7

SETUP

Before starting setting up your machine,

you need to read and understand this user

manual completely.

UNPACKING

The machine is properly packaged in a

carton for safe transportation. When

unpacking, carefully inspect the crate and

ensure that nothing has been damaged

during transit. Open the crate and check

that the machine is in good condition.

The hardware (screws, washers & etc)

might be shipped in a plastic bag. After the

machine has been un-packed, check that

all loose parts and hardware are present.

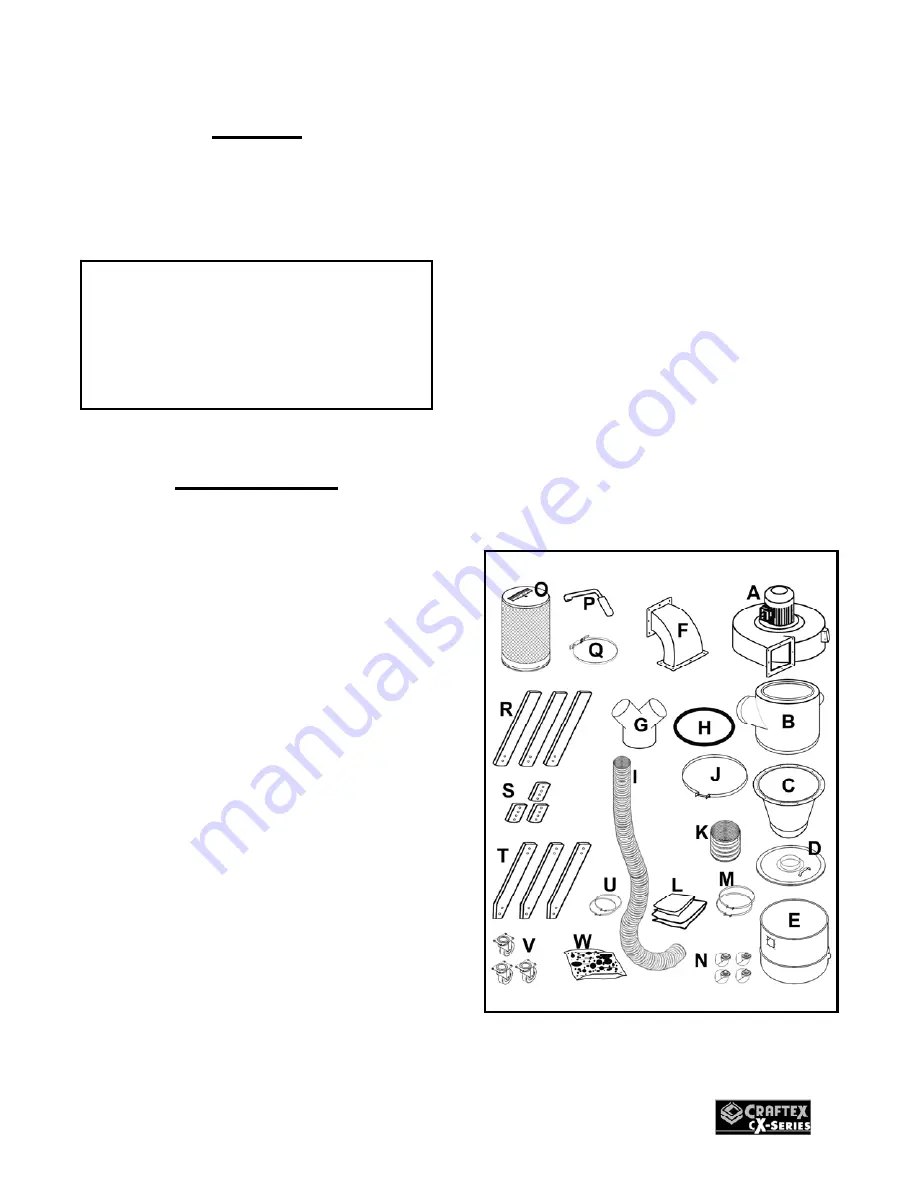

List of Contents

A.

Main Housing ....................................

1

B.

Collector Body ................................... 1

C.

Cyclone Funnel ................................. 1

D.

Drum Lid............................................ 1

E.

Collection Drum................................. 1

F.

Steel Duct Arm .................................. 1

G.

Y-Inlet ............................................... 1

H.

Gasket .............................................. 1

I.

Hose 1-1/2” ....................................... 2

J.

Steel Clamp ...................................... 1

K.

Hose 7” ............................................. 2

L.

Plastic Bags ...................................... 2

M.

Hose Clamp 7” .................................. 2

N.

Castors for Drum............................... 4

O.

Canister ............................................ 1

P.

Canister Cleaning Handle ................. 1

Q.

Plastic Bag Clamp............................. 1

R.

Upper Legs ....................................... 3

S.

Connectors ....................................... 3

T.

Lower Legs ....................................... 3

U.

Hose Clamp 1-1/2”............................ 2

V.

Castors for the Legs.......................... 3

W.

Hardware................................One Bag

Figure-1 Inventory

WARNING

CX401 is a heavy machine. Do not over-

exert yourself. For safe moving method

use fork truck or get the help of an

assistant or a friend.