1017952-A

Page 12

BURNER

NATURAL GAS - (SPECIFIC ELEVATIONS)

HEDV253A

HEDV403A

HEDV254A

HEDV404A

51

45

58

55

52

47

60

55

52

48

62

56

53

49

63

56

54

50

64

57

0 to

2,000’

0 to

2,000’

Model No.

Model No.

4,000 -

6,000’

4,000 -

6,000’

2,000 -

4,000’

2,000 -

4,000’

6,000 -

8,000’

6,000 -

8,000’

8,000 -

10,000’

8,000 -

10,000’

PROPANE GAS - (SPECIFIC ELEVATIONS)

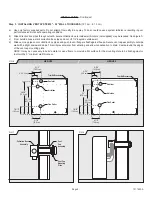

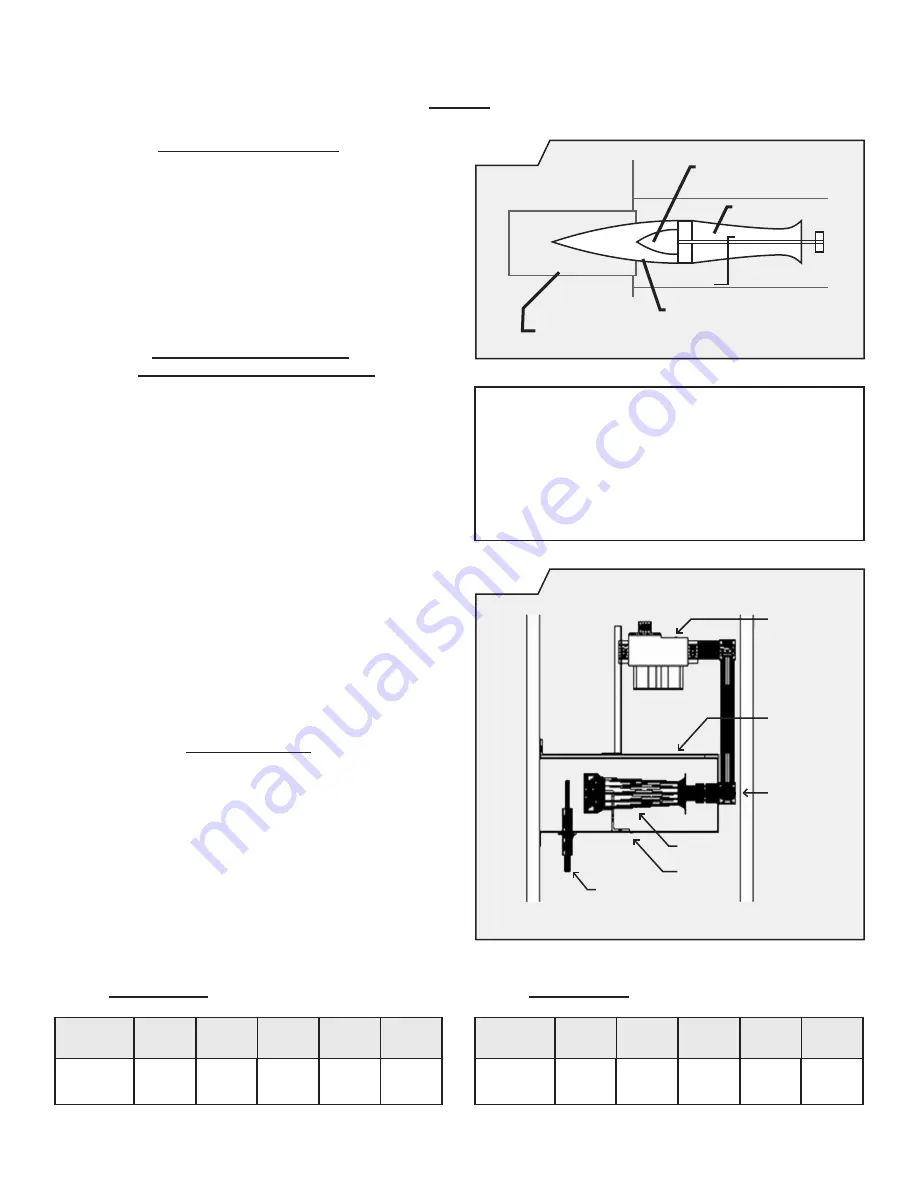

The burner flame may be observed by raising the sight glass

cover. A proper flame will have a dark blue inner mantle,

with a lighter blue outer mantle that extends from the burner

into the heat exchanger tube,

(see Figure 11).

There is no primary air adjustment on the burner, and

proper flame is assured since the correct manifold pressure

and orificing have been done at the factory.

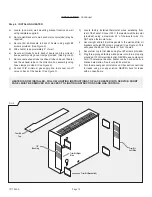

TO REMOVE MAIN BURNER

FOR INSPECTION AND CLEANING

1. Turn off all electrical supply to heater.

2. Turn off gas supply.

3. Remove front panel.

4. Unplug wire to direct spark ignitor and sensor.

See Figure 12.

5. Disconnect vacuum hose from burner box.

6. Remove screws holding burner box top to burner box.

See Figure 12.

7. Remove burner plate and burner box top. Take care not

to contact, or strain ignitor in any way as it is extremely

fragile.

See Figure 12.

8. Remove 2 nuts holding burner bracket.

See Figure 12.

9. Slide burners toward heat exchanger and lift up from

rear and back.

See Figure 12.

10. Clean or replace as needed.

11. Reinstall by reversing Steps 9–1.

FIG. 11

Primary Flame

Secondary Flame

Heat Exchanger Tube

Burner

FIG. 12

NOTE: The furnace and all components must be

inspected at least annually by a qualified service

technician.

This should include the burner, heat

exchanger, and vent system. Be sure that the flow

of combustion and ventilation air are not obstructed

and that all hoses are undamaged, and all clamps

are securely tightented.

PROPER BURNER FLAME

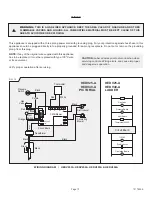

This appliance equipped only for altitudes 0 - 2,000 ft.

Appliance input ratings are based on sea level operation

and need not be changed for operation up to 2,000 feet

(609.9 m) elevation. For operation at elevations above

2,000 feet (609.9 m).

The BTU input must be reduced 4% per 1,000 ft. Orifice

change must be completed by a qualified installer or service

technician. See the following orifice chart for the proper

orifice drill size for a specific elevation.

BURNER ORIFICE

Direct

Spark Ignitor

Burner

Bracket

Burner

Burner

Box Top

Manifold

Maxitrol

Gas

Valve