INSTALLATION MANUAL

INSTALLATION

35

10) Repeat steps 8 an 9 on the opposite side.

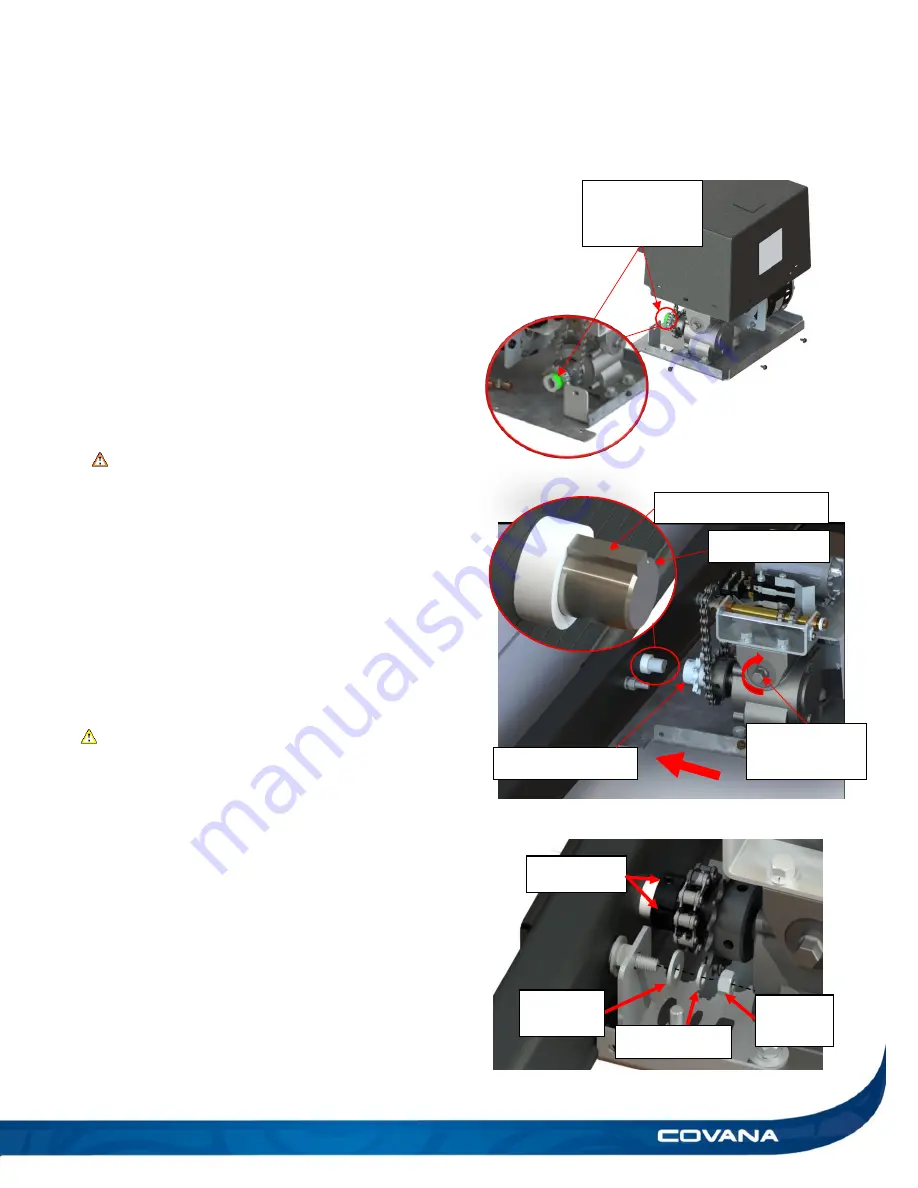

11) Remove the four slotted screws at the bottom of

the operator and remove the cover. Do not

discard these screws. (Figure 78)

12) Install the 3/16-3/16 x 5/8 in. square key into the

motorside

’s input shaft’s keyway. (Figure 79)

13)

Remove the tape on the operator’s sprocket.

14) Untighte

n the set screws of the operator’s

sprocket. (Figure 80)

15) Align the keyways of the input shaft and

operator’s sprocket together by turning the hex

shaft of the gearbox. (Figure 79)

WARNING

Do not turn more than 20 turns. If more turns are

required, the lower limit switch will have to be

reset. See

Limit switch adjustment section

.

16) Insert the motor-

side’s input shaft into the

sprocket. (Figure 79)

17) Fasten the operator to the two bolts from the

motorside with two 5/16 in. flat washers, 5/16 in.

lock washers and 5/16-18 hex nuts. (Figure 80)

18) Tighten both set screws in the sprocket. (Figure

80)

CAUTION

•

Do not overtighten the set screws or use

any power tools as it could damage some

components.

Remove the

tape on the

sprocket.

Figure 78

Hex shaft of

the gearbox

3/16-3/16 x 5/8 in. key

Operator sprocket

Input shaft

Figure 79

Flat

washer

Lock washer

5/16-18

hex nut

Set screw

Figure 80

Summary of Contents for C-HOR

Page 1: ...Revision 13 2018 04 23...

Page 53: ...INSTALLATION MANUAL APPENDIX 53 APPENDIX...

Page 54: ...54 APPENDIX INSTALLATION MANUAL Wiring diagram North America 60 Hz 120 VAC Operator...

Page 55: ...INSTALLATION MANUAL APPENDIX 55 Wiring diagram Europe 50 Hz 220 VAC Operator...