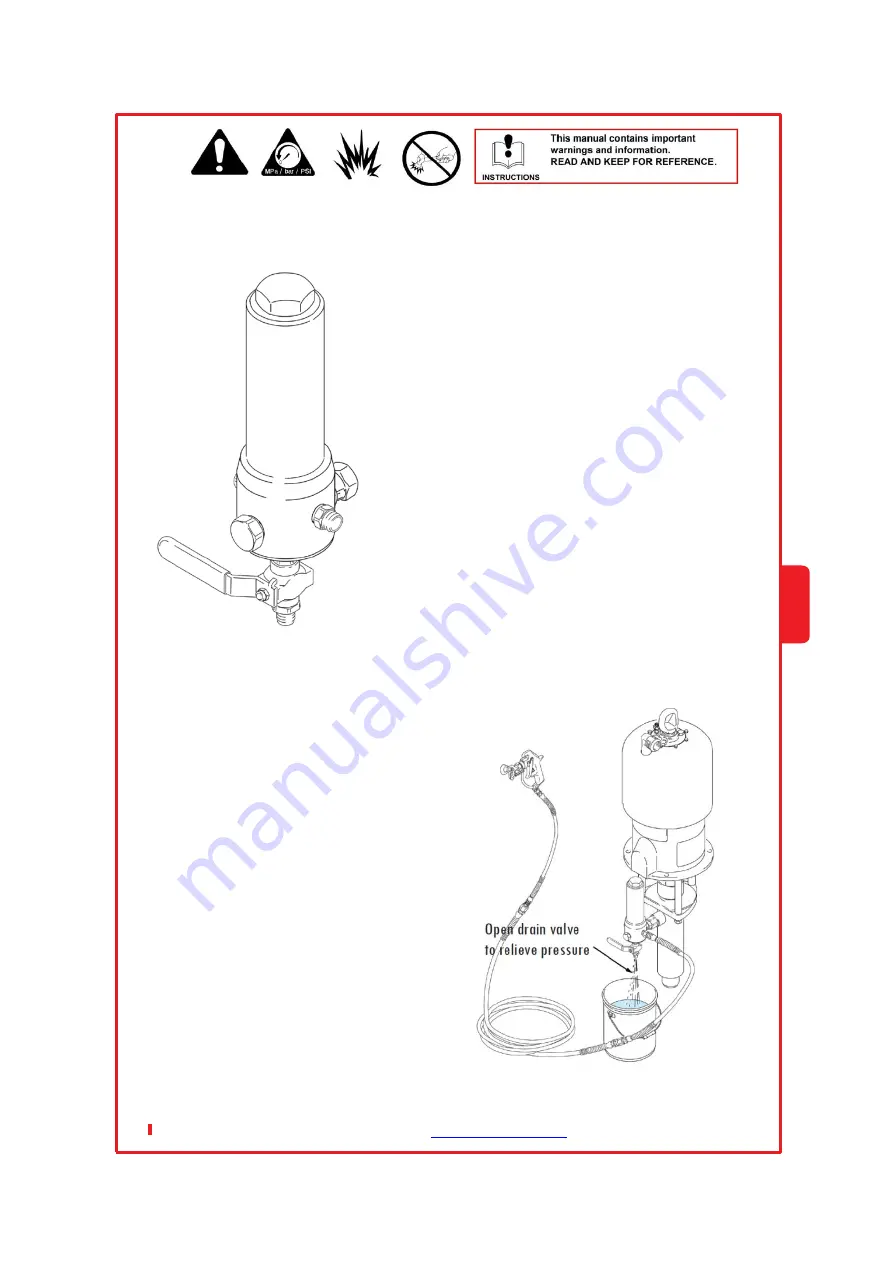

Operation

Before

operating

the

equipment,

be

sure

the

drain

valve

is

closed.

Flush

the

equipment

with

a

compatible

solvent

to

remove

oil

used

for

factory

testing

and

rust

prevention.

If

you

notice

excessive

surging

at

the

spray

gun,

shut

off

the

pump,

trigger

the

gun to

relieve

fluid

pressure,

and

open

the drain

valve

(D)

at

the

bottom

of

the surge

tank.

See

the

left

figure,

after the

tank

is

drained,

close

the

drain valve

and

resume

operation.

Be

sure the

drain

valve

is

fully

closed

when spraying

and

fully

open

when

draining or

circulating

fluid

to

get

the

best results

and

reduce

wears

on

the

valve

.

Service Notes

Clean

all

parts

thoroughly

when

disassembling.

Check

parts

carefully

for

damage

or

wear,

replace

as

needed.

Numbers

in

parentheses

in

the

text

refer

to

the

parts

drawings.

Check

periodically

for

leakage

from

the

small

holes

near

the

top

and

bottom

of

the

fluid

filter.

If

you

find

leakage

at

the

holes

or

anywhere

else,

replace

the

seals

promptly.

Inspect

the

sealing

surfaces

for

nicks

or

scratches

that

might

cause

leakage.

Do

not

damage

the

sealing

surfaces.

When

reassembling

filters

after

cleaning

or

servicing,

be

sure

to

install

the

filter

support

as

shown

in

the

parts

drawings.

Do

not

install

it

upside

down.

Pressure Relief Illustration

COSMOSTAR

Fluid Handling Equipment

e-mail:

sales@cosmostar.net

10

Fluid Outlet Filter