7

Before starting setting up the machine

you need to read and understand this

user manual completely. For the

protection of your eyes you need to have

safety glasses. The unpainted surfaces of

the lathe are coated with rust prevention

waxy oil and you will want to remove this

before you begin assembly. Use a solvent

cleaner that will not damage painted

surfaces.

Unpacking

The machine is properly packaged in a

carton for safe transportation. When

unpacking, carefully inspect the crate and

ensure that nothing has been damaged

during transit. Open the crate and check

that the machine is in a good condition.

There is a bag which contains some loose

parts of the machine. After the machine

has been un-packed, check that all loose

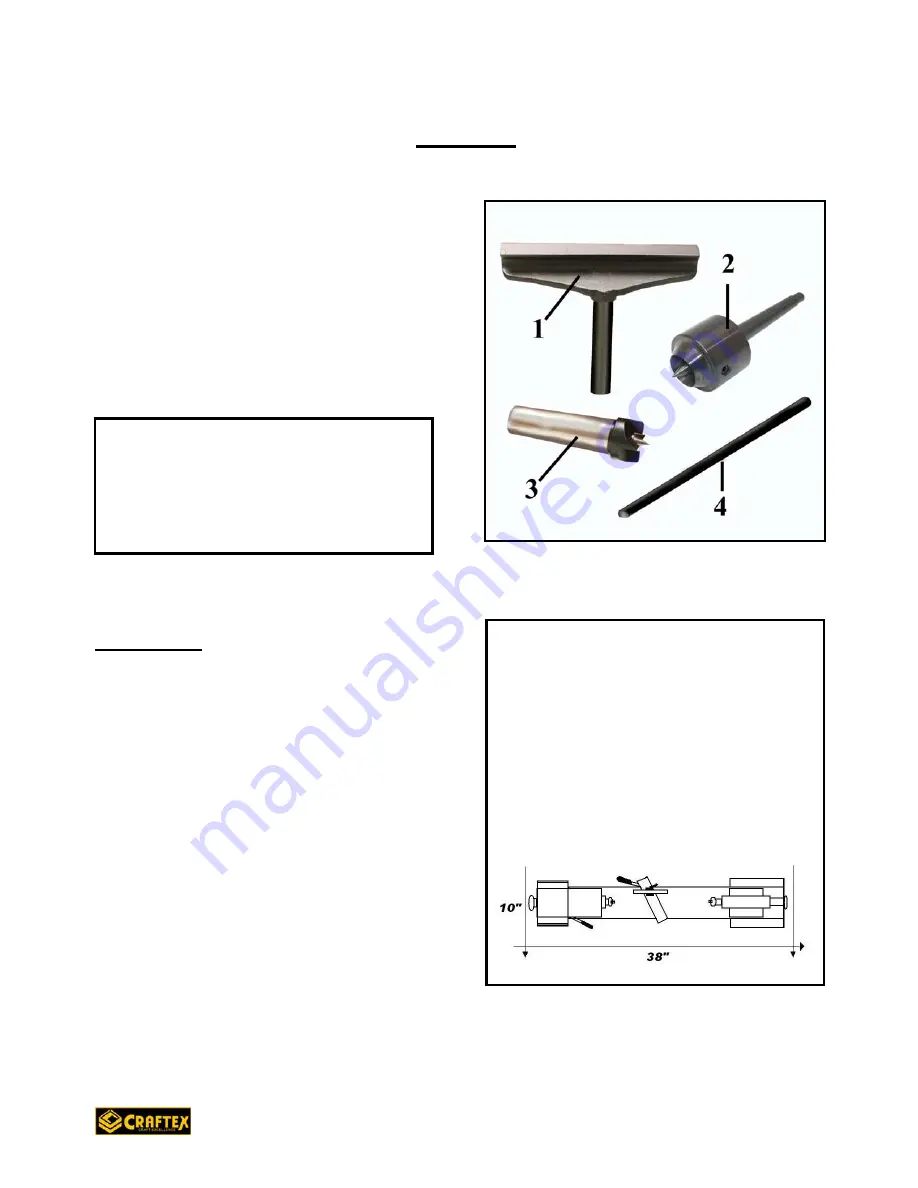

parts shown in Figure-1 are present.

1. Tool Rest

2. Tailstock Center (Live Center)

3. Headstock Center (Dead Center)

4. Center Knock-Out Bar

Figure-1 Loose parts

CT160 weighs approximately 106 lbs.

Do not over-exert yourself. For safe

moving method use fork truck or get

the help of an assistant or friend.

When setting up your machine, you will

want to find an ideal spot where your

machine will most likely be positioned

most of the time. Consider

your

complete work environment as well as

working comfortable with the lathe

before placing your machine in the

ideal spot. The figure below shows

minimum workplace for the lathe.

SETUP

Summary of Contents for CT160

Page 1: ...CT160 HEAVY DUTY BENCH TOP LATHE User Manual ...

Page 6: ...6 PHYSICAL FEATURES ...

Page 17: ...17 CT160 HEAVY DUTY BENCH TOP LATHE PARTS BREAKDOWN ...

Page 18: ...18 CT160 HEAVY DUTY BENCH TOP LATHE PARTS LIST ...

Page 19: ...19 CT160 HEAVY DUTY BENCH TOP LATHE PARTS LIST ...

Page 20: ...20 CT160 HEAVY DUTY BENCH TOP LATHE PARTS LIST ...

Page 21: ...21 CT160 HEAVY DUTY BENCH TOP LATHE PARTS LIST ...

Page 22: ...22 CT160 HEAVY DUTY BENCH TOP LATHE PARTS LIST ...