- 4 -

Fig. 1

Before Cutting and Pump Grease

ATTENTION

Apply

grease into the gear reducer every

week to lubricate the gears

.

Choose super high-density grease.

Grease

location

located at rear of gear reducer

.

Use grease gun

to

pump in grease from grease

nipple.

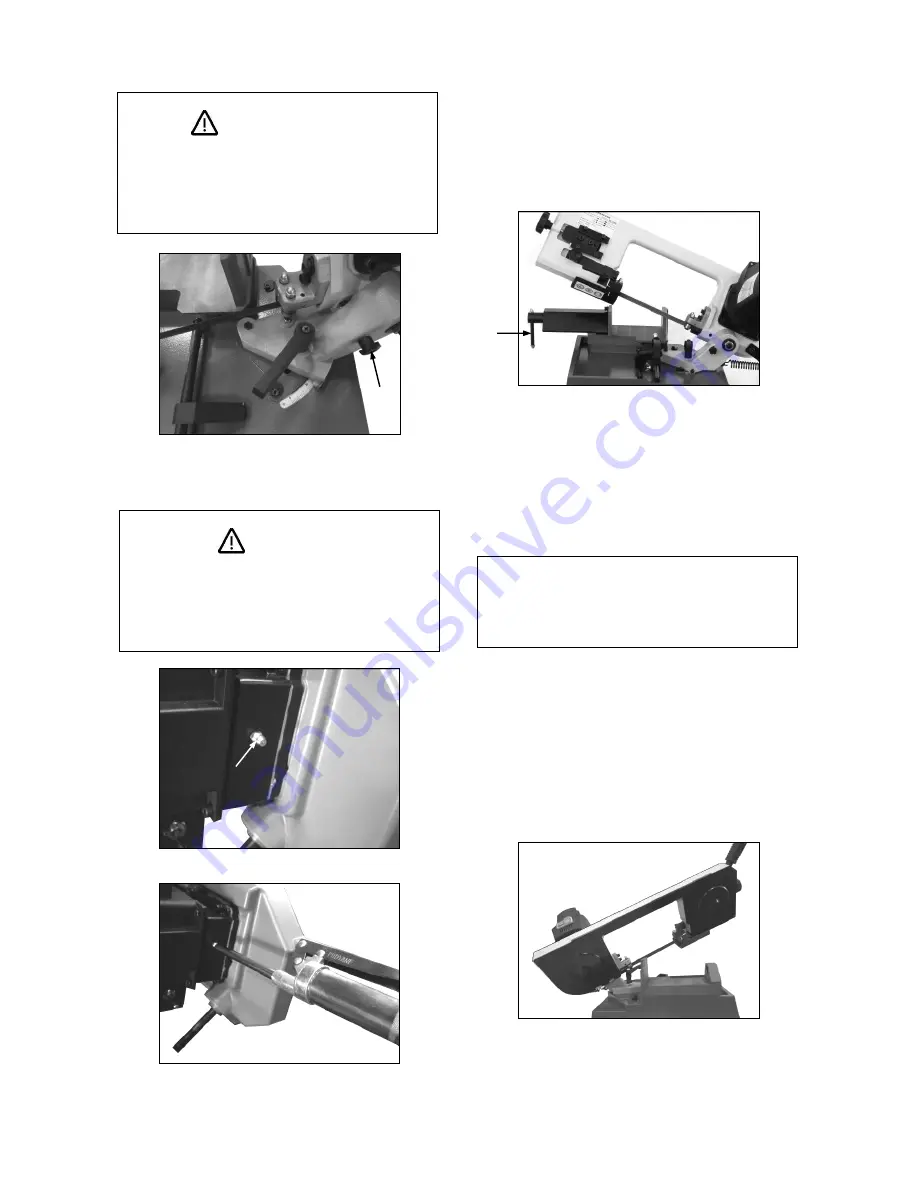

2. The Vise and Work Set Up

Usage of the Vise

The vise is mounted on the machine base.

Follow the

following

steps to open or close the vise.

Fig. 2

1. Turn the handle (A) in Fig.2 counter

clock-wise to open the vise jaw

allowing

the

width of vise

to

load work piece.

2. Make sure the work piece is

placed properly

between

the

jaws

. Turn the handle (A) in Fig.2

clock-wise to close the vise jaw

clamping

the

work piece.

CAUTION !

NEVER OPERATE SAW WITHOUT BLADE

GUARDS IN PLACE.

Work Set Up

1. Raise

the

saw head to proper position in Fig.3.

2. Open vise to accept the

work

piece by

pulling

the hand lever at the end of the

base.

3. Place the work piece on saw bed if the piece is

long, support the end.

Fig.3

BEFORE CUTTING

Release the lock pin (A) in Fig.1 to

release the

saw. After service, must relock

the saw

properly for your safety and carry. Failure to

comply with the warning could result in

personal injury

and damage to the machine

.

A

Grease Nipple

A

Summary of Contents for CX112

Page 1: ...CX112 PORTABLE METAL BAND SAW User Manual Version 1 0 ...

Page 5: ... 3 Electrical Schematic ...

Page 15: ...1030318 V2 SECTION A 13 ...

Page 16: ...1030318 V2 SECTION B 14 ...

Page 17: ...1030318 V2 SECTION C 15 ...