18

ENG

LI

SH

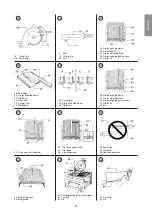

6.2 Attaching and adjusting the rip fence

1. Attach the rip fence guide holder (45) in the slot (46) in the table.

2. Set it to the desired width according to the scale and lock the

knob (48).

3. Undo the locking knob (47).

4. Slide the fence (49) into the holder (45) so that it stops just where

the saw blade (36) emerges from the table (see the index line

50). Note: This is important to prevent the workpiece from being

ejected back towards the operator if it gets squashed between the

rip fence and saw blade. Note: The setting should be changed

depending on the thickness and angle setting.

5. Lock the knob (47) so that the fence is fastened in place.

Note:

The rip fence guide can be mounted in the holder (45) in four different

ways.

The rip fence must be parallel to the saw blade, check it as follows:

1. Set the saw blade to its maximum height above the table.

2. Mark one of the teeth.

3. Rotate the blade by hand until the marked tooth is level with the

table, measure the distance from the tooth to the rip fence. Use

a try square, set square, etc.

4. Rotate the blade backwards by hand until the marked tooth is

level with the table, measure the distance from the tooth to the rip

fence at that place. If the two distances (A) and (B) are the same,

the rip fence is parallel to the saw blade.

5. Adjust the rip fence guide if necessary: the holder (45) has an

adjustment screw on the outside, undo the locking knob (48)

slightly, turn the adjustment screw until the rip fence is parallel

to the saw blade. Tighten the locking knob (48).

6. Make sure that the saw blade can rotate freely and that all safety

guards work properly.

Note:

Do not lift the rip fence, the holder can break.

6.3 Mitre guide

1. Attach the fence (57) to the mitre guide (58).

2. Fit the mitre guide (58) to the table by sliding the long aluminium

section of the mitre guide into the track (59) at the front of the

table.

Summary of Contents for 2502W

Page 107: ......