8.0 TROUBLESHOOTING

8.1 Propane Machine Troubleshooting

The Propane Rover grinder from Concrete Polishing Solutions is designed to be inherently

low-maintenance

and to perform for long periods without extensive troubleshooting in the field. If difficulty is encountered,

refer to the following:

Should you still have difficulty, contact CPS at 877.472.8200 for assistance, 24/7.

8.2 Repairs

All repairs for CPS Machines must be completed by an authorized CPS service technician. Contact CPS or your retailer to locate

certified service centers. Repairs must be completed by trained specialists who have been authorized by CPS to repair our machines.

Failure to use a certified technician may result in a voided warranty.

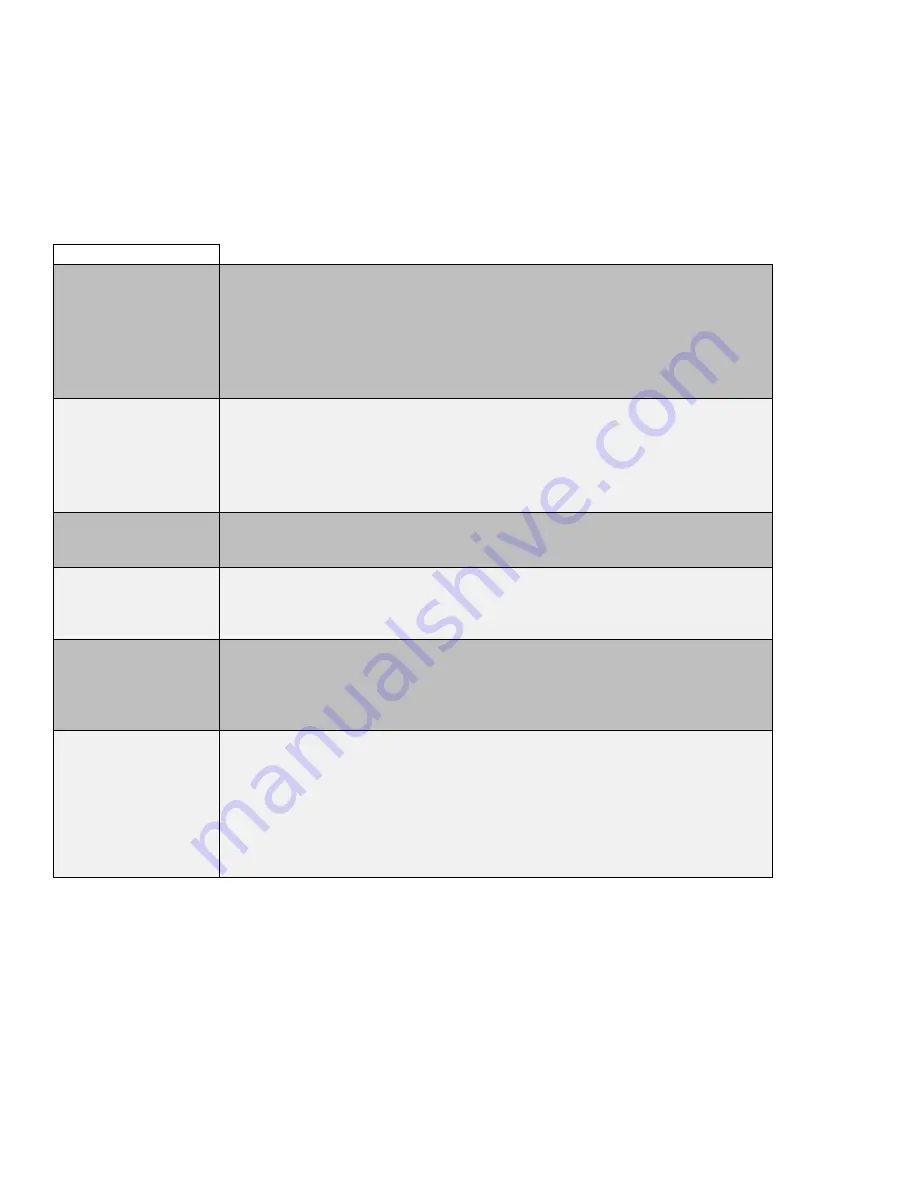

Symptoms

Failure to Start

•

Ensure there is adequate propane in the tank

•

Ensure the E-Stop button is disengaged.

•

Check the battery for a charge.

•

Check to ensure the oil level is correct.

•

Check the speed you are starting at. Start at a low speed and slowly build

to higher RPMs.

Stops Suddenly

•

Ensure there is adequate propane in the tank

•

Make sure the tank is not overfilled. (80% full maximum)

•

Make sure you are using a vapor draw tank. CPS machines will not

function with any other propane tank.

•

Be sure that exhaust is not covered or blocked.

•

Ensure there is adequate ventilation.

Vacuum Not

Working

•

Check that hoses are fastened securely and that vacuum is functional.

Head Does Not Turn

•

Check belt tension.

•

If the engine is running and the head does not turn, contact CPS for

certified service providers who can assist you.

Heads Spin,

Housing Doesn’t

•

If the heads spin, but the housing doesn’t, it’s likely that a pinion gear

shear pin has broken.

•

Test to see if shear pin has broken by turning one of the heads while the

machine is shut off. The housing should turn if the machine is functional.

If it isn’t call CPS to find a certified service provider to assist you.

Machine is Vibrating or

Running Unevenly

•

Turn machine off.

•

Tilt machine to check evenness of heads.

•

If the heads are not running evenly, rebuild heads.

•

Check for uneven wear on diamonds.

•

Check that the grinding tools are not worn down and that they are

properly positioned on the wheel.

•

A concentration of dirt causes the driving plates to become hard and

inelastic. Clean the machine between the housing and heads.

Summary of Contents for Rover VacPac

Page 1: ...Operator s Manual Rover VacPac ...

Page 2: ......

Page 9: ...4 2 Rover Electric Machine Diagram ...

Page 15: ...Fig 2 Joystick Control on CPS Rover The circled portion is the On Off button ...

Page 21: ...10 1 Rebuilding Flex Heads ...

Page 22: ...10 2 Oil Changes ...

Page 23: ......

Page 24: ...10 3 Changing the Oil Filter ...

Page 25: ...10 4 Air Filter Service ...

Page 26: ...10 5 Greasing the Ring Gear ...

Page 27: ...10 6 Adjusting the Regulator ...

Page 28: ...10 7 Changing the Spark Plugs ...

Page 29: ......