STANDARD RECOMMENDED PROCEDURE 003-139-AEN | ISSUE 1 | JANUARy 2017 | PAGE 3 OF 13

4.

Connector and Adapter Cleaning

4.1

Cleaning the LC adapters with an LC port cleaner

before each mating is recommended (Figure 2).

Figure 2

4.2

The use of an MTP Connector and Port

Cleaning Tool to clean MTP connectors and ports

before each mating is recommended (Figure 3).

Figure 3

5.

The Functionality of the Tap Module Splitters

Directionality

5.1

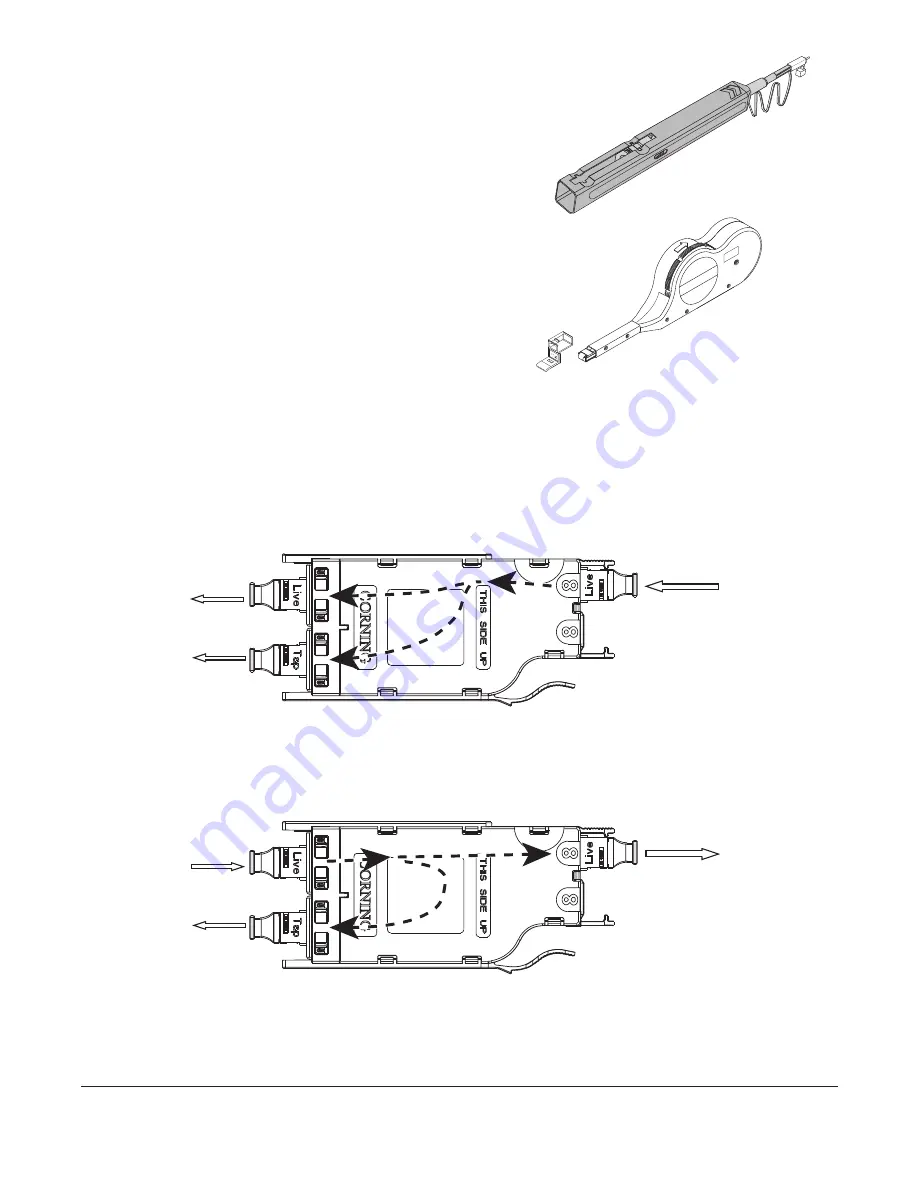

In simplest terms, the splitters inside an MTP Tap module act like a divider of a one-way traffic

flow – in this case, light.

The module has two Live ports which interface with the network. Each of these ports have eight fibers,

of which four are TX and four are RX ports. In the case of TX fibers, these are the input to the splitters

with the two outputs of the splitters going to the other Live port and Tap port as shown in Figure 4.

Figure 4

In the same fashion, the Live port on the front of the modules serves as an input for the six additional

splitters. The output of those splitters route to the Live port in the rear of the module and the Tap port,

as shown in Figure 5).

Figure 5

Tables 2 through 5 in Sections 8 and 9 provide a full representation of the source and output positions.

HPA-0738

HPA-0754

Tap Output (RX)

on four of eight fibers

Live Output (RX)

on four of eight fibers

HPA-0995-EDGE8

Live Source (TX)

on four of eight fibers

Tap Output (RX)

on four of eight fibers

Live Source (TX)

on four of eight fibers

HPA-0996-EDGE8

Live Output (RX)

on four of eight fibers