Page 11

SRP-003-545 • Issue 4 • July 2004

12.3

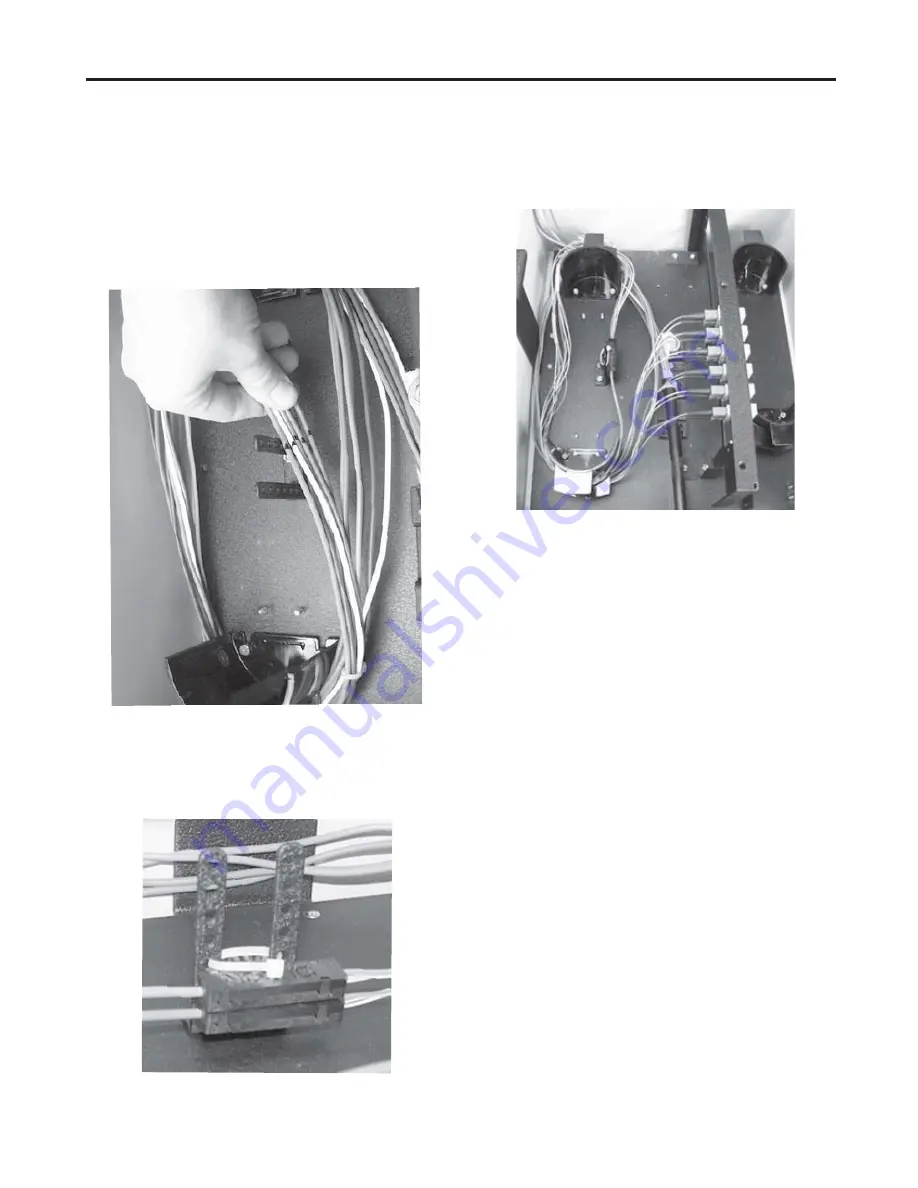

Route the buffer tubes around the radius

guides three times in a counterclockwise

direction. Mark the location of the fan-out

bracket on the buffer tubes as shown in

Figure 23 to determine the length required.

12.4

Install fan-out assemblies and connectors

according to the instructions provided with the

BTF kits.

12.5

Route the buffer tubes around the radius

guides and secure the fan-out assemblies to the

fan-out bracket as shown using a cable tie

(Figure 24).

Figure 23

Figure 24

Figure 25

12.6

Route the connectorized fan-out tubing

around the guides and plug connectors into the

connector panel (Figure 25). Refer to the

previous connector care caution to avoid

damaging the connectors during installation.

12.7

Label the connector end of the pigtail

with its port identifier. Record information

appropriately on the record label inside the

front door (Figure 18).

IMPORTANT:

Accurate record keeping is

imperative for an organized installation.

NOTE:

The splice tray holder and its mounting

bracket should be reinstalled to allow future splicing

capabilities.

13. Installing Drop Cable

13.1

The EDC is designed to accept up to six

drop cables. Feed 3 meters (10 feet) of drop

cable through the fitting you installed on the

right at the base of the closure.

1) Route three complete loops of the subunit

around the radius guides (Figure 28).

2) Match the subunits to the corresponding

panels and simulate how they will lie.

3) Mark the length on the subunit and trim the

cable to this length.

13.2

Gently secure cable with no central

members to the bracket using cable ties.