6

2019.01

silicon carbide, as diamond belts will not wear down as quickly. For beginners, we recommend starting with

the silicon carbide belts because of the cost savings. Once you have your process down, replace the grits you

use the most with diamond to reduce frequent belt changes.

• Polishing:

The polishing operation removes minimal surface material; some materials require both pre-polish

and polish steps. Pre-polish usually consist of 600g or finer silicon carbide or in the case of glass 2F or 4F

pumice powder applied to a cork belt. An excellent general-purpose polishing compound is optical grade

cerium oxide on a felt belt. Covington’s felt belts are made out of wool and will shrink if not used and stored

properly. Should you decide to polish with a felt belt, it is very important to make it the last process of the

day on your machine. We recommend turning off your water valve and using a spray bottle or a similar

device to keep the belt moist and charged with polishing compound. The valve can cause the belt to become

oversaturated with water and can wash the expensive polishing compounds off of the belt. When you are done

with your belt, let the machine run for a few extra minutes to wring out any extra water. We never recommend

washing the polishing compounds from your belt. Let your felt belt dry on the machine overnight. In the

morning, check to make sure it is completely dry (any moisture will cause it to mold), and then turn your

machine on with the felt belt on to stretch the belt back out to proper size. You can now take the felt belt off of

your machine and store it properly in a clean dry container such as a paper bag or cardboard box that will wick

any residual moisture away from the belt. A sealed plastic container is not ideal since it will hold moisture and

can cause the belt to mold.

• Belt Creeping:

If the belt moves to one side when sanding, the belt may be too loose or you may be grinding

above the backing plate. If you are needing to use the softer belt area above the backing plate, you may notice

more belt creeping than when you use the backing plate. To keep the belt centered over your drums, press hard

against the soft belt area and guide the belt with your piece. Make a belt tension adjustment by tightening or

loosening the vertical bolt with spring (see belt adjustment above).

• Wear Out:

A well-used belt will leave a finer finish than when the belt was new. A well-worn fine grit belt

may be used as a pre-polish belt. Sanding belts do not lose their usefulness until the belt backing wears out.

Material

Type

Belt

Material

Belt Mesh

or Polish

Notes

Glass

Felt

Cerium

I tried this combination and had great results!

**We recommend logging your trials using a chart like the one below. This helps you track

and repeat effective processes.

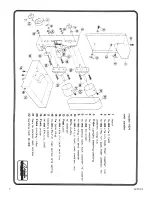

Summary of Contents for 464WBS

Page 7: ...7 2019 01...