9

PRESSURE HOLD TEST (CONTINUED)

3. Use [UP/DOWN ARROWS] to adjust test duration in 5 minute increments to

desired setting (Note: Minimum time is pre-set at 5 minutes. Maximum time is

95 minutes).

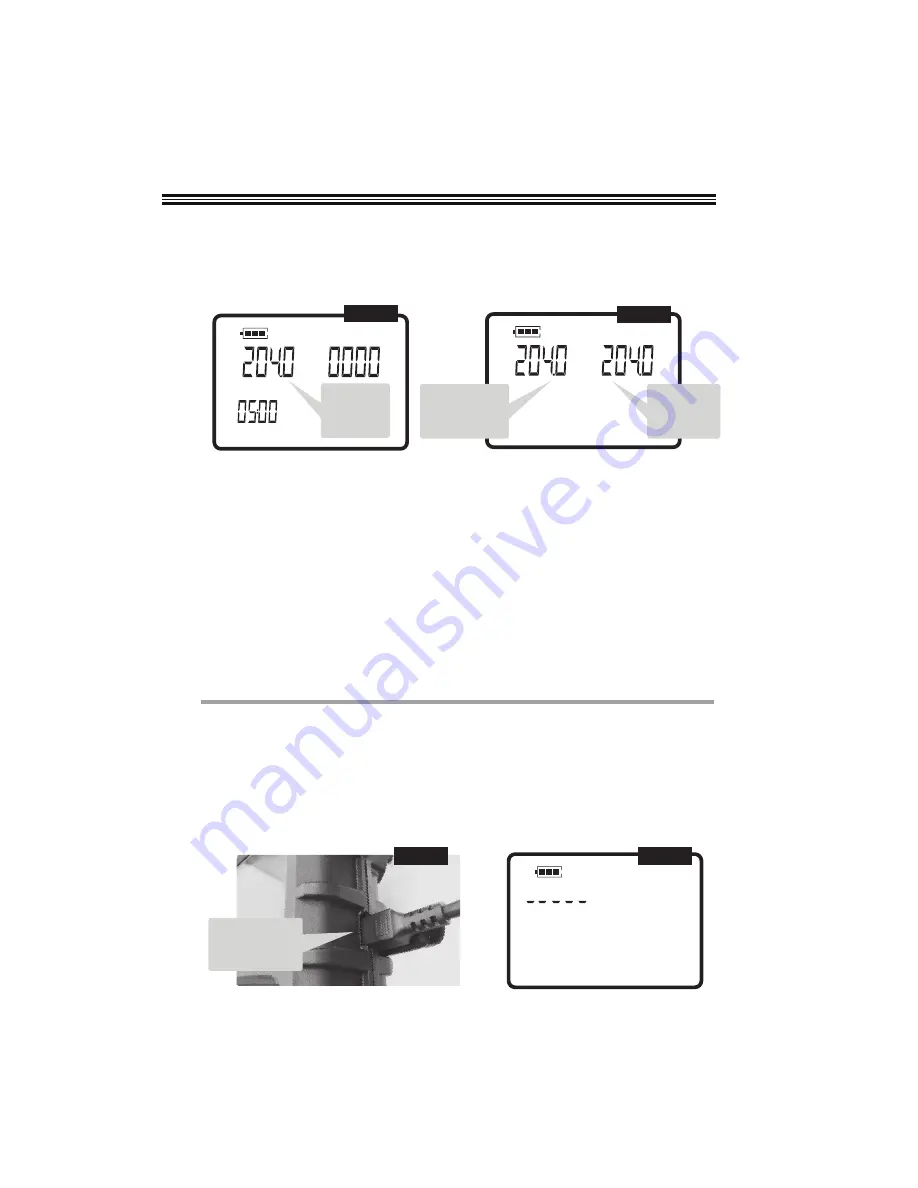

4. Press [SET] to store Test Duration. Display will advance to Pressure Set Screen [FIG.10].

hh : mm

Psig

Pressure Set Screen

Input Test

Pressure

FIG.10

Psig

Psig

APO

Start Vs. Final Pressures

FIG.11

Original Set

System Pressure

Value

Final System

Pressure

Value

5. Connect manifold Low and High Side Service hoses to the system to be tested.

Pressurize the system. Regulated Nitrogen or Nitrogen/Hydrogen trace gas is

recommended.

6. The pressure in the system will be displayed in the UPPER LEFT.

7. Press [SET] to start test. Starting test pressure is indicated in upper left display

[FIG.10]. Current system pressure is shown in upper right display. Timer (lower left

display) decrements and when at zero, a bell will sound indicating test completion

and Start Vs. Final Pressures will be displayed [FIG.11] to determine if system

leaks.

VACUUM HOLD TEST

Normally, systems with vacuum levels within 250-500 microns are deemed as having a

good seal and are ready for charging. As with any recharged system, a good electronic leak

detector should be used to test for leaks after the charge has been completed. MD50 or

MD100 manifold series will function as accurate vacrometers when used with the MDXVG

Remote Vacuum Accessory [FIG.4].

1. Plug the MDXVG Vacuum Accessory into the upper right side of the manifold [FIG.12].

2. The Vacuum Display Screen [FIG.13] appears.

MDXVG Vacuum Gauge Accessory Connection

Connection port

FIG.12

Vacuum Display Screen

Vac

mic

FIG.13

www.

GlobalTestSupply

.com

Find Quality Products Online at:

sales@GlobalTestSupply.com