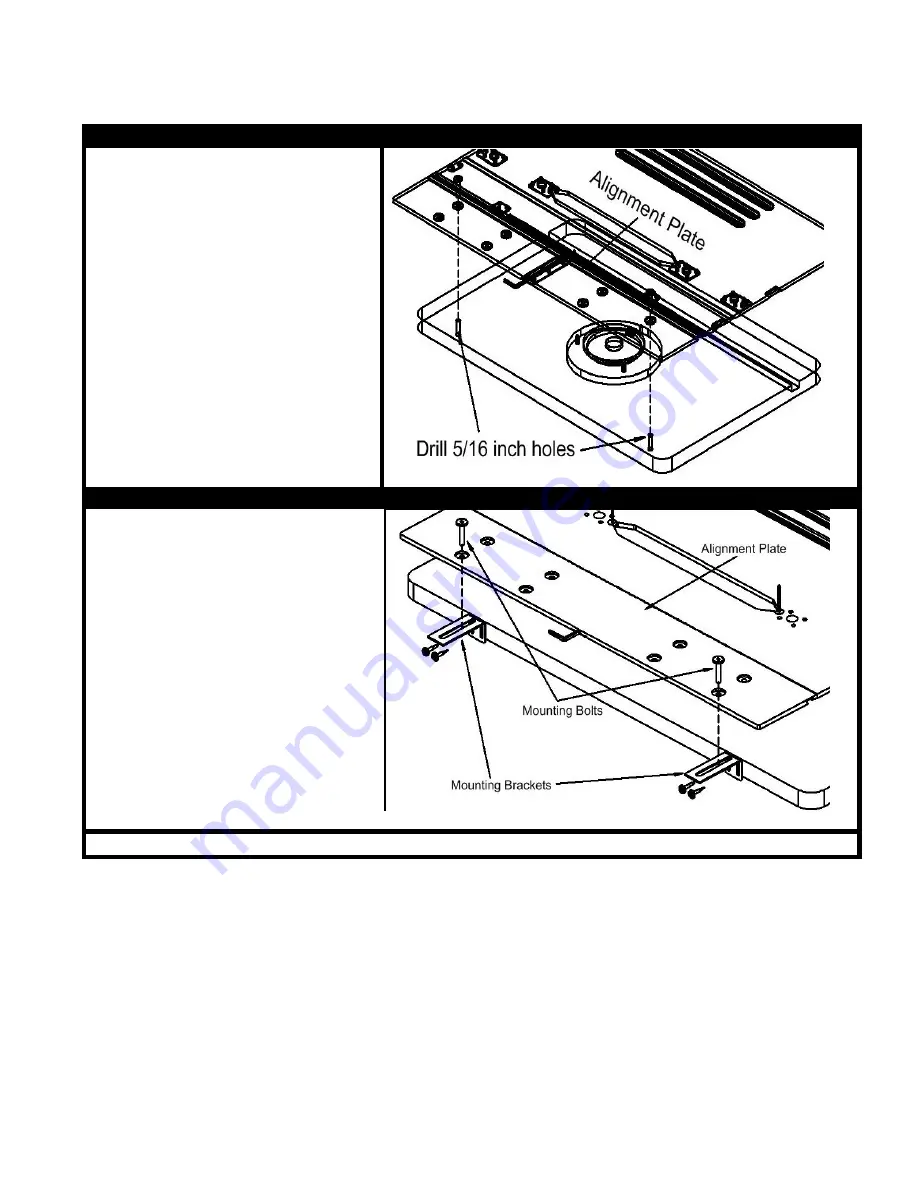

Step 7 Option B - Attaching Alignment Plate - USING MOUNTING BRACKETS

Step 7 Option A - Attaching Alignment Plate - USING BOLTS

Using a 5/16 inch drill bit, drill

two holes into the router table

(one from each side) matching

the pre-drilled holes in

Alignment Plate. Insert

mounting bolts through both

the Alignment Plate and router

table and use Hex Key to

secure with washers and hex

nuts.

(Note: multiple “sets" of holes

are pre-drilled in Alignment Plate to

accommodate different sizes of router

tables)

Mount two metal brackets (one

on each side) to the

back

edge

of router table by aligning the

brackets with the pre-drilled

holes in the Alignment Plate.

Insert mounting bolts through

Alignment Plate and metal

mounting bracket and secure

with washes and nuts.

(Note:

multiple “sets" of holes are pre-drilled to

accommodate different sizes of router

tables)

Summary of Contents for CPRT-104

Page 10: ......