9

EN

GL

IS

H

Maintenance

Changing the hydraulic oil

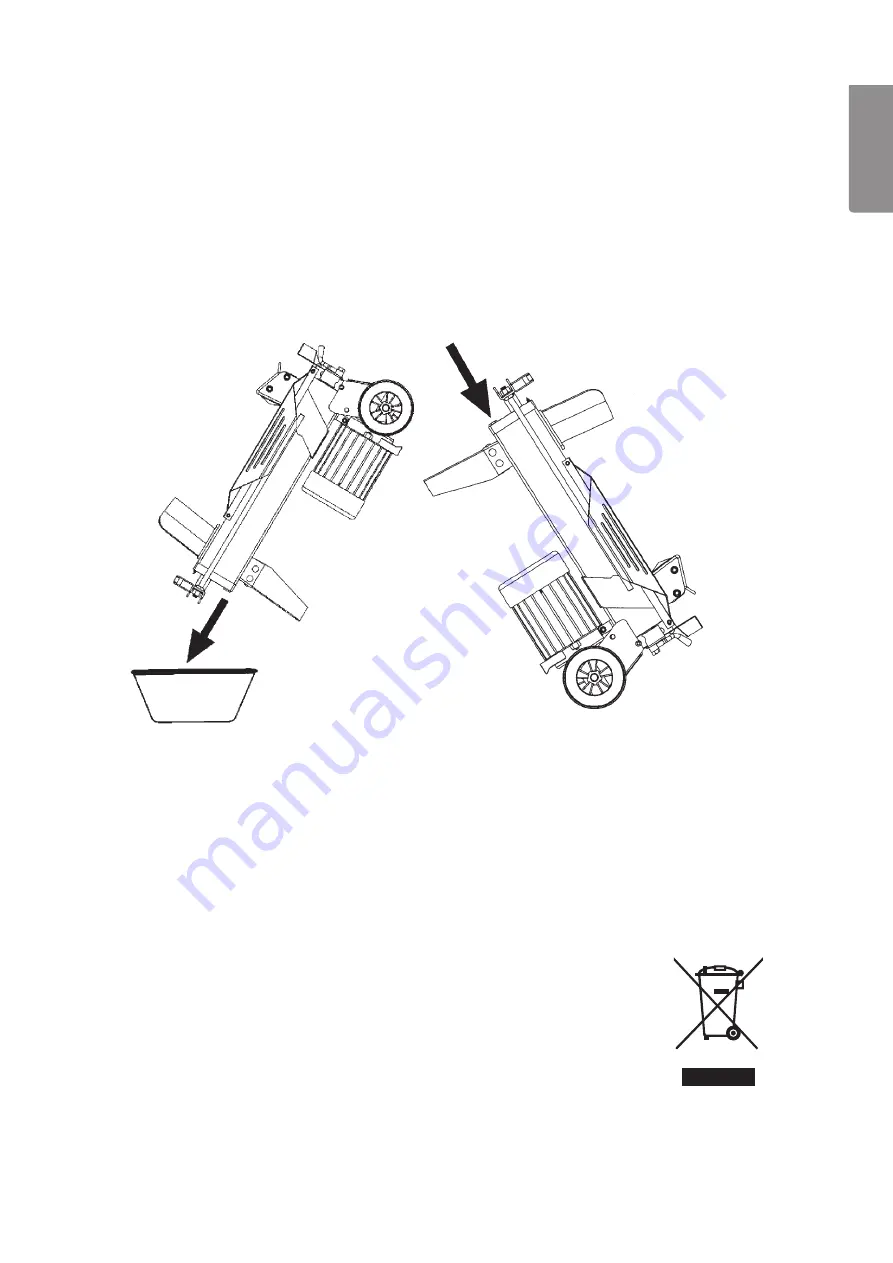

The hydraulic oil has to be changed at regular intervals (approx. 150 hrs) according to the following:

1. Ensure that the pressure plate is in its original position and disconnect the power cord.

2. Unscrew the oil plug.

3. Lift the pull handle and tip the log splitter over a collecting vessel which holds at least 4 litres and wait until

all the oil has run out.

4. Tip the log splitter so that the motor side is up and fill using good quality hydraulic oil (approx. 2.4 litres)

5. Wipe the dipstick and place it in the tank when the log splitter is in a vertical position. Pull it back out and

take a reading. The oil level should be between the two markings on the dipstick.

6. Clean the oil plug and screw it back properly so that the oil does not leak out.

7. Check the oil level regularly and when necessary, top it up.

Keep the cleaver sharp!

• Keep the cleaver sharp by regularly filing off the burrs of the cutting edge using a fine-toothed metal file.

Other Maintenance

• Always unplug the plug before servicing or making adjustments.

• Ensure that all power cables, plugs and switches are undamaged and in good working order.

• Clean all of the surfaces on the log splitter using a brush and dry cloths.

• Store the machine in a dry, clean and non-corrosive environment out of reach of children. Ensure that

the storage temperature does not fall below −25° C.

• Ensure that all screws and nuts are fastened, especially the drawbar nuts (beside the handle).

Protect the environment

Sort your waste and recycle products instead of throwing them away. All machines, hoses

and packing material should be sorted and handled according to local environmental

regulations.

Summary of Contents for WS4T-37

Page 2: ......

Page 11: ...11 ENGLISH Exploded view...

Page 21: ...21 SVENSKA Spr ngskiss...

Page 31: ...31 NORSK Sprengskisse...

Page 41: ...41 SUOMI Kokoonpano...

Page 51: ...51 DEUTSCH Explosionszeichnung...

Page 54: ......

Page 55: ......