CH1500, CH2000 & CH3000 Chiller Operator’s & Installation Manual

© 2010-2014, Cornelius Inc.

- 3 -

Publication Number: 621055837OPR

GENERAL INFORMATION

I

NTRODUCTION

Cornelius CH Series, Refrigerated Recirculating Water Chillers are designed to provide a continuous flow of clean

cooling water at a constant temperature and to handle a variety of closed loop and tank cooling applications.

The CH Series consists of a refrigeration system with associated operating controls housed in a sturdy sheet metal

cabinet. A standard pump and reservoir package provides a complete self-contained water cooling and circulating

system.

CH Series Chillers are designed to operate in a clean laboratory or industrial environment where ambient

temperatures range from 50

o

F to 100

o

F. Once properly installed, CH Series Chillers run virtually maintenance free

and provide a constant supply of cooling liquid to the application.

Specifications

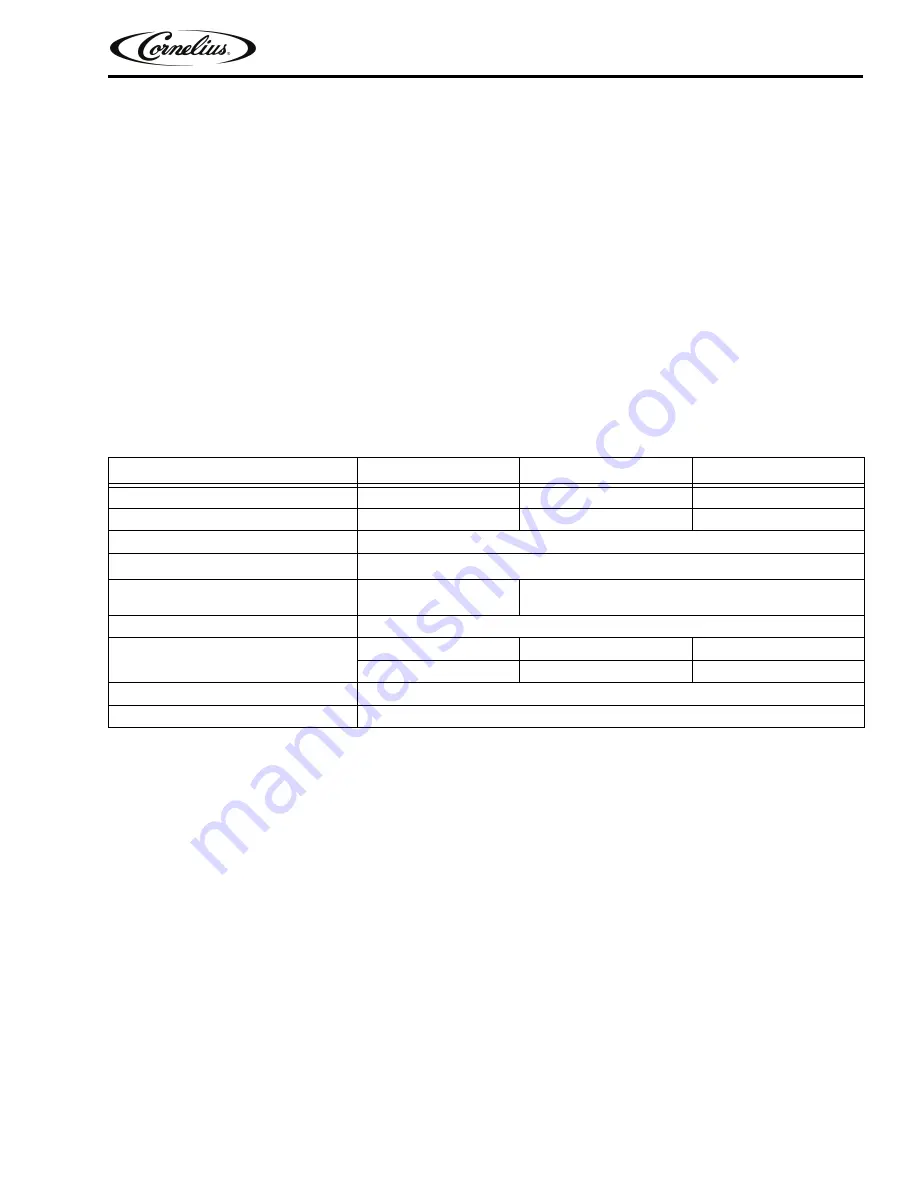

The CH Series specifications are shown in Table 1.

Specification Notes

1.

The figures for power and cooling capacity are listed for air-cooled units with a circulation temperature of

68° F and ambient temperature of 80° F and standard pump.

2.

Cooling capacity will be affected as follows: Derate 17% for 50 Hz operation. Derate 1% for each degree

Fahrenheit drop in recirculating temperature. Derate 0.5% for each degree Far en he it increase in ambient

temperature.

3.

The operating water temperature range for water is 50°F (10

o

C) to 100°F (38°F). If uses of other fluids or

temperatures are required, the Technical Service Department must be contacted so the appropriate

ranges can be set.

4.

All CH Series Chillers are thoroughly tested before leaving the factory to ensure that each unit meets these

specifications prior to shipment.

Table 1.

Model

CH1500

CH2000

CH3000

Cooling capacity, Watts/BTU/hr

5861/20000

7033/24000

9964/34000

Compressor

1.5 HP

2 HP

3 HP

Condenser

Air Cooled

Temperature Controller

Digital Display 40

o

-100

o

F

Pump

1CS (10 GPM @ 35

PSI)

2CS (12 GPM @ 50 PSI)

Reservoir (Capacity)

10 Gallons

Voltage (Full Load Amps)

CH1502A 230/60/3 (10)

CH2002A 230/60/3 (14)

CH3002A 230/60/3 (18)

CH1503A 460/60/3 (5)

CH2003A 460/60/3 (7)

CH3003A 460/60/3 (9)

Dimensions W x D x H (inches)

28 x 28 x 41

Inlet/Outlet Fitting Size

3/4-inch