page-

26

LEGENDX COVER

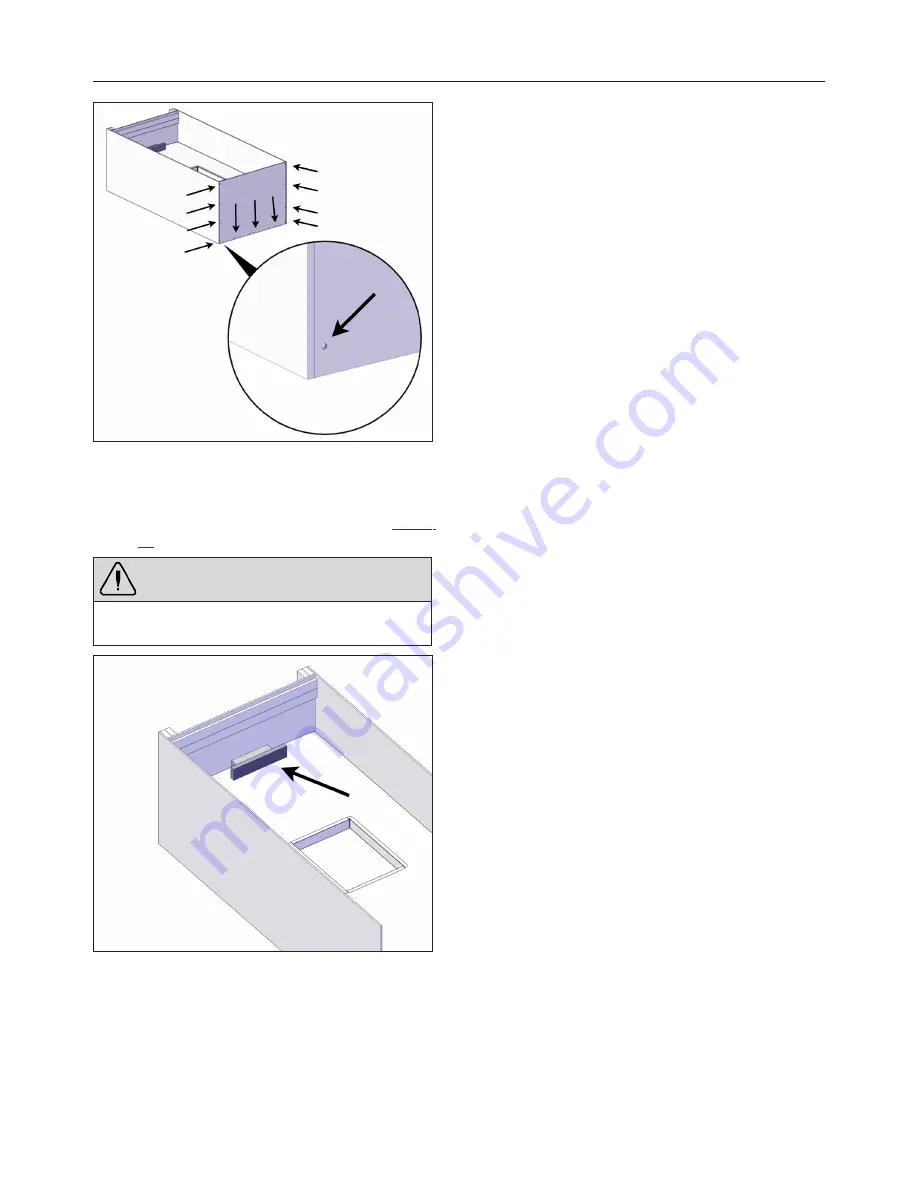

FIGURE 26: TOP BOARD REMOVAL

18. Unscrew the blocks that retain the panels.

Remove the fiberglass panels from the crate

and keep them in a safe location, see

.

WARNING

Panels are fragile. Handle with care, they can

easily be scratched or damaged.

FIGURE 27: PANEL BLOCK REMOVAL

243462

OWNER'S MANUAL

REVISION 2

Summary of Contents for LEGEND COVER

Page 1: ......

Page 2: ......

Page 16: ...page 14 LEGENDX COVER FIGURE 14 BATTERY SPECIFICATION LABEL 243462 OWNER S MANUAL REVISION 2...

Page 29: ...LEGENDX COVER page 27 HARDWARE IDENTIFICATION TABLE BAGS 243462 OWNER S MANUAL REVISION 2...

Page 70: ......

Page 74: ...page 72 LEGENDX COVER 243462 OWNER S MANUAL REVISION 2...

Page 82: ...page 80 LEGENDX COVER 243462 OWNER S MANUAL REVISION 2...