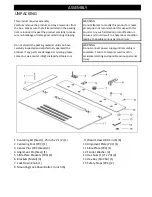

Step 1:

Loosen the Lock-Down Bolt and release Alignment Pin.

Step 2:

Move the Slide Plate to desired measurement position.

Step 3:

Insert Alignment Pin into Slide Plate (should click into position).

Step 4:

Tighten the Lock-Down Bolt and ensure the Slide Plate is held firmly in position.

Step 5:

Perform cut and repeat as necessary.

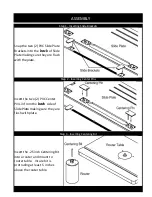

Step 1:

Loosen the Lock-Down Bolt and release Alignment Pin.

Step 2:

Move the Slide Plate to desired position.

Step 3:

Tighten the Lock-Down Bolt and ensure the Slide Plate is held firmly in position.

Step 4:

Perform cut and repeat as necessary.

Tip 1:

Tip 2:

Tip 3:

Tip 4:

It is recommended to perform multiple cuts and not perform a single cut where the bit protrudes

all the way through the material. The best practice is to make cuts as deep as only 1/2 of the

diameter of the bit at a time.

When using harder material, ensure the material does not overheat from excessive routing as this

may cause damage to the surface of the Circle Guide tool.

It is recommended to remove debris such as saw dust from the Alignment Plate channel routinely

to provide smooth sliding operation.

Tips

To prolong the life span of the tool's surface, make sure to remove any abrasive particles and/or

spurs from face of material before routing to prevent damage to the surface of the Circle Guide

tool.

The Circle Guide for Router Table provides the ability to set the Slide Plate into positions simply by moving

Slide Plate into desired position and ONLY tightening the Lock-Down Bolt. This provides "infinite" positions

between the minimum and maximum radius settings allowing operator to make incrementally small

adjustments (i.e. shave edge) or set Slide Plate into a position which cannot be locked into by using the

Alignment Pin.

The Circle Guide for Router Table provides the ability to lock in at set measurements every 1/16" (English) or

2mm (Metric). This operation provides precise repeatability by allowing operator to recall to a prior position.

Using Set Measurements

Using Infinite Variability

Summary of Contents for CPRT-104

Page 10: ......