Ussc

11

CHIMNEY

Your wood stove may be hooked up with a 6” factory built or masonry chimney. If you are using a fac-

tory built chimney, it must comply with UL 103 or CSA-B365 standard; therefore it must be a Type HT

(2100°F). It is extremely important that it be installed according to the manufacturer’s specifications.

If you are using a masonry chimney, it is important that it be built in compliance with the specifica-

tions of the National Building Code. It must be lined with fire clay bricks, metal or clay tiles sealed

together with fire cement. (Round flues are the most efficient).

The interior diameter of the chimney flue must be identical to the stove smoke exhaust. A flue which

is too small may cause draft problems, while a large flue favours rapid cooling of the gas, and hence

the build-up of creosote and the risk of chimney fires. Note that it is the chimney and not the stove

which creates the draft effect; your stove’s performance is directly dependent on an adequate draft

from your chimney.

The following recommendations may be useful for the installation of your chimney:

1. DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE.

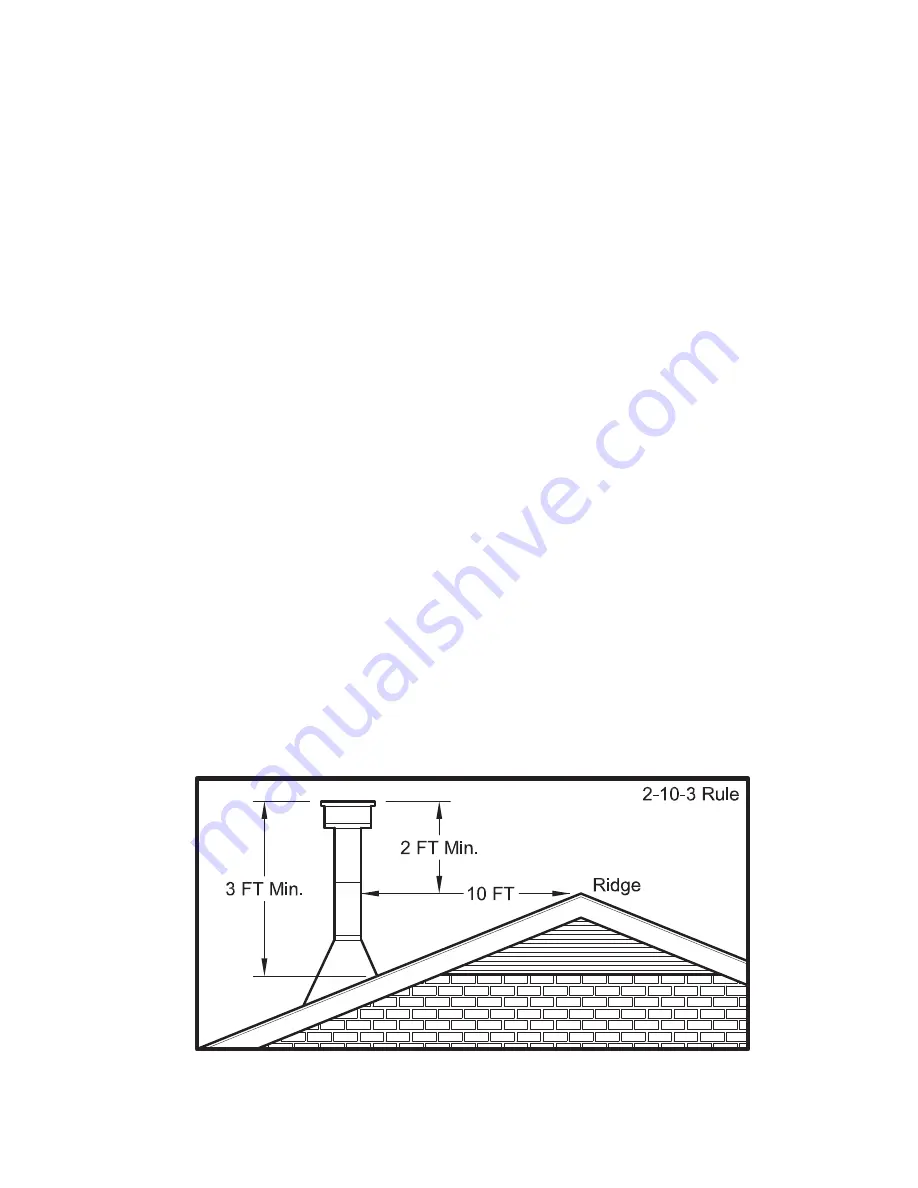

2. It must rise above the roof at least 3’ (0.9m) from the uppermost point of contact.

3. The chimney must exceed any part of the building or other obstruction within a 10’ (3.04m)

distance by a height of 2’ (0.6m).

4. Installation of an interior chimney is always preferable to an exterior chimney. Indeed, the

interior chimney will, by definition, be hotter than an exterior chimney, being heated up

by the ambient air in the house. Therefore the gas which circulates will cool more slowly,

thus reducing the build-up of creosote and the risk of chimney fires.

5. The draft caused by the tendency for hot air to rise will be increased with an interior chim-

ney.

6. Using a fire screen at the extremity of the chimney requires regular inspection in order

to insure that it is not obstructed thus blocking the draft, and it should be cleaned when

used regularly.

Summary of Contents for 2000

Page 22: ...22 Ussc NOTES ...

Page 23: ...Ussc 23 NOTES ...