Installation • Operation

8

NOTICE During normal operation, the flashing

‘Pump Status’ LED indicates that the pump has run in

your absence. See Table II, Operating Code Displays.

6. Press and hold ‘System Test’ button. All LEDs will

light up, pump will run and buzzer will sound.

Release the button and LEDs should go off, pump

should stop, buzzer should stop.

7. The ‘Battery Status’ LED indicates the battery

capacity when the A.C. power is off.

A. Continuously ‘ON” - the battery voltage is

above 10.9 Volts Direct Current (10.9VDC) and

capacity is above 20%.

B. Slow Beep/Slow LED Flash - the battery’s

capacity is between 0 and 20%.

C. Fast Beep/Fast LED Flash - the battery is severely

discharged. The battery will continue to charge

(as long as the 115V AC power to the charger is

on) at the rate of .5 AH until the battery’s charge

is above 20%.

When the first warning occurs (slow beep/slow

flash), you will have approximately 2 hours (or less)

of pump operation left. The actual time of operation

will depend on the condition of the battery and may

be as little as 15 minutes.

8. Connect the Power Supply cable (supplied) to the

Charger/Controller’s Power Input jack.

LE D Display and Control Buttons

NOTICE When the unit is first plugged in, or when it first

receives power from the battery, the Battery Status LED

will flash for 3 seconds.

See Tables II, III, IV and V later in this manual for

Operating Code Displays, LED Function Displays, Error

Code Displays, and Control Button Functions.

NOTICE To activate any Control Button, depress and

hold it for 1 second.

Possible Remedies to Battery Problems

1. Wrong Battery Voltage

Reconnect charger to a 12 volt battery.

2. Reversed Battery Connections

Check all connections. The negative (black) on the

battery must connect to the negative (black) on

the charger, and the positive on the battery must

connect to the positive on the charger. Reversing the

battery connections will cause the ‘System Alert’ and

‘Silenced Audible Alarm’ LEDs to flash.

3. Thermal Runaway Condition

“Thermal Runaway” is the technical term for the

condition of the battery when some (or all) of the

cells have deteriorated to the point that they won’t

take a charge. In this case, replace the battery.

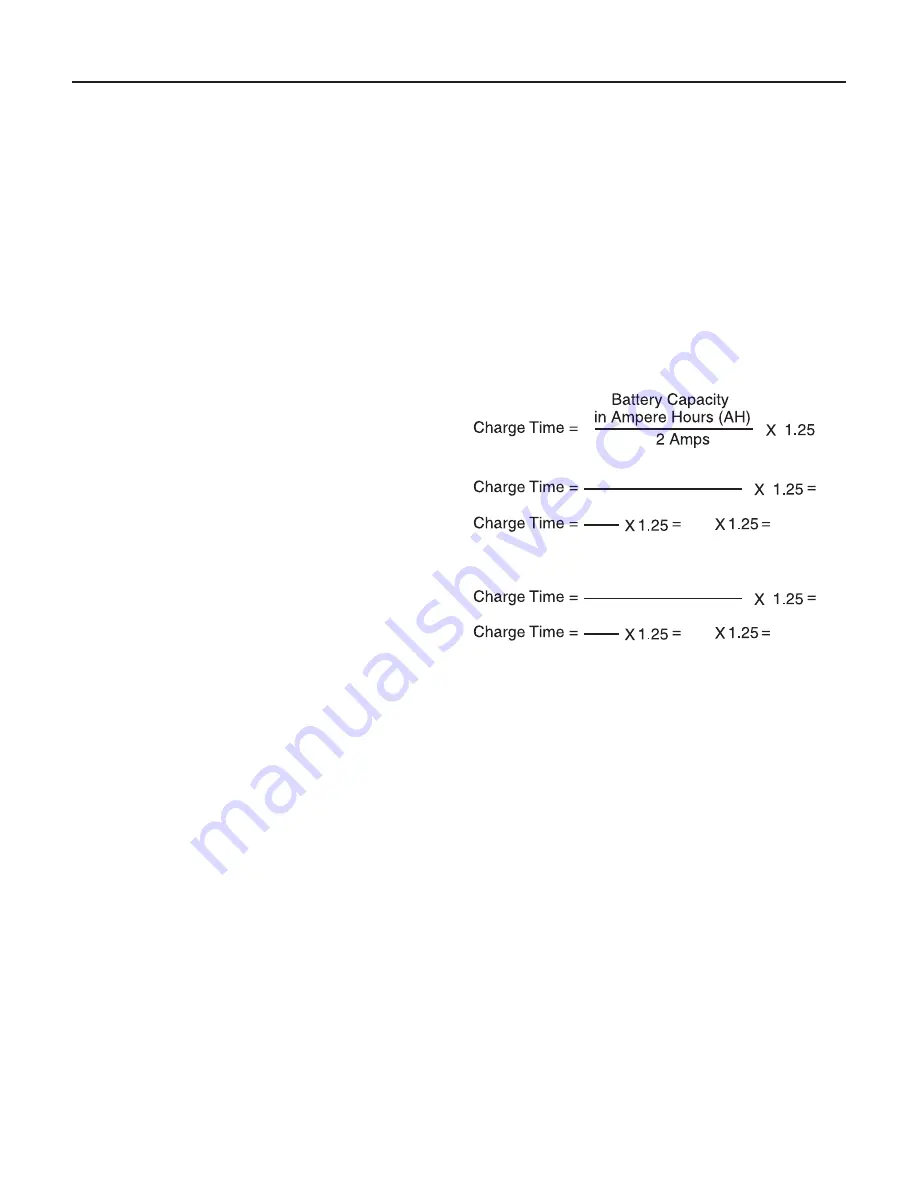

4. Charge Time Monitor – 1 and 2

Battery took too long to complete its charge. The

‘Charge Time Monitor’ will shut down the charger

after 84 hours of continuous charging.

Possible causes are:

A. Pump ran for a long period of time during

charging, or

B. Battery is too large for the charger (including

several batteries connected in a parallel circuit).

Apply the formula in Table I to determine whether

or not your battery is too large for the charger. If the

calculated charging time is more than 84 hours, use

a smaller battery (or group of batteries).

5. Excessive Battery Drain

Pump may have run for a very long time, discharging

the battery. In this case:

A. If 115VAC power is OFF, the charger shuts down

until the power comes back on, but the pump

will run as long as the battery charge lasts. You

may need to replace the battery if the battery

does accept a charge.

B. If 115VAC power is ON, the charger/controller

continues to try to charge the battery at a

charging rate of .5 AH until the battery charge is

more than 20%, at which point the charger will

resume charging at a rate of 2 AH.

C. If the pump is running and the AC power is on,

you may need to stop the pump to allow the

battery to charge.

2 Amperes

130 Ampere Hours

2

130H

65H

80H

81.25 Hrs

Less than 84 hours to charge; OK to use.

2 Amperes

160 Ampere Hours

2

160H

100Hrs

Capacity too large – use a battery of 130A-H or less.

NOTICE A 100AH battery in good condition should

charge in approximately 62 hours.

Example 1:

Example 2:

5764 0108

TABLE I – Battery Capacity Calculation

Summary of Contents for CL1800DC

Page 24: ......