OASIS COVER page-

23

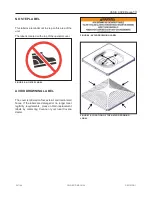

FIGURE 21: MOTOR FRAME ASSEMBLY REMOVAL

8. Reinstall the screws (2) on the operator

cover.

9. Use the 3/8″ (10 mm) socket wrench to

unscrew the hexagonal 1/4″ x 2″ lag bolts on

the bottom of both jacks. There are two lag

bolts per jack see

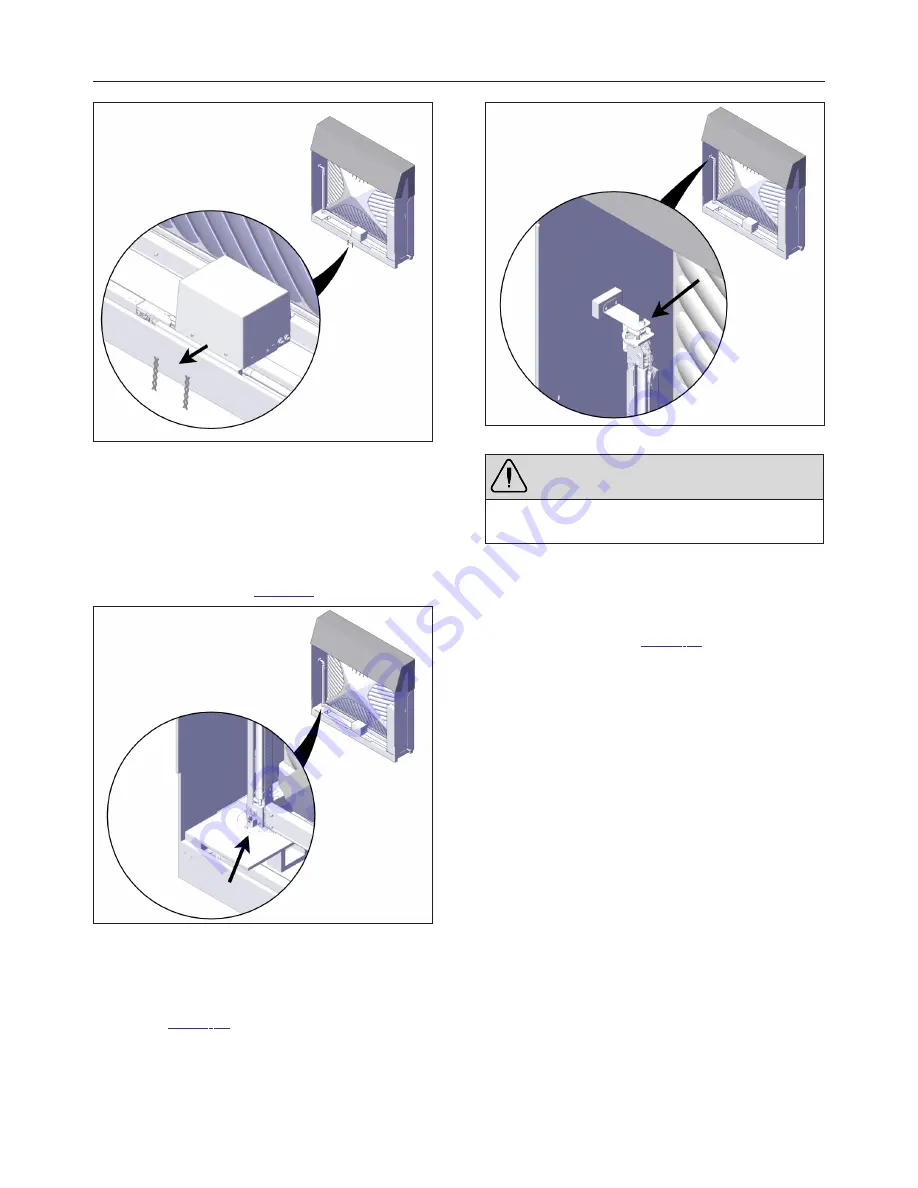

FIGURE 22: REMOVE BOTTOM LAG BOLTS ON JACKS

10. For each jack, use the 7/32″ (5.5 mm) Allen

key to loosen, but not fully remove, the 3/8″ x

1″ screw holding the jack to the top bracket

see

. There is one screw per jack.

Do not discard this screw and bushing; they

are required to assemble the cover.

FIGURE 23: LOOSEN TOP SCREW ON JACKS

WARNING

Do not remove the alignment bracket on the top of

the jack (red part).

11. With the help of another worker, remove the

motor frame assembly

from the crate.

Position one hand under the horizontal portion

of the motor frame and the other hand on the

vertical jack see

. Handle and carry

the assembly with care, so that the jacks

follow the natural bending of the U- frame.

Install the motor frame assembly on a level

surface and make sure it will not fall.

241146

OWNER'S MANUAL

REVISION 1

Summary of Contents for OASIS COVER

Page 1: ......

Page 2: ......

Page 54: ......

Page 59: ...OASIS COVER page 57 241146 OWNER S MANUAL REVISION 1...

Page 61: ...OASIS COVER page 59 241146 OWNER S MANUAL REVISION 1...

Page 63: ...OASIS COVER page 61 241146 OWNER S MANUAL REVISION 1...

Page 65: ...OASIS COVER page 63 241146 OWNER S MANUAL REVISION 1...