1

‐

8

HEARING

PROTECTION

Always

use

ear

protection!

When

your

machine

is

running,

noise

generated

by

the

machine

may

come

from

the

following:

Saw

blade

during

cutting

or

material

feed

mechanism

Wire

brush

unit

Chip

conveyor

unit

Speed

reducer

Hydraulic

motor/pump

Belt

transmissions

variable

speed

motors

Blade

motor

Coolant

pump

Drive

wheel

Parts

not

assembled

tightly

causing

mechanical

vibration

Our

products

pass

noise

testing

less

than

78

dBA.

Noise

level

vary

according

to

working

conditions

and

we

recommend

ear

plugs

or

other

hearing

protection

at

all

time.

If

your

machine

produces

an

undesirable

noise

while

it

is

running,

you

should:

1.

Make

sure

all

maintenance

tasks

have

been

performed

following

the

prescribed

maintenance

schedule

(Refer

to

Section

8).

2.

If

maintenance

does

not

seem

to

solve

the

problem,

follow

the

troubleshooting

procedures

under

Section

9.

CE

COMPLIANCE

Cosen’s

CE

model

is

designed

to

satisfy

regulations

of

the

Council

Directive

on

the

approximation

of

the

laws

of

the

Member

States

relating

to

machinery

(2006/42/EC)

‐

Annex

I

Essential

health

and

safety

requirements

relating

to

the

design

and

construction

of

machinery.

RISK

ASSESSMENT

Risk

assessment

generally

takes

account

of

intended

use

and

foreseeable

misuse,

including

process

control

and

maintenance

requirements.

We

made

every

effort

to

avoid

any

personal

injury

or

equipment

damage

during

the

machine

design

stage.

However,

the

operator

(or

other

people)

still

needs

to

take

precautions

when

handling

any

part

of

the

machine

that

is

unfamiliar

and

anywhere

on

the

machine

that

has

potential

hazards

(e.g.

the

electrical

control

box).

Summary of Contents for SH-3026L

Page 2: ......

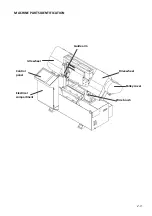

Page 8: ......

Page 13: ...1 5 Illustration Emergency Stop Emergency Stop Button ...

Page 15: ...1 7 Illustration Safety Labels ...

Page 20: ...2 4 FLOOR PLAN Machine top view Machine front view ...

Page 21: ...2 5 Machine front view ...

Page 22: ......

Page 32: ......

Page 48: ......

Page 50: ...5 2 ...

Page 51: ...5 3 ...

Page 52: ...5 4 ...

Page 53: ...5 5 ...

Page 54: ......

Page 55: ...6 1 Section 6 HYDRAULIC SYSTEM HYDRAULIC CIRCUIT DIAGRAM ...

Page 56: ...6 2 ...

Page 62: ......

Page 79: ...6 5 4 1 2 3 7 8 9 SH 3026L 2015 12 4 COLUMN ASSEMBLY S3026 11000 立柱組 SERIES PART LIST 10 7 ...

Page 81: ...1 4 3 2 HEIGHT CONTROL ASSEMBLY SH 3026L 2015 12 8 S3026 11400 高度控制組 SERIES PART LIST 10 9 ...

Page 83: ...SH 3026L 2015 12 8 CONTROL BOX ASSEMBLY S3026 13000 控制箱組 SERIES PART LIST 5 1 3 4 2 10 11 ...

Page 85: ...3 2 5 4 1 VISE ASSEMBLY SH 3026L 2015 12 8 S3026 22000 虎鉗組 SERIES PART LIST 10 13 ...

Page 88: ...SH 3026L 2015 12 10 S3026 30000 鋸弓組 SAW BOW ASSEMBLY SERIES PART LIST 5 13 3 4 8 10 16 ...

Page 104: ......

Page 105: ......