Use and Maintenance Manual – 08/2018 Rel. 4

Page 44

19.5 SWI wheel stop procedure on the positions of imbalance

Machines equipped with the electromagnetic clamping brake are capable of automatically stopping the wheel at the first imbalance

angular position that is reached during rotation. This allows the operator to have the wheel in position ready for the application of

the balancing weight thus increasing work and productivity speeds.

The procedure is referred to with the short English acronym SWI (Stop the Wheel on Imbalance). Within this manual, this acronym

will be used to refer to the wheel stop procedure on the positions of imbalance. The SWI procedure has three different operating

modes indicated in table T19.2.

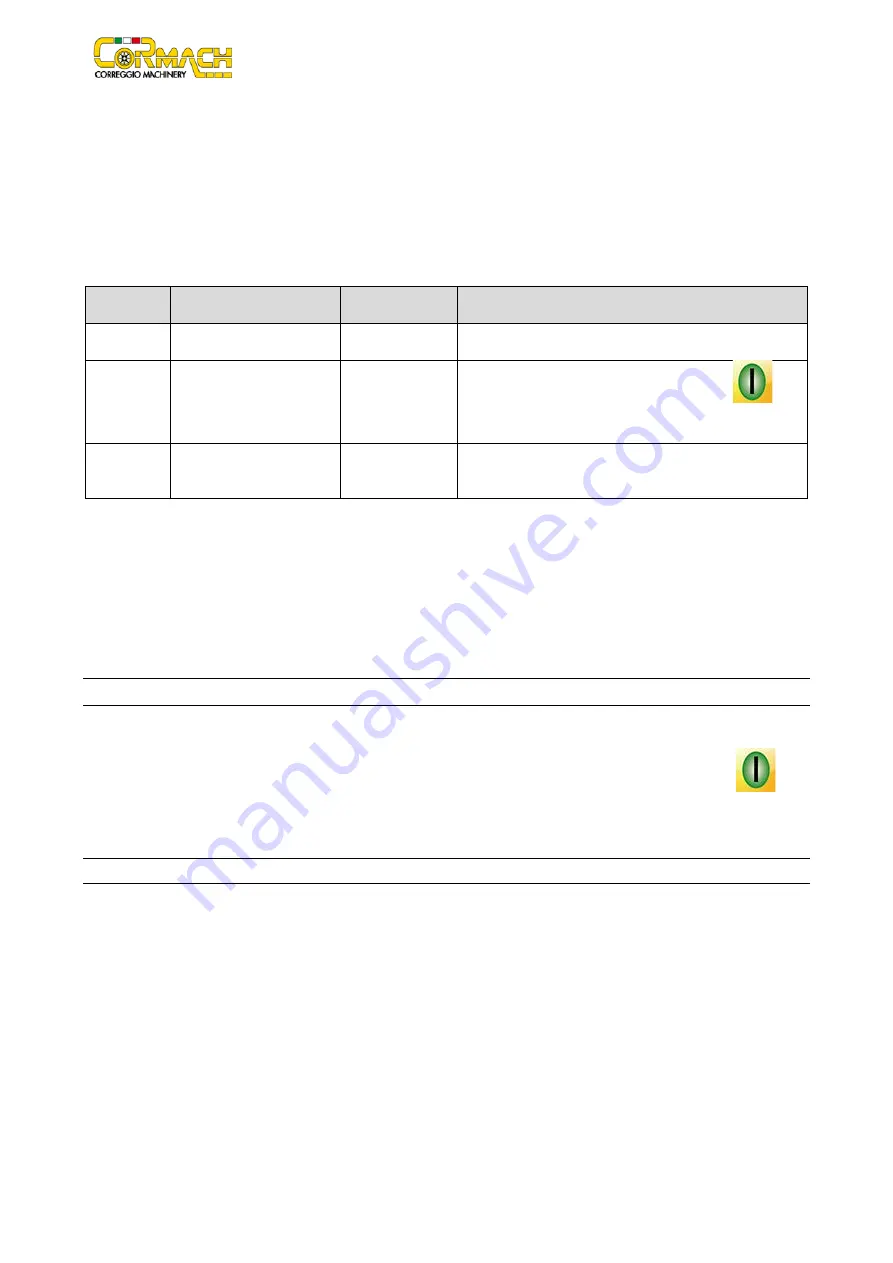

Table T19.2: Types of SWI procedures available

SWI mode

When it is or when it can

be run

Who can run the

SWI procedure

Notes

Automatic

At the end of every launch.

Machine

This is performed only if there is at least one imbalance value

on the wheel. Otherwise, conventional braking will occur.

Low speed

At the end of the launch,

when the wheel is

stationary and the wheel

guard is raised.

Operator

The procedure is started by pressing on icon

: the

wheel starts at low speed until it reaches the first imbalance

angular position.

Manual

At the end of the launch by

manually rotating the wheel

with wheel guard raised.

Operator

At each passage of the wheel in an angular position of

imbalance, the electromagnetic clamping brake will be

enabled for 30 seconds.

The three SWI modes have functions that are slightly different one from the other although, in all modes, the ultimate goal is to block

the wheel at an angular position of imbalance and make operator’s tasks quicker.

19.5.1 Automatic SWI procedure

During the automatic SWI procedure, the machine will measure rotational speed during braking at completion of the launch and,

when this reaches a predetermined value, it will release the brake allowing the wheel to spin freely by inertia. When the speed is low

enough, the machine will wait until the wheel passes through one of the angular positions of imbalance, therefore, it will enable the

electromagnetic clamping brake.

Note: for operator safety purposes, the SWI procedure will not be run when the MOTO Wheel Type is enabled.

19.5.2 SWI procedure at low speed

In the low speed SWI procedure, the wheel has already run the launch and is stationary. If the operator presses on icon

with

the wheel guard raised, the machine will apply slight acceleration to the wheel and then let it spin by inertia. When the speed is low

enough, the machine will wait until the wheel passes through one of the angular positions of imbalance, therefore, it will enable the

electromagnetic clamping brake.

Note: for operator safety purposes, the SWI procedure will not be run when the MOTO Wheel Type is enabled.

19.5.3 Manual SWI procedure

In this mode, the SWI procedure is activated by manual rotation of the wheel if the wheel guard is raised. When the wheel passes

through an angular position of imbalance, the machine will enable the electromagnetic clamping brake.

Angular positioning accuracy depends on many factors. The main ones being: wheel dimensions and weight, electromagnetic brake

adjustment, temperature, belt tension. In all cases, consider the following:

•

If the electromagnetic clamping brake is disabled, the SWI procedure will not be run in any of three modes;

•

If rotation speed decreases abruptly due to wheel inertia during the automatic SWI procedure or the low speed SWI (e.g.

due to excessive friction with rotating mechanical parts) the machine applies a little extra acceleration to the wheel itself

in order to reach the first angular position of imbalance. If, despite this, the wheel does not reach this position, the SWI

procedure is aborted after 5 seconds and the machine displays the error code

ERR 042

;

•

When using the manual SWI procedure, precision also depends on the speed that the operator turns the wheel at:

excessively high or low speeds reduce precision.