© Copyright, Core Protection Systems Ltd, 2021

Page 19

3.2.4 Storage

There may be particular required storage procedures depending on your working environment. This

should be confirmed with your organisational Respiratory Health and Safety Officer.

Corpro’s storage recommendations are the same for both the HM1400 half mask and the FFM1600 full

face mask. Please see section 3.1.4 for storage advice.

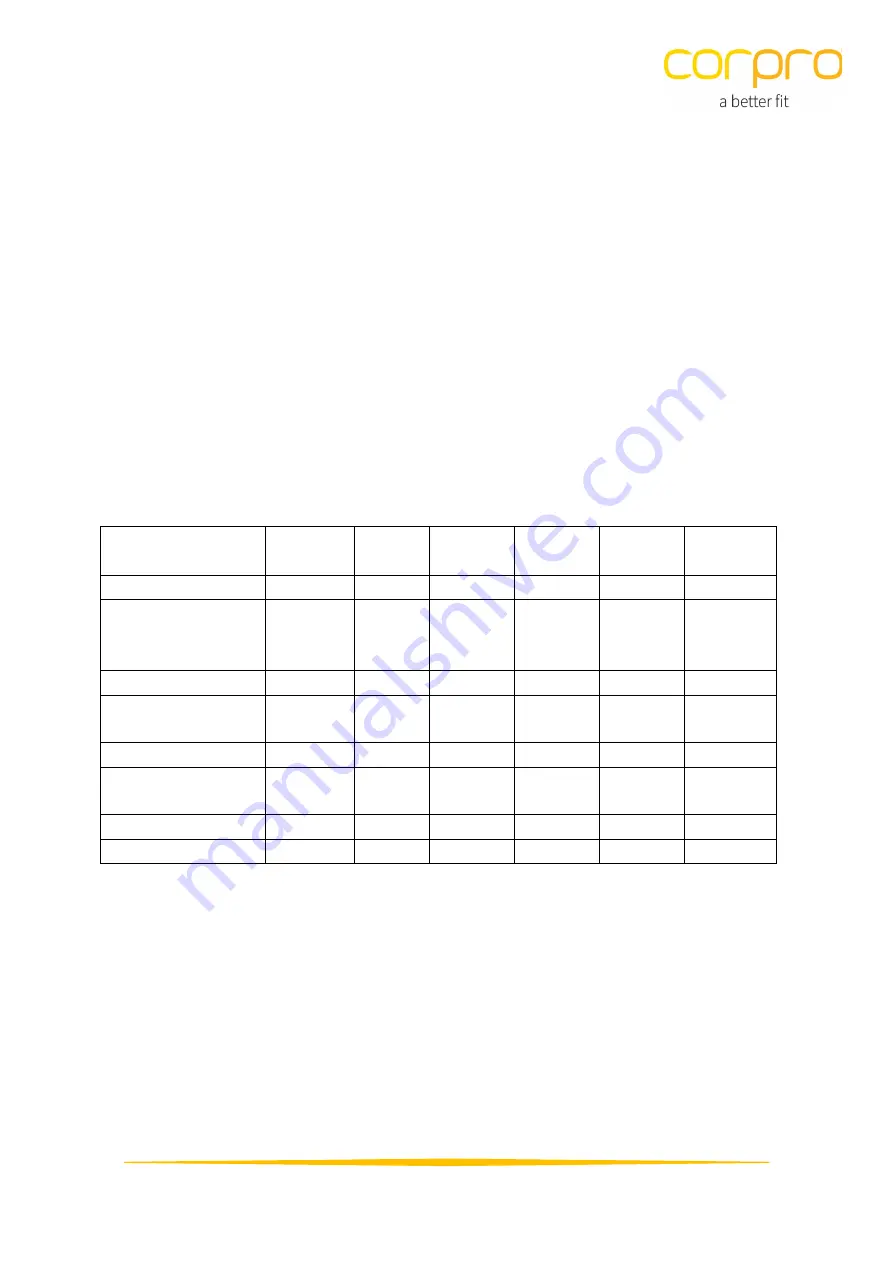

3.2.5 Maintenance Intervals

To summarise, based on the information presented above, Corpro recommends the following

maintenance intervals:

Interval

Task

Before Use After Use 3 months 6 months 12 months 60 months

Cleaning/Disinfecting

X

X

Fit Test / Leak

Tightness Test

X

(First

Use)

X

Valve Replacement

X

A

X

A

X

A

Face Seal

Replacement

X

Inlet Gasket Change

X

Inner Mask

Replacement

X

General User Checks

X

X

Fit Check

X

X

As previously mentioned, depending on your environment, risks and wear frequency, certain

maintenance tasks may be required more frequently. This needs to be established by an

organisational risk assessment.

If components have been replaced (e.g., valves, gaskets, etc), a fit check and a general user check must

be carried out in advance of mask’s next use.

All aforementioned tasks should be performed if a mask has been in storage for a long period, and at

least once a year.