PSG-1400

Rev. 07/24/07

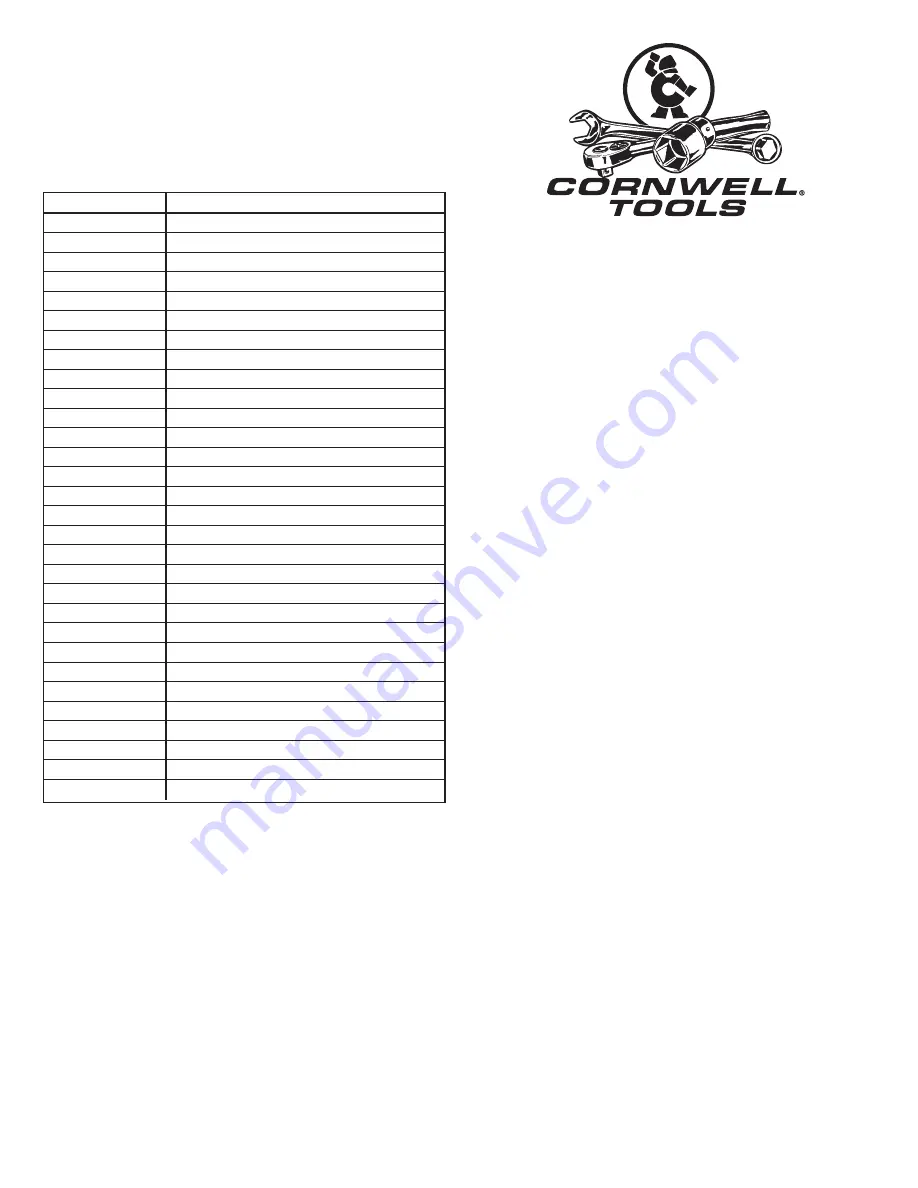

PARTS LIST - PSG-1400

itEM NO.

DEsCriptiON

RS1700RK

Repair Kit*

RS1701-1.

Air Nozzle 1.MM

RS1704-1.

Fluid Nozzle 1.MM

RS1705

Packing Screw

RS1706

Teflon Seal

RS1707

Washer

RS170

Spring

RS1709

Brass Baffle (Left-Hand Thread)

RS1710

Gasket

RS1711

Connector

RS171

Air Valve Assembly

RS1714

Fan Adjustment

RS1715

Control Knob

RS1716-1.

Paint Needle 1.MM

RS1717

Spring

RS171

Lock for Fluid Control Knob

RS1719

Fluid Control Knob

RS1720

Screw

RS1722

Trigger

RS1724A

Screw & Nut

RS1725A

Pin & Clip

RS1726

Air Connection

RS170A

Spanner

RS171

Socket Spanner

RS172

Brush

RS17

Air Adjusting Valve Assembly

RS900PKG

Material Filter (10 Pack)

RS9612N-0

Hanger

PSG-600CC

Replacement Aluminum Cup and Lid

PSG-RS1729AL-1 Gasket for Aluminum Lid (5 pack)

*Includes all parts as asterisked on parts diagram.

WARRANTY

Cornwell warrants its air tools for a period of 1 year to

the consumer. We will repair any air tool covered under

this warranty which proves to be defective in mate-

rial or workmanship during the warranty period. In

order to have your tool repaired, return the tool to any

Cornwell Authorized Warranty Center, freight prepaid.

Please include a copy of your proof of purchase and a brief

description of the problem. The tool will be inspected and

if any part or parts are found to be defective in material

or workmanship, they will be repaired free of charge and

the repaired tool will be returned to you freight prepaid.

This warranty gives you specific rights. You may also have

other rights which vary from state to state.

The foregoing obligation is Cornwell’s sole liability under

this or any implied warranty and under no circumstances

shall Cornwell be liable for any incidental or consequential

damages.

Note: Some states do not allow the exclusion or limita-

tion of incidental or consequential damages so the above

limitation or exclusion may not apply to you.