4-10

No

Item

Function

Description

The laser light automatically turns off in 90

seconds to prolong light bulb lifetime.

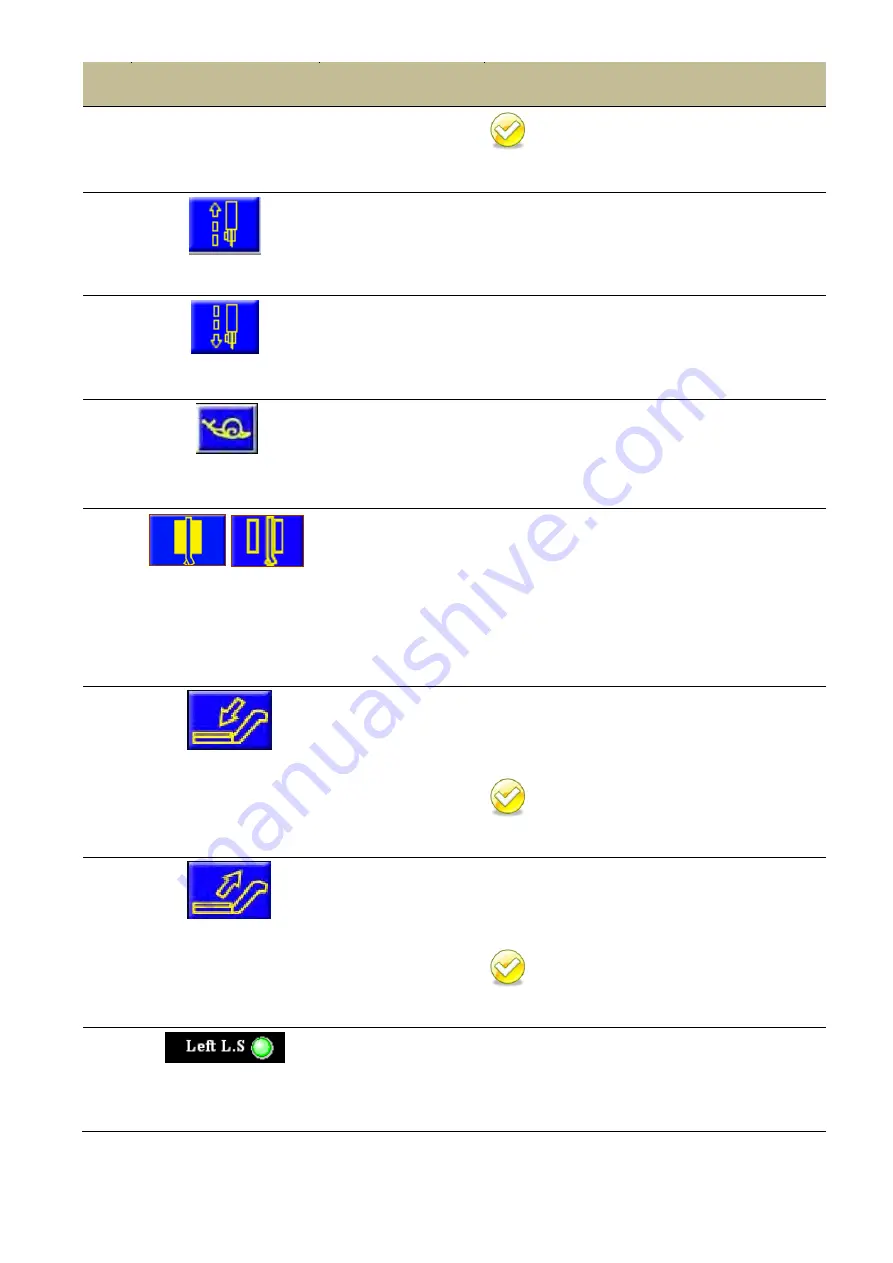

11

Guide arm up

Press this button to bring the guide arm up away

from the workbed. Use this function when you

need to adjust the distance between the guide

arm and the workbed/material.

12

Guide arm down

Press this button to bring the guide arm down

toward the workbed. Use this function when you

need to adjust the distance between the guide

arm and the workbed/material.

13

Slow material feeding

mode

Used only when under Manual Feeding mode.

When the slow material feeding mode is turned on,

the material feeding speed will dramatically reduce to

help you position the work piece precisely.

14

Tungsten inserts

clamp/unclamp switch

Press this button to clamp tungsten carbide

inserts. Press again to unclamp.

The carbide inserts will automatically clamp the

blade when the saw blade start button is

pressed. This safety design is incorporated in the

program to protect both the user and the blade

during cutting.

15

Scraper chip conveyor

reverse

Press to reverse the scraper chip conveyor.

A solid scraper chip conveyor icon indicates the

conveyor has been reversed.

Scraper chip conveyor forward must be

turned off first to start reversing.

16

Scraper chip conveyor

forward

Press to forward the scraper chip conveyor.

A solid scraper chip conveyor icon indicates the

conveyor has been forwarded.

Scraper chip conveyor reverse must be

turned off first to start forwarding.

17

Left limit switch

ON/OFF

When the movable workbed feeds to the very

left end and touches the left side limit switch, the

workbed will stop and the green light will come

on.

Summary of Contents for SVT-6070H

Page 2: ... ...

Page 4: ... ...

Page 10: ... ...

Page 15: ...1 5 Illustration Emergency Stop Emergency Stop ...

Page 20: ...1 10 Illustration Safety Labels ...

Page 25: ...2 3 MACHINE PARTS IDENTIFICATION ...

Page 26: ...2 4 FLOOR PLAN Machine top view Machine side view ...

Page 36: ... ...

Page 60: ... ...

Page 62: ...5 2 Fig 5 1 Control panel layout ...

Page 63: ...5 3 Fig 5 2 Circuit board layout ...

Page 64: ...5 4 Fig 5 3 Power supply layout ...

Page 65: ...5 5 Fig 5 4 PLC I O layout ...

Page 66: ... ...

Page 67: ...6 1 Section 6 HYDRAULIC SYSTEM HYDRAULIC DIAGRAM ...

Page 68: ...6 2 Fig 6 1 Hydraulic layout ...

Page 104: ... ...

Page 105: ... ...