STANDARD RECOMMENDED PROCEDURE 009-221 | ISSUE 8 | AUgUST 2015 | PAgE 3 OF 10

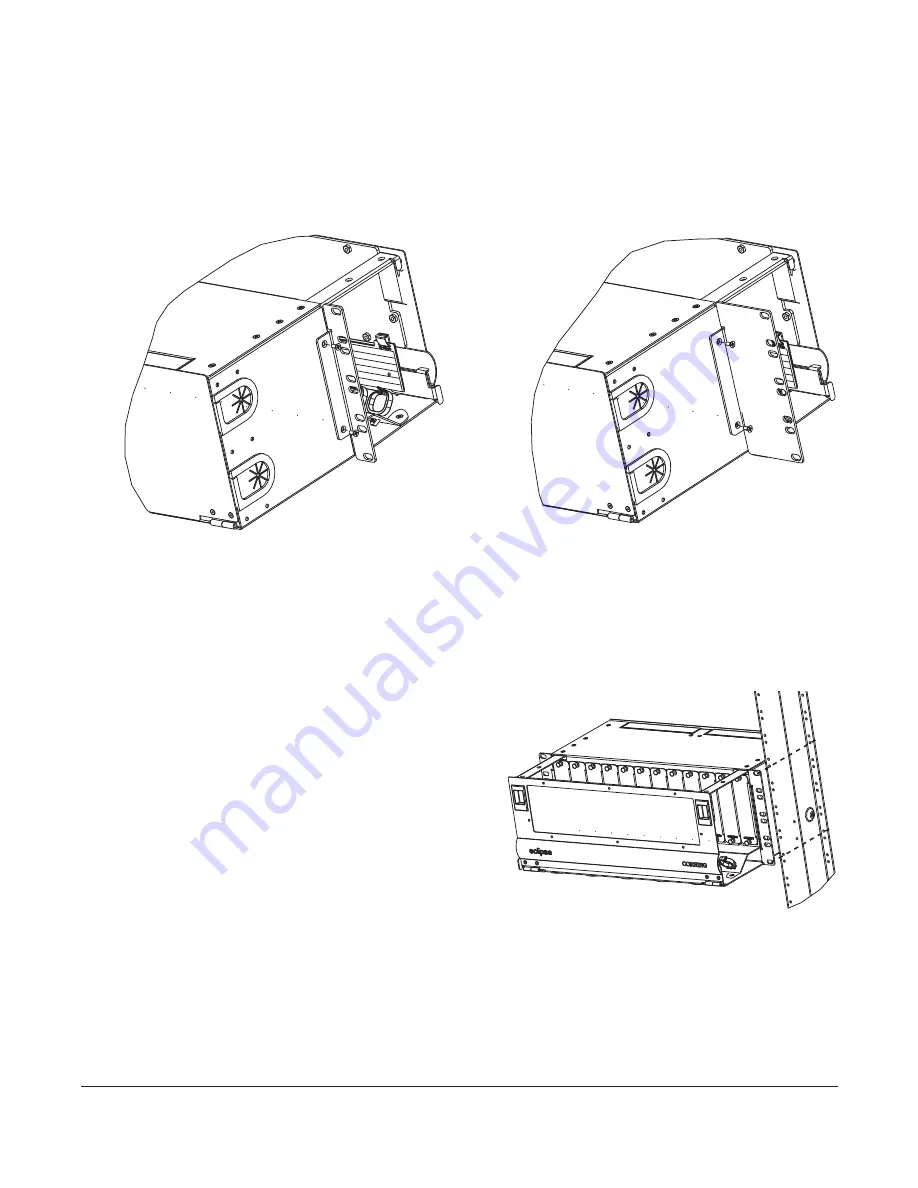

Step 1:

To install the housing from the front of the equipment rack, attach the appropriate

mounting brackets (Figure 3) to the supporting flange on the housing using the 6-32

screws provided.

Step 2:

Remove paint from the mounting bracket with sandpaper at one of the mounting hole

locations to provide metal-to-metal contact for grounding the housing.

Step 3:

Mount the housing to the equipment rack using thread-cutting screws.

NOTE:

The mounting bracket must have metal-to-metal contact providing an electrical path to properly

ground the housing.

19-inch

rack-mount

bracket

23-inch

rack-mount

bracket

Figure 3

5.2 Stubbed Housing

Factory-stubbed units are available with a specific length of preconnectorized cable installed

and strain-relieved in the unit. Install stubbed

housings from the rear of the equipment rack.

Step 1:

Slide the housing into the equipment

rack from the rear before attaching

the mounting brackets.

Step 2:

While supporting the unit, install the

appropriate mounting brackets using

the 6-32 screws provided as shown in

Figure 3.

Step 3:

Fasten the brackets to the equipment

rack using the screws provided. (If

mounting to an Eclipse frame, use the

12-24 screws provided.)

IMPORTANT:

Align the top mounting hole of the housing so that the next hole above is 1/2 inch higher

(Figure 4). Doing otherwise will result in the misalignment of the lower mounting holes.

KPA-2190

KPA-2191

KPA-2192

Figure 4