8.0 TROUBLESHOOTING

8.1 Electric Machine Troubleshooting

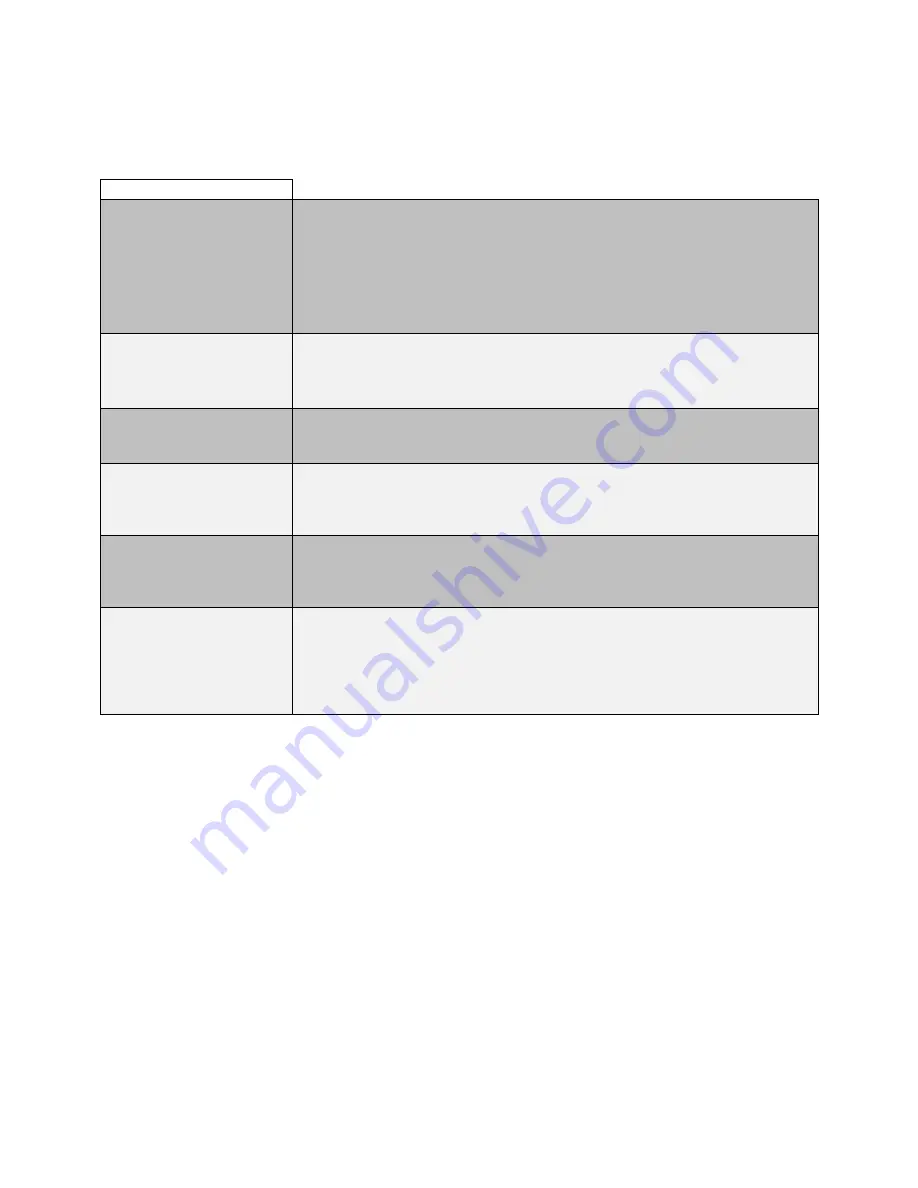

Symptoms

Failure to Start

•

Ensure that the power cord is securely plugged in.

•

Make sure the prongs on the cord are making good contact with the

outlet.

•

Check that all phase indicator diodes are lit up.

•

Check the speed you are starting on.

•

Press

Reset

if the

Stop

button was pressed.

Stops Suddenly

•

Check to see if the cable is hot. If it is hot, the cable may be too long

or have too small a cross-sectional area.

•

Reduce speed. The machine may have been continuously run at

high speed with an inefficient electrical supply.

Vacuum Not Working

•

Check that hoses are fastened securely and that vacuum is

functional.

Head Does Not Turn

•

Check belt tension.

•

If the fan on the engine is running but the head is not turning, the

belt is slipping or broken. Call CPS for service.

Heads Spin, Housing

Doesn’t

•

If the head spins, but the housing doesn’t, the pinion gear shear pin

has broken. Test it by turning the head manually. The housing

should tun.

•

Machine is Vibrating or

Running Unevenly

•

Check for uneven wear on diamonds. If the heads are not running

evenly, rebuild Flex Heads.

•

A concentration of dirt can cause the driving plates to become hard

and inelastic. Clean the machine between the housing and heads.

•

Check that grinding tools are properly positioned and not too worn.

For all other error codes your machine may display, contact CPS at 877.472.8200 or

your certified service technician.

Repairs

All repairs for CPS machines must be completed by a CPS authorized service technician.

Contact CPS or your retailer to locate certified service centers. Repairs must be completed by

trained specialists, authorized by CPS to complete machine repairs. Failure to use a certified

service technician may result in a voided machine warranty