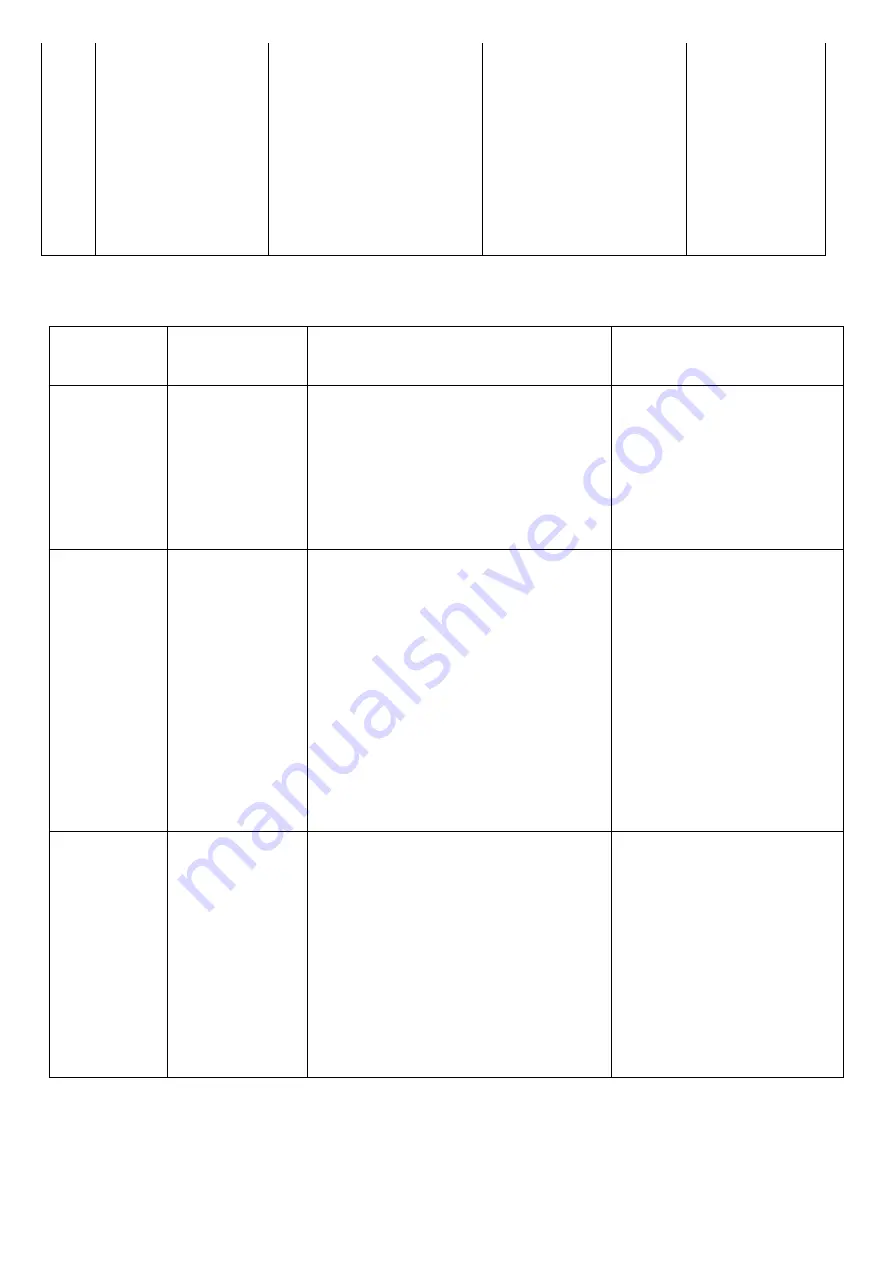

25

when start the

backrest recline

actuator, there is no

counting signal for

more than 2.5 seconds

1.backrest recline actuator is

broken

2.backrest recline actuator

wire is disconnected

3.the signal wire of the

backrest recline wire is

disconnected

1.change backrest recline

actuator

2.check whether the

backrest recline actuator

motor wire is well

connected.

3.check whether the signal

wire of the backrest recline

actuator is well connected

activate

auto-check model

2.2 Common Troubles and Maintenance Methods are listed as following:

Serial NO.

Phenomenon

Description

Maintenance Methods

01

No Function When

Starting.

The LCD isn’t illuminating:

①

Fuse melts (in the Power Source Box or on

the transformer wire).

②

Power supply circuit poorly connected.

③

main PCB fails.

①

Replace Fuse.

②

Replace Power Box.

③

Replace main PCB.

02

No function when

starting.

The LCD is illuminating

:

①

Mechanical switch fails or it’s wire is

opened.

②

Up or Down Stroke Photo-electricity fails.

③

Main PCB fails.

④

Kneading is on without pressing any key

when starting and no response by pressing

other keys.

①

Replace mechanical switch or

it's wire.

②

Replace Stroke Photo-

electricity.

③

Replace the main PCB.

④

Width Inspection Board of

PCB fails, replace it.

03

No Width

switchover.

①

The terminals of Width Inspection on main

PCB and wires are poorly connected.

②

The terminals of Width Inspection on

massage mechanical and wires are poorly

connected.

③

Width Inspection fails.

④

Main PCB fails.

①

&

②

Plug the terminal securely

or replace the wires.

③

Replace Width Inspection.

④

Replace the main PCB.