Super Shot 60 Propane Melter Part Manual

Chapter 8 Troubleshooting

©2018 by Crafco, Inc. All Rights Reserved

………………...…………………………..……………...Illustrated Parts List 8-24

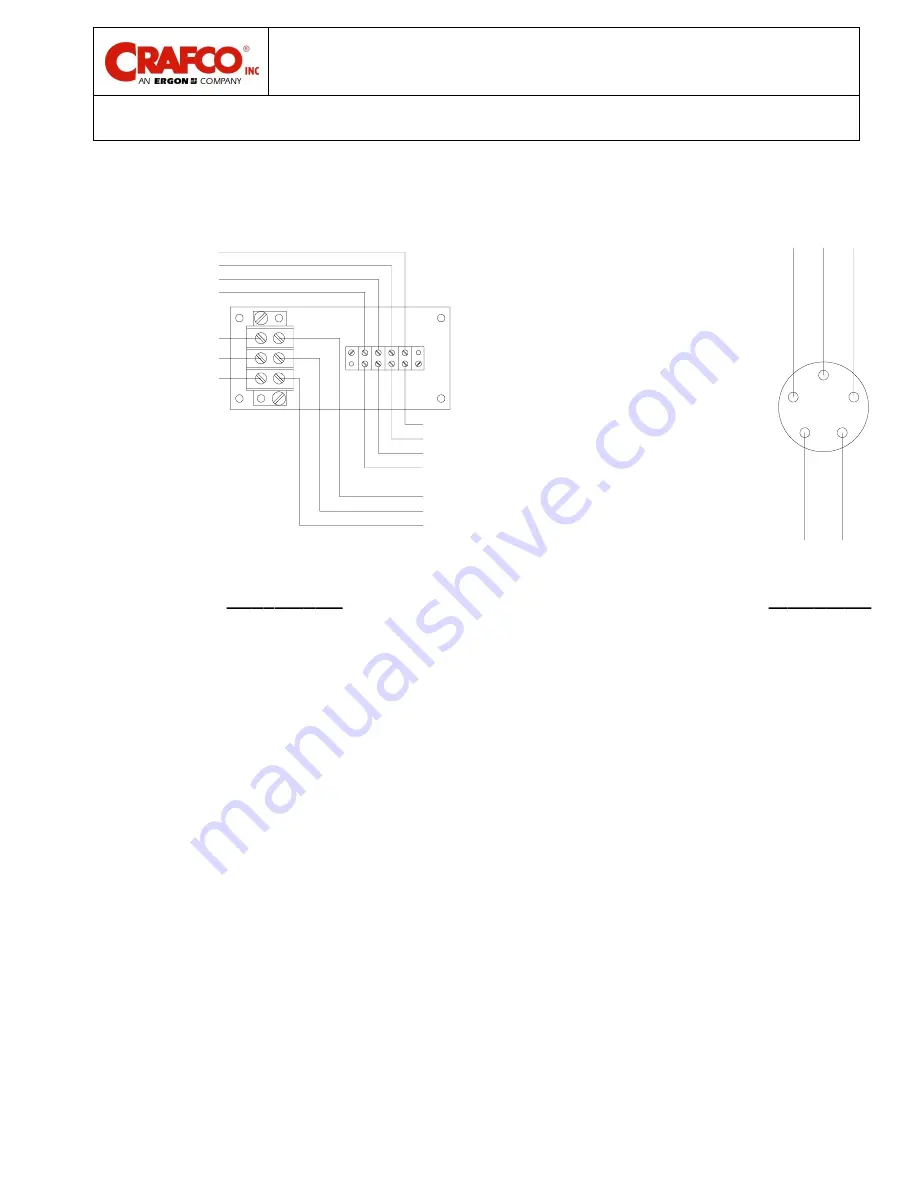

Fig. 8-8 Junction Box Wiring

HEATER BLACK

HEATER WHITE

HEATER GREEN

SENSOR WHITE

SENSOR BLACK

TRIGGER GREEN

TRIGGER RED

HEATER BLUE

TRIGGER RED

TRIGGER RED

SENSOR BLACK

SENSOR WHITE

HEATER BLUE

HEATER BLUE

T

R

IG

G

E

R

(

R

E

D

)

T

R

IG

G

E

R

(

R

E

D

)

C

B

H

E

A

T

E

LE

M

.

(B

L

U

E

)

H

E

A

T

E

L

E

M

. (

B

LU

E

)

H

E

A

T

E

L

E

M

.

(B

LU

E

)

E

D

A

KETTLE END

WAND END

Summary of Contents for SUPER SHOT 60

Page 1: ...Parts Manual 26616 Revision C SUPER SHOT 60 PROPANE MELTER ...

Page 4: ...Super Shot 60 Propane Trailer Melter PN 43300 Super Shot 60 Propane Skid Melter PN 50750 ...

Page 14: ......

Page 22: ......

Page 62: ......

Page 66: ......

Page 102: ......

Page 136: ......

Page 139: ......

Page 140: ... 2018 Crafco Inc ...