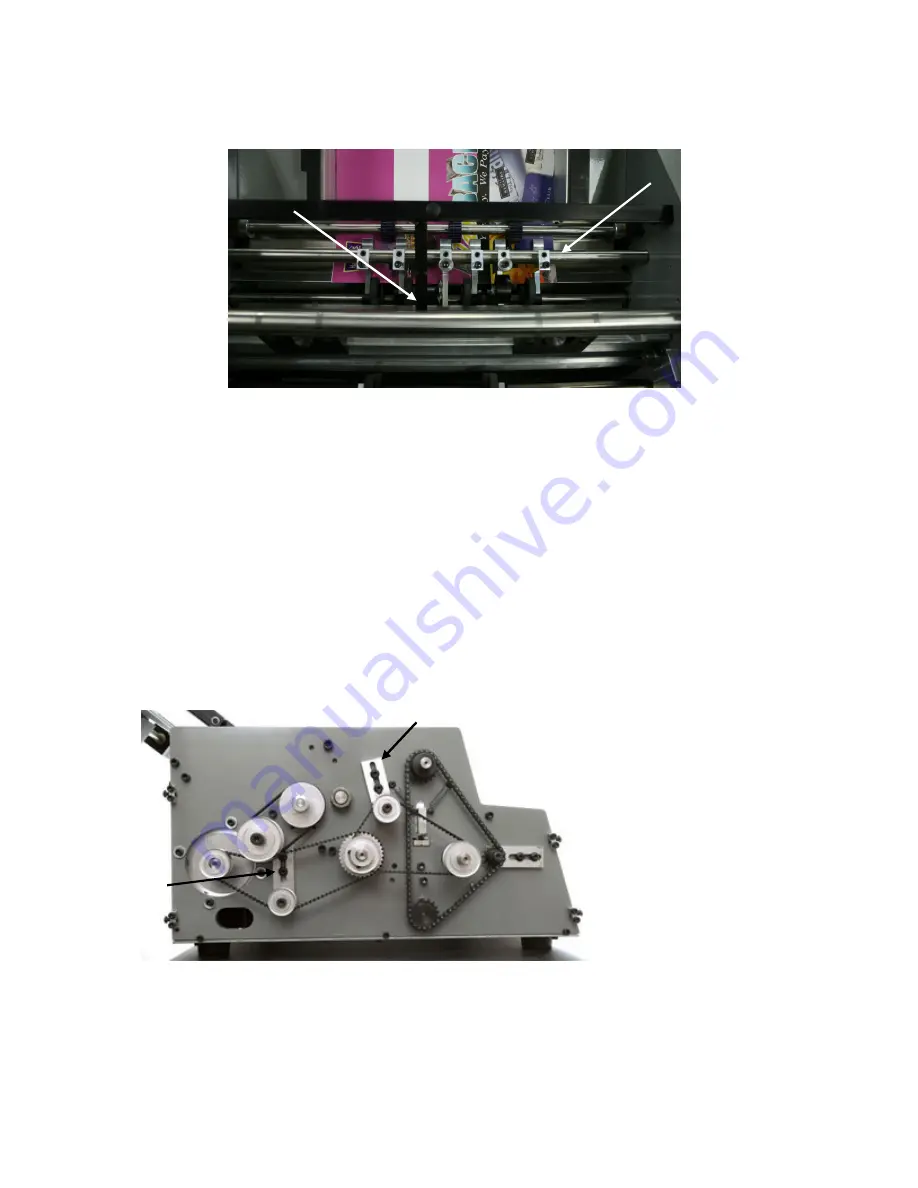

PERF SHAFT & STRIKE PLATE

A

– Support Bar – F-0232

This is the shaft that the roller wheels

and perf score are mounted on.

B

– Lower Sensor Eye Assy. – S-AAM-0230

Located in the platen strike plate, directly

below the upper sensor. These two must

align.

REMOVING THE PERF SHAFT

Loosen the operator side cover. Locate and remove the perf shaft lock collar.

Next, remove the non-operator side cover. Loosen both of the belt tensioner idler pully’s. You do

not need to remove these as loosening them will allow enough movement to free the pully’s of

the perf shaft. Slide the perf shaft out the pulley side.

It is only necessary to slide the shaft out about 6 to 8 inches. With the shaft slid to the side, you

can access the lower hubs and reconfigure them as needed to complete any job. After you have

configured the lower shaft, replace the shaft into its bearing and secure the shaft collar. The

shaft should not be able to

move side to side. With

both drive belts in

Position, re-tension the

belt idlers and tighten

while applying constant

firm pressure on the belts

by pushing down on the

tops of the brackets with

the large T-handle wrench

supplied. Replace covers.

Align upper assemblies

accordingly.

14

Loosen both screws

Loosen both

screws

A

B