Installation

4

Before Starting Installation

NOTICE This system is not designed for applications

involving salt water or brine! Use with salt water or brine

will void warranty.

Install this system during a time when the primary pump

will not be needed. Gather all supplies before starting.

Read all warnings and installation steps before you start.

Be prepared for water to leak from the coupling or

piping when disassembling or cutting the discharge pipe.

Protect system components, tools and supplies from

getting wet. Dry any work areas that get wet.

Basic Tools and Materials Needed

Large tongue-and-groove pliers

Tape measure

Socket wrench or 5/16” nut driver

Side cutters

Hacksaw (to cut PVC pipe)

Medium size pliers

Pencil

PTFE pipe thread sealant tape

PVC glue (solvent weld)

PVC pipe cleaner

Cloth towel

100-120 Ampere-Hour Marine Deep Cycle Battery

(sold separately)

Required Battery Capacity:

Single Battery: 120 ampere-hour maximum.

Double Batteries: 100 ampere-hours per battery

(200 ampere-hours total)

Risk of flooding. Can cause personal injury

and/or property damage. Do not turn the pump on until

all the fittings are glued and the glue has dried. Loose

fittings can explode off of pipes.

Installation

Risk of electric shock. Can shock, burn

or kill. At the circuit breaker or fuse box, turn off the

electrical power to the sump pump before beginning

this installation.

Setup

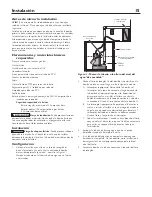

1. Locate the high water level in your sump pit (that is,

the water level at which the existing (primary) sump

pump starts - see Figure 1). Mark this point on the

discharge pipe with a pencil or marker.

2. Drain the sump pit as far as possible without running

the pump dry. Do this by:

A. Piggyback switch: Unplug the pump and switch

from the outlet, then unplug the pump from the

piggyback switch. Reset the circuit breaker or

reinstall the fuse and plug the pump directly into

the outlet. The pump will start. Drain the pit and

unplug the pump. OR

B. No piggyback switch: Reset the circuit breaker

or reinstall the fuse and use a non-conducting

broom handle or stick to raise the float switch;

the pump should start. Drain the pit and then

release the switch.

C. All installations: When the pit has drained, turn

off (open) the circuit breaker or remove the fuse

again to avoid electrical shock while working on

the installation.

3. Support the discharge pipe so that it can’t collapse

when you take it apart or cut it.

4. If your discharge pipe has a hose coupling,

disconnect the coupling. If not, cut the vertical

discharge pipe at any convenient spot above the

floor level.

5. Lift the pump and attached pipe out of the sump pit.

‘Start’ water level

of Primary Pump

Sump Pit

Check

Valve

Support the

Pipe before

cutting.

5761 0108

Mark pipe with

pencil here.

Figure 1 - Mark pipe at ‘start’ water level

Summary of Contents for CL1800DC

Page 24: ......