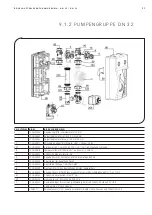

2 8

A-1

Return to the heat generator (boiler)

A-2

Full metal thermometer with immersion sleeve, integrated in the ball valve (return)

A-3

Temperature sensor

B

Heating pump

C

3-way mixing valve

C-1

Return from the consumer circuit (storage tank)

C-2

Flow to the consumer circuit (storage tank)

C-3

Actuator with constant temperature controller for the mixing valve

C-4

Check valve, can be opened

D

Return pipe

E

Design insulation with optimised function

F-2

Full metal thermometer with immersion sleeve, integrated in the ball valve (flow)

F-1

Flow from the heat generator (boiler)

2 . 3 E Q U I P M E N T

2 . 4 F U N C T I O N

Return temperature maintenance of solid fuel boilers, wood-fired heating systems

and stove heating systems

The return temperature maintenance prevents the temperature in the boiler

from falling under the dew point, thus reducing the contamination of the boiler.

The return temperature maintenance is connected to a buffer tank. When the boiler circuit

has reached the set opening temperature (according to the specifications of the

boiler manufacturer), the performance of the pump can be used to charge the buffer tank.