8

1. It is recommended the manifold be opened to

the atmosphere before every working session.

If display reads other than zero in the selected

pressure units, zero can be re-set by pressing

and holding [CLR] at main screen. The Pressure

Zero Screen [FIG.7] appears and will then

return user to Main Screen [FIG.1], where

both Pressure Displays should now read zero.

This operation should be performed especially

if manifold has been dropped or pressurized

beyond 800 PSIG (55 bar) full scale.

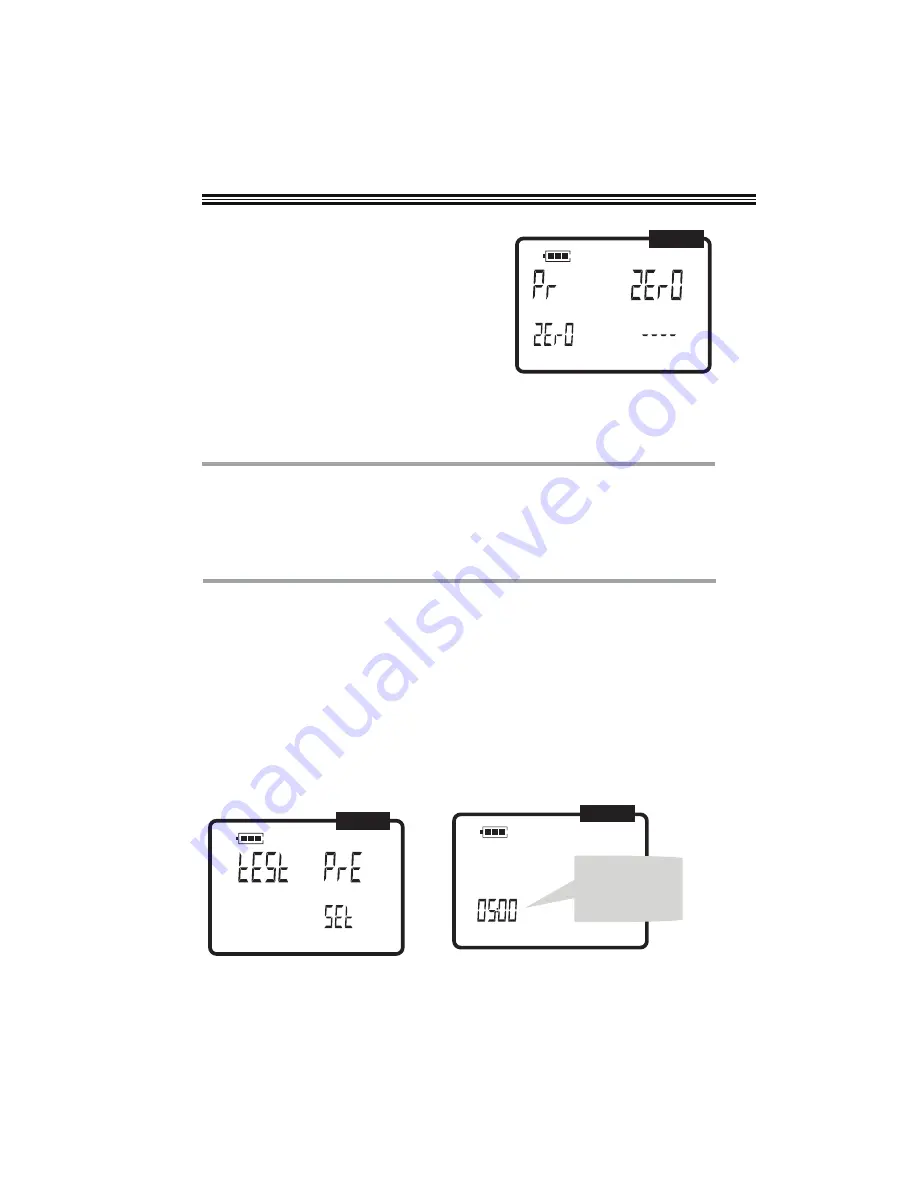

SETTING TO ZERO PRESSURE

Pressure Zero Screen

APO

FIG.7

PRESSURE HOLD TEST

A pressure hold test should be used to determine if a large leak exists (not to determine

if no leak or small leaks exist). Electronic Leak Detectors are the only instrument to

determine leak rates less than 1 oz./year. In practice there should be no pressure hold

detected if the system is deemed leak proof enough to add refrigerant. Large leaks

should be found before adding refrigerant. Low cost tracer gas mixtures such as 95%

N2 and 5% H2 are popular and can be sensed by a CPS E_MOS leak detector.

1. At Main Screen [FIG.1] press [TEST]. The Test Pressure Set Screen will appear

[FIG.8]. [Note: The MDXVG Vacuum Gauge accessory should not be plugged in

at this time].

2. Press [SET] to advance to Test Time (Pressure) Set Screen [FIG.9].

Test Pressure Set Screen

APO

FIG.8

hh : mm

APO

Test Time Pressure Set Screen

Adjust Test

Duration In 5

Minute Increments

FIG.9

PRESSURE HOLD OR VACUUM HOLD TESTING

The BLACKMAX MD100 and MD50 series manifold can perform Pressure Hold and

Vacuum Hold tests. Test pressures and durations are fully settable by the user. Any

test can be aborted at any time by pressing [CLR].

www.

GlobalTestSupply

.com

Find Quality Products Online at:

sales@GlobalTestSupply.com