6

Dual SGHN4 Series

REVISION # 0000

DATE: 05/29/2018

Disconnect power at the fuse box before proceeding with any wiring.

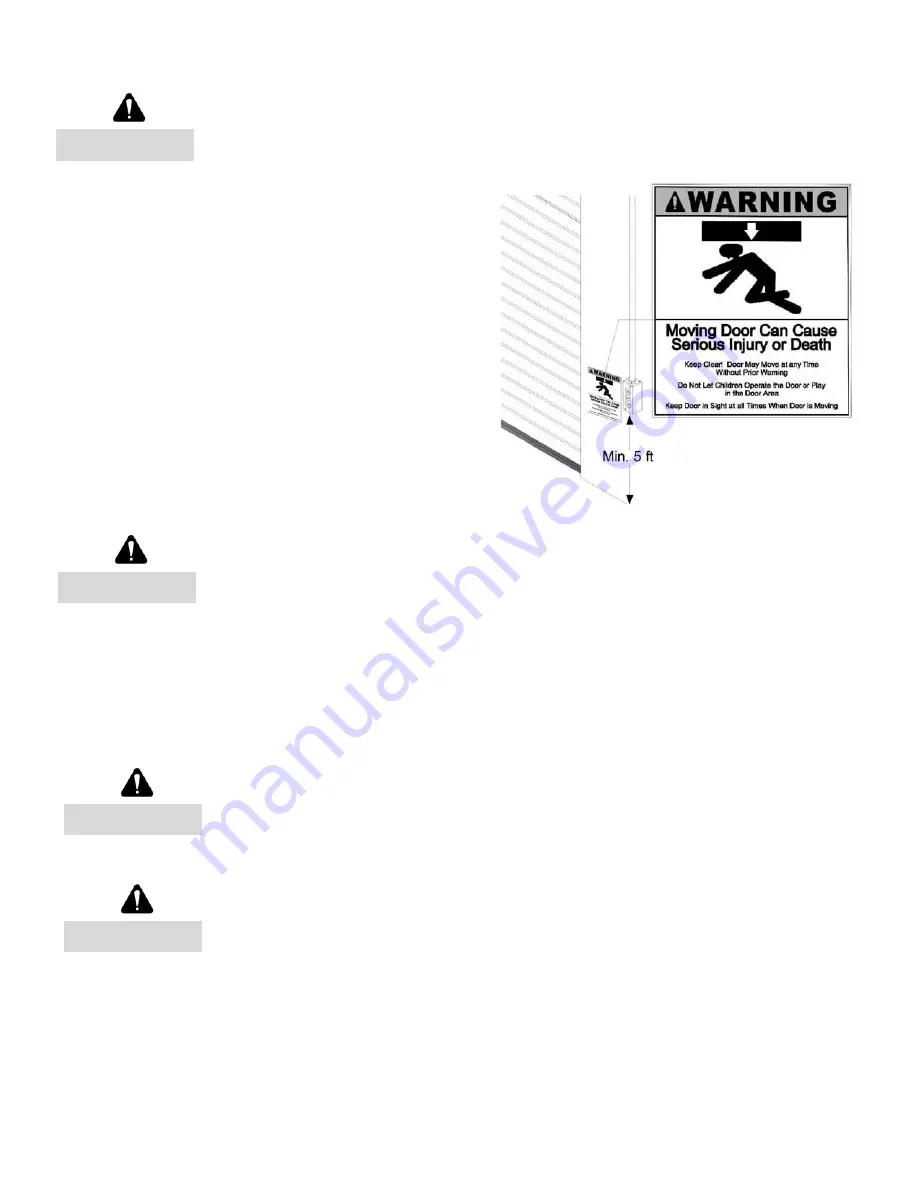

2. Locate the control station where the user can

clearly see the operation of the door. Mount the

enclosed placard adjacent or near the door.

Controls shall be far enough from the door, or positioned such that the user

is prevented from coming in contact with door while operating the controls.

3. Do not run control wiring in the same conduit as power wiring.

4. Any wire connected to the control panel must be protected by conduit or other means to ensure the

safety and permanency of the wiring.

Do not use radio controls with your operator unless some type of

entrapment protection device has been installed. Failure to do so may result

in serious injury or death to person(s) trapped beneath the door.

Changing from left hand to right hand or vice versa could result in change

of control wiring. Consult factory for details.

5. After installation, be sure that the operator, controls, and sensing edge or other entrapment

protection devices have been tested and function properly.

WARNING

WARNING

WARNING

WARNING