calibration for auto-vehicles and off-road vehicles);

4.

Press [P3]

. The display will show

CAL 1

;

5.

Place the wheel on the shaft and block it. Enter the wheel dimensions with keys [P1]

, [P2]

, [P3]

to

select the dimensions to be modified and keys [P4]

, [P5]

to change the values. If the dimensions of the

wheel have been introduced before entering the calibration procedure, this step can be skipped;

6.

Manually run a launch by acting on the locking ring with knobs;

7.

Once the launch is completed, manually rotate the wheel until value 50 is seen on the left display. Apply the 50 g weight at

the 12 o'clock position on the internal side of the wheel;

8.

Manually run a launch by acting on the locking ring with knobs;

9.

Remove the 50 g weight applied on the internal side;

Summary of Contents for MEC 1

Page 1: ...EQUILIBRATRICI MEC 1 MEC 1 BAT TECHNICAL SUPPORT MANUAL UK...

Page 2: ......

Page 18: ......