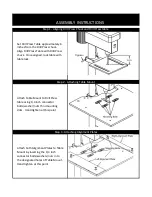

After preparing the material you can proceed to setting up the Circle Guide and Drill Press.

Step 1:

Step 2:

Move the Slide Plate away from the drill bit until it is stopped by the Lock-Down Bolt.

Step 3:

Step 4:

Step 5:

Step 6:

Step 7:

Step 8:

Step 9:

Step 10:

Drilling Holes in Material (with Degree Gears)

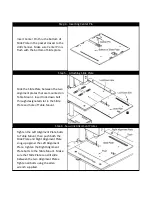

Start by releasing the Alignment Pin and loosening the Lock-Down Bolt.

Insert the desired drill bit into the Drill Press.

Lift material off the Center Pin and place aside.

Move the Slide Plate into desired position in order to set the radial distance. If using a set

measurement, insert the Alignment Pin into set measurement position and then tighten the Lock-

Down Bolt. If not using a set measurement, simply tighten the Lock-Down Bolt at current position.

Turn on Drill Press and proceed to drilling a hole. Release the Rotation Alignment Pin and rotate

material when drill bit is raised. Lock into next Degree Gear slot and drill another hole. Continue

this process to drill holes in a circular pattern at the current radial distance. Repeat steps as

needed.

Attach the desired Degree Gear by first placing the material onto the Center Pin using 1/8"

(English) or 3mm (Metric) hole (bottom of material facing up). Place double-sided tape on smooth

side of Degree Gear and then place onto material using the Center Pin (gears facing up).

Place the Rotation Plate on top of the Slide Plate using Center Pin and ensure it seats into position.

Now place material back onto the Center Pin with Degree Gear facing down. Ensure the Degree

Gear seats into the designated hole in the Rotation Plate.

Insert the Rotation Alignment Pin into the Rotation Plate and lock into the Degree Gear slot.

NOTE: You can also mount using screw holes in Degree Gear instead of double-sided tape.

Summary of Contents for CPDP-104

Page 10: ......