11

AGAINST THE ROTATION OF THE

WHEEL

Grinding against the rotation of the wheel

removes a large amount of material in a

very short time and finally the result will not

be very smooth. Coarse tools are

sharpened against the rotation of the wheel.

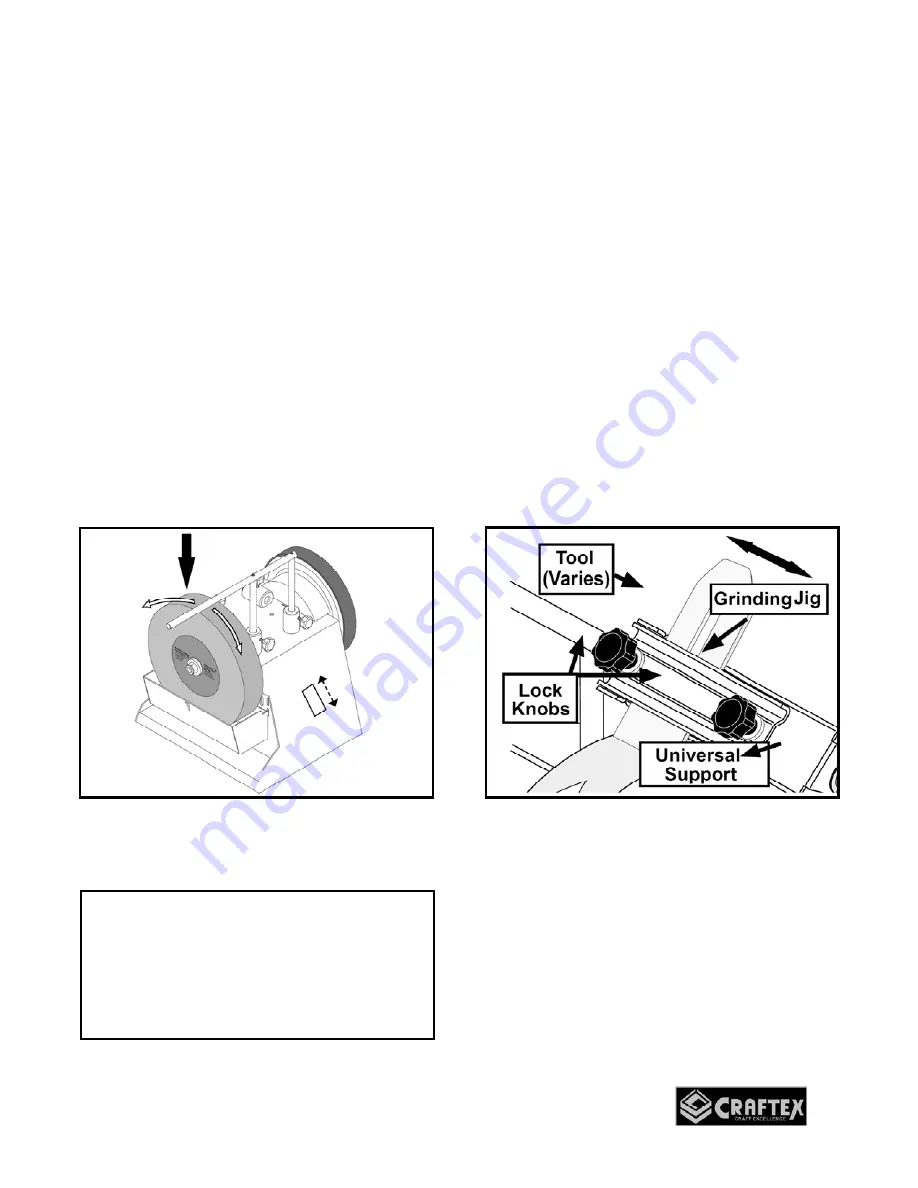

To set the universal support for grinding

against the rotation of the wheel:

Turn the switch to OFF position and make

sure the cord is unplugged from the power

source.

Install the universal support through the

vertical mounts on the grinder and secure it

by tightening the knobs properly as shown

in figure-7.

Figure-7 Installing the universal support

vertically for grinding against the rotation

the wheel

GRINDING JIG

The grinding jig provided with the CT191 is

used for securing a variety of tools, and can

be positioned to grind with and against the

wheel rotation.

To mount the grinding jig:

Disconnect the cord from the power source.

Slide the grinding jig onto the universal

support, as shown in figure-8.

Insert the tool into the jig clamp, then use

the angle guide, as described in the manual

to set the grinding angle.

Once the grinding angle is set, tighten both

the lock knobs to secure the tool in place.

Figure-8 Grinding jig

WARNING!

Do not perform any sharpening job on

the leather honing wheel against its

direction of rotation. Failure to do so will

seriously damage the leather honing

wheel.

Summary of Contents for CT191

Page 1: ...CT191 10 WET BENCH GRINDER USER MANUAL Version 1 0 ...

Page 14: ...14 ...

Page 15: ...15 ...

Page 16: ...16 ...