11

off the machine and investigate to find out

the problem.

If the lathe is running smoothly, let it run for

a few minutes and gradually increase the

RPM using the variable speed control knob

until it reaches the maximum RPM of 2500.

Allow the lathe to run for a few minutes and

stop it by pressing the Emergency Stop

Button.

CHUCK JAWS

REPLACMENT

Replacing the chuck jaws is very simple on

CX704. You just have to pay attention to

the sequence in which the jaws are loaded

into the chuck.

TO REPLACE THE JAWS:

Make sure the cord is disconnected from

the power source.

Remove all the jaws on the chuck by

turning the chuck key counter clockwise.

Clean the jaws and the slot in the chuck

with a piece of cloth and make sure there is

no debris.

The jaws are numbered as A, B, C or 1,2,3

and the numbers are in the slot on the

chuck.

Insert the jaw in to the slot#1 and turn the

chuck key clockwise untill the jaw is

engaged with the thread.

Repeat the same step with jaw#2 and then

jaw#3. Make sure the jaws are installed in

sequence.

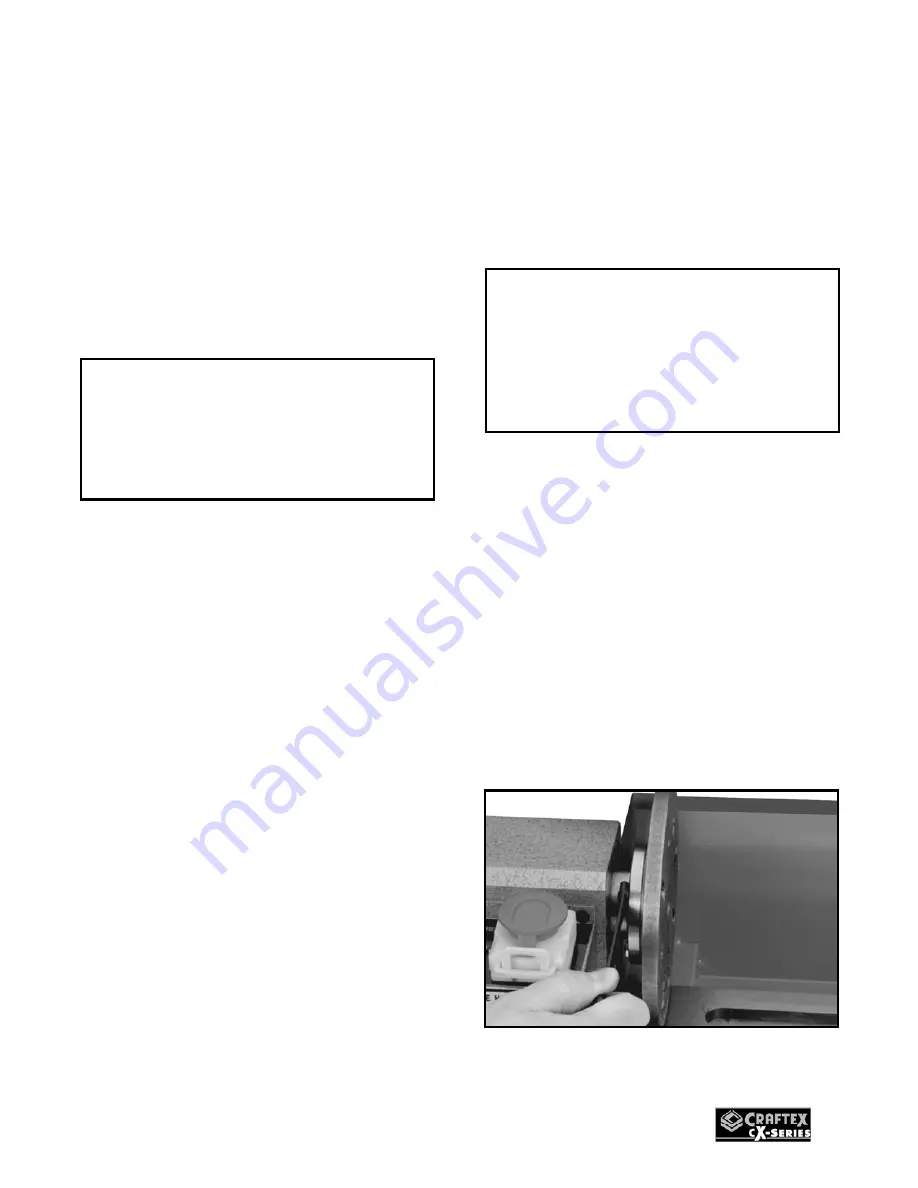

INSTALLING / REMOVING

CHUCK OR FACEPLATE

The chuck is mounted directly to the spindle

nose plate using studs and hex nuts.

TO REMOVE THE CHUCK / FACEPLATE:

Make sure the cord is disconnected from

the power source.

Hold the chuck with one hand and remove

the three hex nuts securing the chuck to the

to the spindle nose plate using a wrench.

Figure-7 Removing the faceplate

WARNING!

DO NOT change the direction of rotation

of leadscrew while the lathe is running.

Failure to do so could result damage to

the lathe.

WARNING!

Make sure not to over-tighten the jaws.

This will damage the jaws. For doing

accentric work, do not install the jaws

into the chuck incorrectly. Always use a 4

jaw chuck for this job.

Summary of Contents for CX704

Page 1: ...CX704 7 x 12 MINI METAL LATHE User Manual ...

Page 21: ...21 WIRING DIAGRAM FOR CX704 ...

Page 22: ...22 ...