- 7 -

4. Power Supply

Motor Specifications

The DC motor used

with

this saw

features

the

following specifications:

Maximum capacity (kW)

0.30

Voltage (V

dc

) 90

Saw blade speed (MPM)

23~75

Blade rotating direction

counter-clockwise

WARNING:

To avoid electrical hazards,

fire hazard, or damage to the tool, use

proper circuit protection or circuit breaker

to avoid shock or fire, if power cord is

worn or cut, or damaged in any way,

have it replaced immediately.

Noise information according to DIN 45635

No load

under 60 dB

Working 60-65

Db

Grounding

This metal saw is single insulated tool, so the

Grounding system is provided to protect you

from being shocked. The appropriate grounding

system

should be

set up as soon as this machine

is p

lugged into the proper power supply system.

Therefore, the standard power supply system

shall be provided for this machine in order to

protect you from the risk of shock.

DANGER:

To avoid electric shock

1. Do not change the power cord and

plug to another specification not

provided by the manufacturer.

2. Do not use in rain or where floor is

wet. This tool is intended for indoor

residential use only.

Motor Safety Protection

CAUTION:

To avoid motor damage, this

motor should be blown out or vacuumed

frequently to keep sawdust from

interfering with normal motor ventilation.

1. Connect this tool with a fuse or circuit

breaker. Using the wrong size fuse can

damage the motor.

2. If the motor does not start, press the stop

button down immediately. UNPLUG THE

TOOL. Check the saw blade to make sure

it turns freely. If the blade is free, try to start

the motor again.

3. If the motor still does not start that have to

check the motor’s carbon brushes

which

can be used 600~800 hours if carbon

brush has

been worn, please change the new one.

4. If the motor suddenly stalls while cutting

material,

turn the band saw OFF

, unplug

the

power cord

and

remove the work-piece.

Make sure the balde is not in contact with the

work piece, t

hen you may

start the saw

and finish

the cut.

5. Fuses may “blow” or circuit breakers may

trip frequently if:

a.

Motor is overloaded-overloading can

occur if you feed too rapidly or make

too many start/stops in a short time.

b.

Voltage not more than 10% above or

below the nameplate voltage can

handle normal loads. For heavy loads,

however, the voltage (caused by a

small size wire in the supply circuit or

an overly long supply circuit wire) may

drop too low for the motor to operate.

Always check the connections, the

load and the supply circuit whenever

motor does not work well. Check wire

sizes and length with the Wire Size

Chart below.

6. Most motor troubles may be trace to loose

or incorrect connections, overload, low

voltage (such as small size wire in the

supply circuit) or to overly long supply

circuit wire. Always check the connections,

the load and the supply circuit whenever

motor doesn’t work well. Check wire size

and length with the Wire Size Chart below.

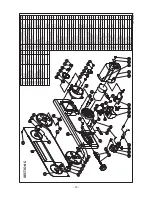

5. Unpacking and Checking

Contents

The Metal Saw is shipped complete in one

carton. Separate all parts from packing material

and check each item with illustration and Make

certain all items are accounted for, before

discarding any packing material.

WARNING:

If any parts are missing, do

not try to assemble the metal saw, plug

in the power cable or turn the switch on

until the missing parts are obtained and

installed correctly.

Summary of Contents for CX112

Page 1: ...CX112 PORTABLE METAL BAND SAW User Manual Version 1 0 ...

Page 5: ... 3 Electrical Schematic ...

Page 15: ...1030318 V2 SECTION A 13 ...

Page 16: ...1030318 V2 SECTION B 14 ...

Page 17: ...1030318 V2 SECTION C 15 ...