5

EN

GL

IS

H

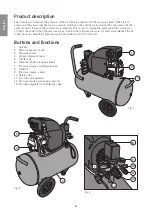

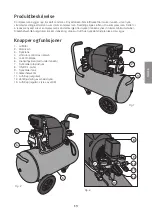

Fig. 4

Fig. 5

Fig. 6

Fig. 7

Getting started

1. Attach the wheels and rubber feet (Fig. 4 –6) to the pressure vessel.

2. Attach the air filter to the compressor. Fig. 7.

3. Place the compressor in a dry and well ventilated place.

4. Make sure that it is stable and cannot tip over.

5. Make sure that the oil level is up to the red circle in the oil

level window (4).

6. Connect the mains lead to a permanently installed 230 V

wall socket.

N.B.

Before using the compressor for the first time: Open the drain tap

(6) in the bottom of the pressure vessel, switch the compressor

on using the ON/OFF button (9) and let it run for 10 minutes to

lubricate all the moving parts. Close the drain tap.

Use

1. Check the oil level in the window (4).

2. Attach a suitable air tool: blow gun, spray gun, tyre inflator, etc.

3. If necessary: Read the instruction manual of the connected air tool and set the recommended working

pressure using the regulator (12).

4. When you have finished work and the compressor has been turned off, the pressure must be released

by pulling out the safety valve (10).

• Use SAE 30 compressor oil at temperatures over +10 °C.

• Use SAE 10 compressor oil at temperatures under +10 °C.

Motor overload cut-out

If the safety cut-out has tripped, the motor has been overloaded in some way.

The button on the motor overload cut-out (2) will pop out a couple of millimetres

when it has been tripped and is reset by pushing it back in.

There are a number of possible reasons why the overload cut-out might trip such as

a voltage drop caused by the use of long extension leads, low ambient temperature

(under 10°C), or that the pressure switch is not used to turn the compressor on/off in

the event of a power cut for example.

Summary of Contents for ZB-0.12/8-50FL

Page 2: ...2...